Phosphor for white light LED with adjustable emitting peak and its prepn process

An emission peak and phosphor technology, applied in the field of phosphors, can solve the problems of inability to meet the requirements of high-performance devices, narrow half-height widths of excitation and emission peaks, and low effective conversion efficiency of phosphors, and achieves low equipment cost, stable performance, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Ca 0.85 WO 4 :Eu 0.15 The preparation of fluorescent powder, the specific implementation process is as follows:

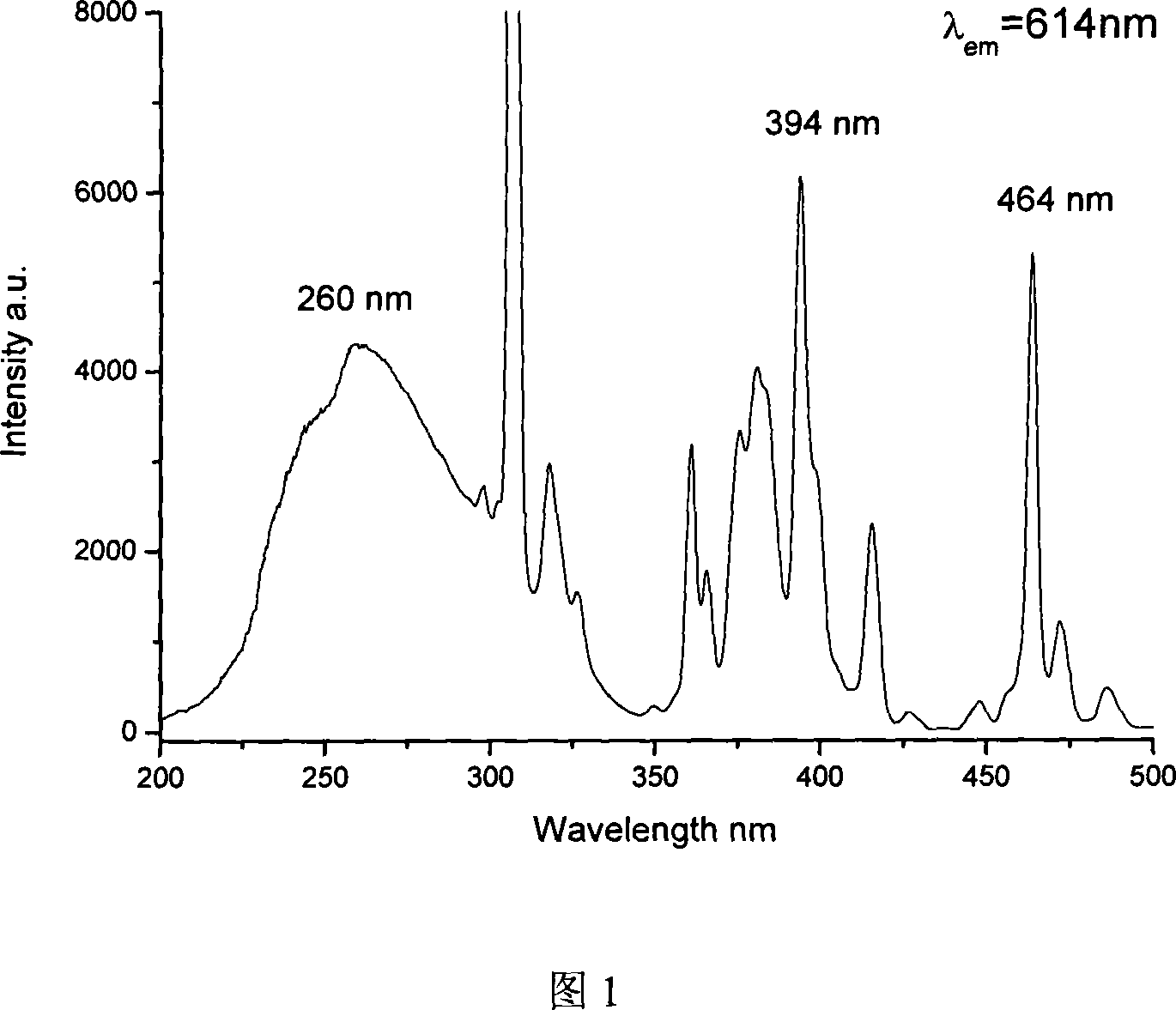

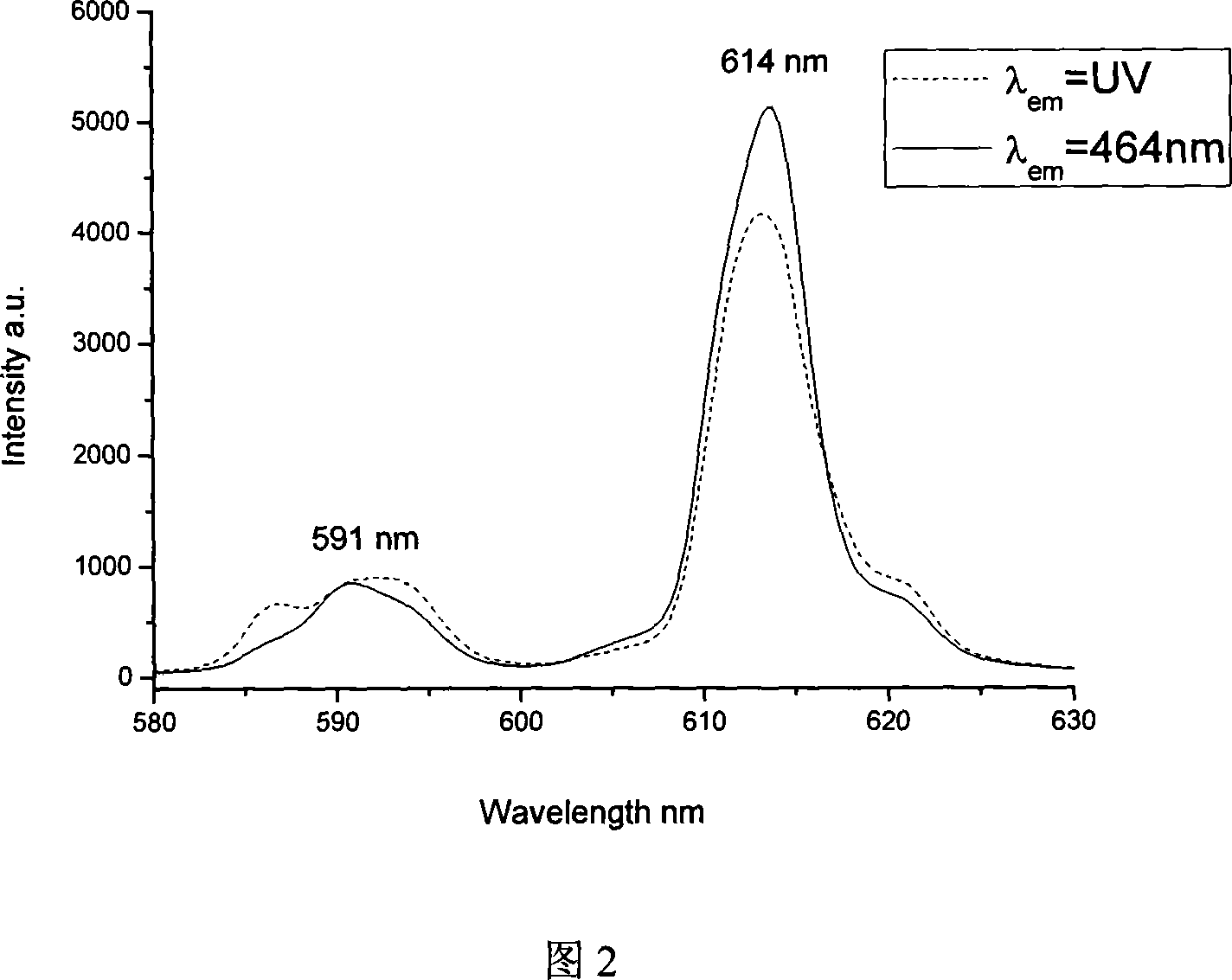

[0032] Weigh CaCO according to the molar ratio of the above stoichiometric formula 3 (AR) 1.7015g, WO 3 (AR) 4.6370g, Eu 2 o 3 (4N)0.5282g, H 3 BO 3 (AR) 0.3433g. After the above-mentioned raw materials are fully ground and uniform, they are put into an alumina crucible and heat-treated in an air atmosphere at 1000°C for 3 hours. The heat-treated product is crushed, washed with water to remove impurities, filtered, and dried at 90°C to obtain the chemical composition of Ca 0.85 WO 4 :Eu 0.15 of red phosphor. The excitation spectrum is shown in Figure 1, the emission spectrum is shown in Figure 2, and the fluorescence data are shown in Table 1. It can be seen from the chart data that the phosphor can be effectively excited by ultraviolet, purple or blue light in the range of 250-480nm.

[0033] Example

Embodiment 2

[0035] (Ca 0.5 Mg 0.35 )(W 0.8 Mo 0.2 )O 4 :Eu 0.15 The preparation of fluorescent powder, the specific implementation process is as follows:

