Gold-extraction process for tail-one cyanide containing gold wrapped by original sulfides

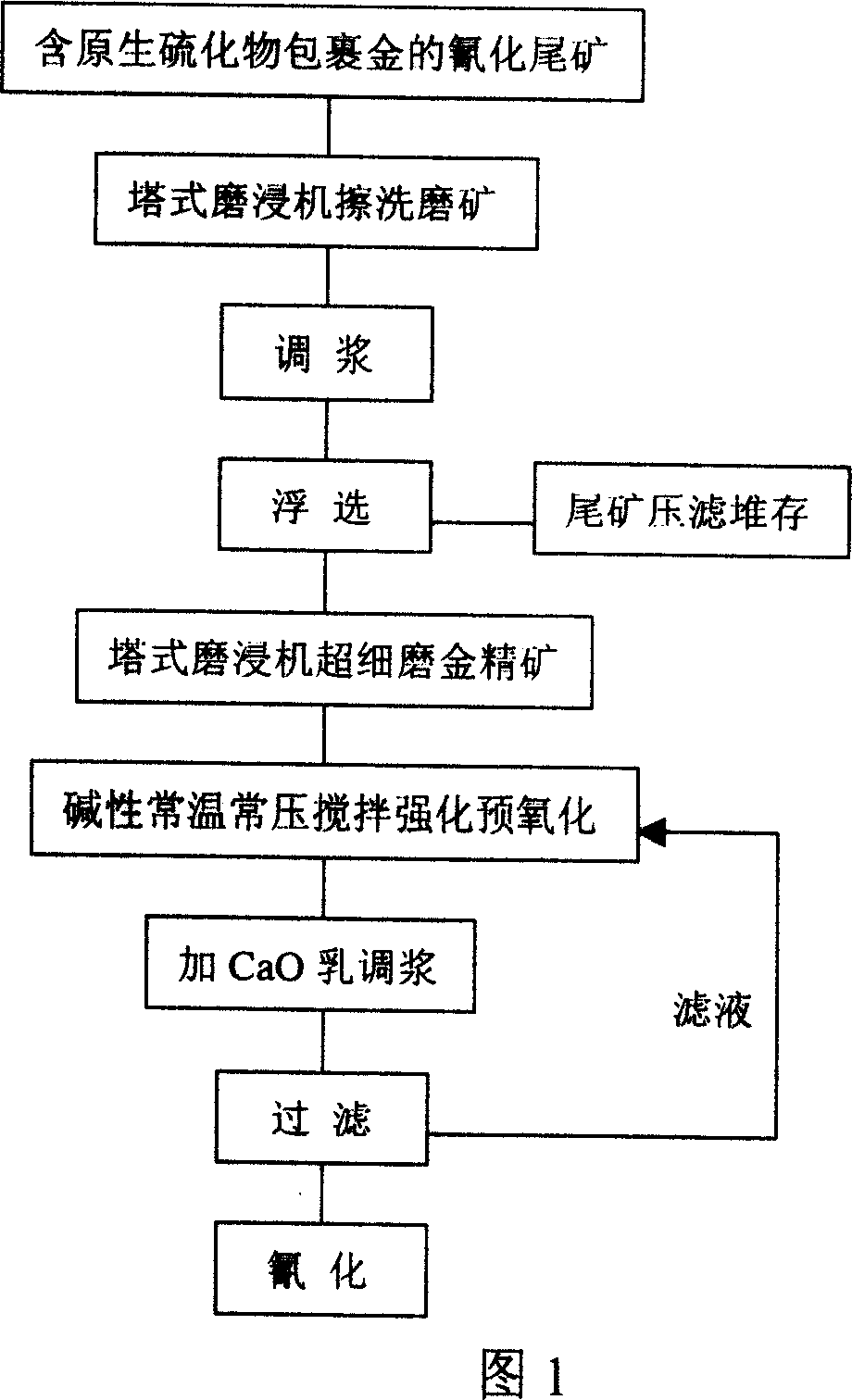

A technology for cyaniding tailings and process methods, which is applied in chemical instruments and methods, improvement of process efficiency, wet separation, etc., can solve problems such as increasing daily processing scale, low gold recovery value, unreasonable economy, etc., and achieves Good buoyancy, the effect of saving mining and grinding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