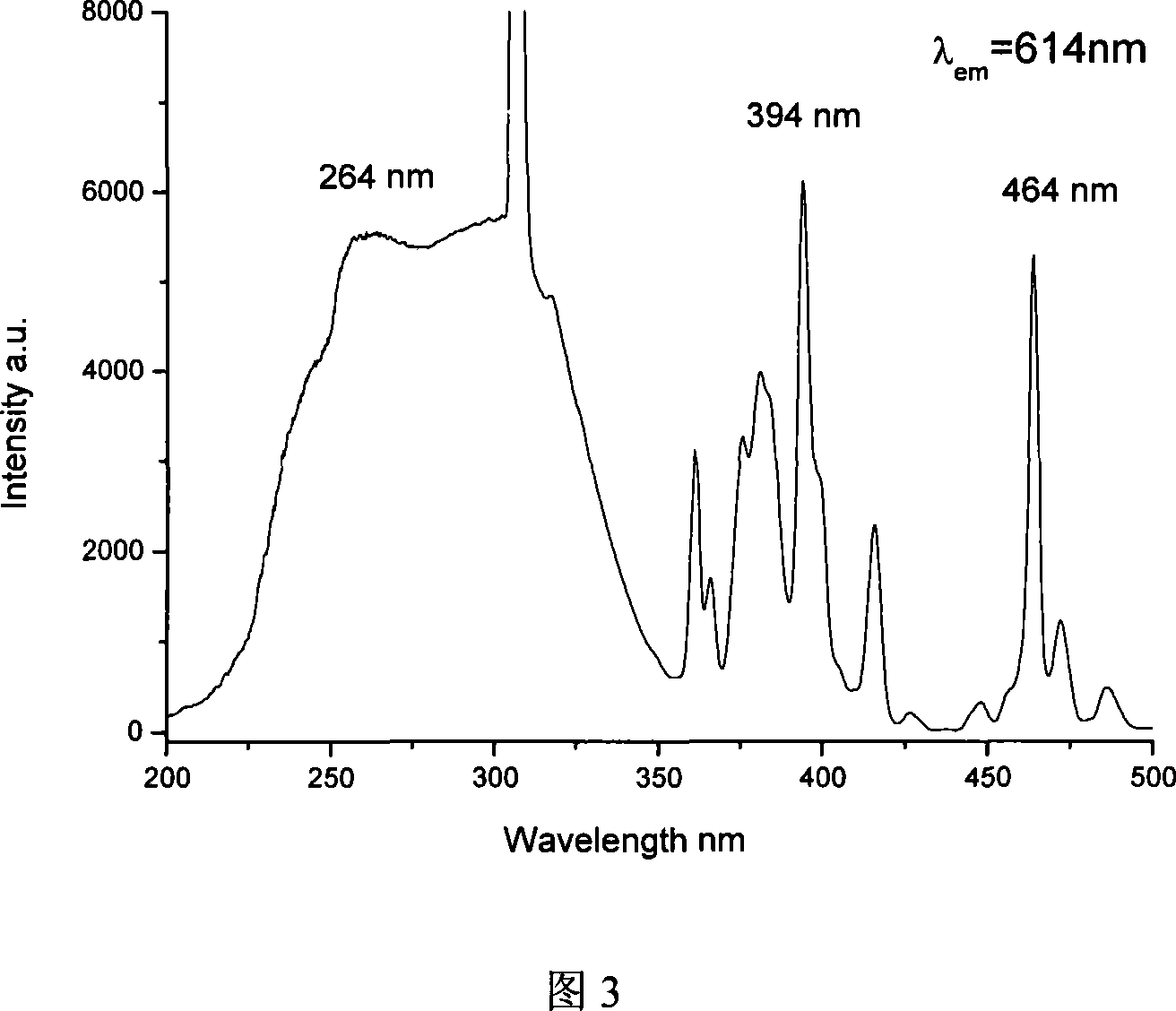

[0036] Weigh CaCO according to the molar ratio of the above stoichiometric formula 3 (AR)0.8508g, (MgCO 3 ).Mg(OH) 2 .5H 2 O(AR)0.6801g, (AR)WO 3 (AR) 3.7096g, MoO 3 (AR) 0.5758g, Eu 2 o 3 (4N)0.5282g, H 3 BO 3 (AR) 0.3172g. After the above-mentioned raw materials are fully ground and uniform, they are put into an alumina crucible and heat-treated in an air atmosphere at 1050°C for 2.5 hours. The heat-treated product is crushed, pickled to remove impurities, filtered, and dried at 100°C to obtain the chemical composition of Ca 0.85 (W 0.8 Mo 0.2 )O 4 :Eu 0.15 of red phosphor. The excitation spectrum is shown in Figure 3, the emission spectrum is shown in Figure 4, and the fluorescence data are shown in Table 1. It can be seen from the chart data that the phosphor can be effectively excited by ultraviolet, purple o...

Embodiment 3

[0038] (Ca 0.5 Sr 0.35 )(W 0.5 Mo 0.5 )O 4 :Eu 0.15 The preparation of fluorescent powder, the specific implementation process is as follows:

[0039] Weigh CaCO according to the molar ratio of the above stoichiometric formula 3 (AR) 0.8508g, SrCO 3 (AR) 1.0333g, WO 3 (AR) 2.3185g, MoO 3 (AR) 1.4394g, Eu 2 o 3 (4N)0.5282g, H 3 BO 3 (AR) 0.3085g. After the above-mentioned raw materials are fully ground and uniform, they are put into an alumina crucible and heat-treated in an air atmosphere at 1100°C for 2 hours. The heat-treated product is crushed, washed with alkali and water to remove impurities, filtered, and dried at 80°C to obtain the chemical composition of Ca 0.85 (W 0.5 Mo 0.5 )O 4 :Eu 0.15 of red phosphor. The excitation spectrum is shown in Figure 5, the emission spectrum is shown in Figure 6, and the fluorescence data are shown in Table 1. It can be seen from the chart data that the phosphor can be effectively excited by ultraviolet, purple or blu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com