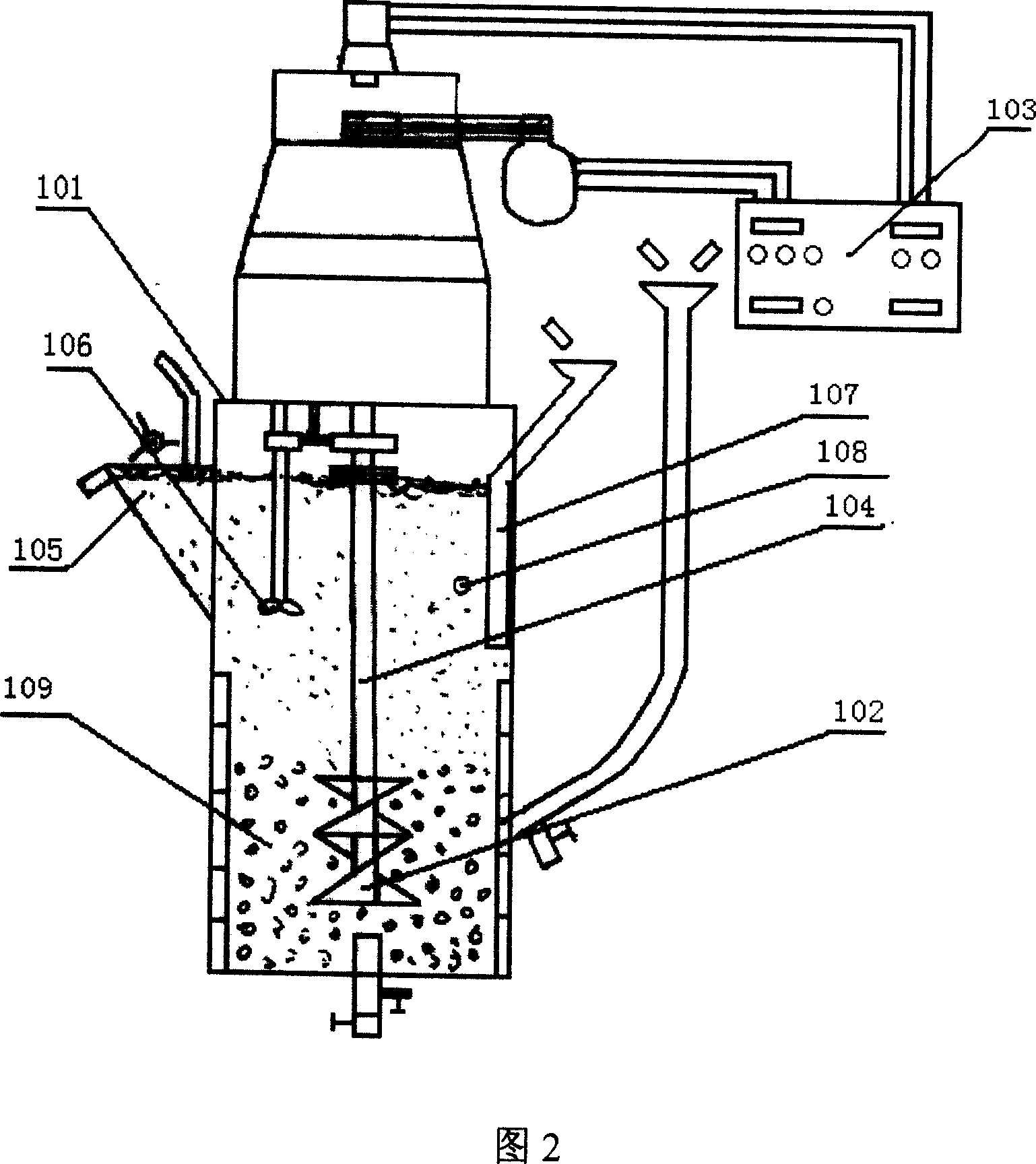

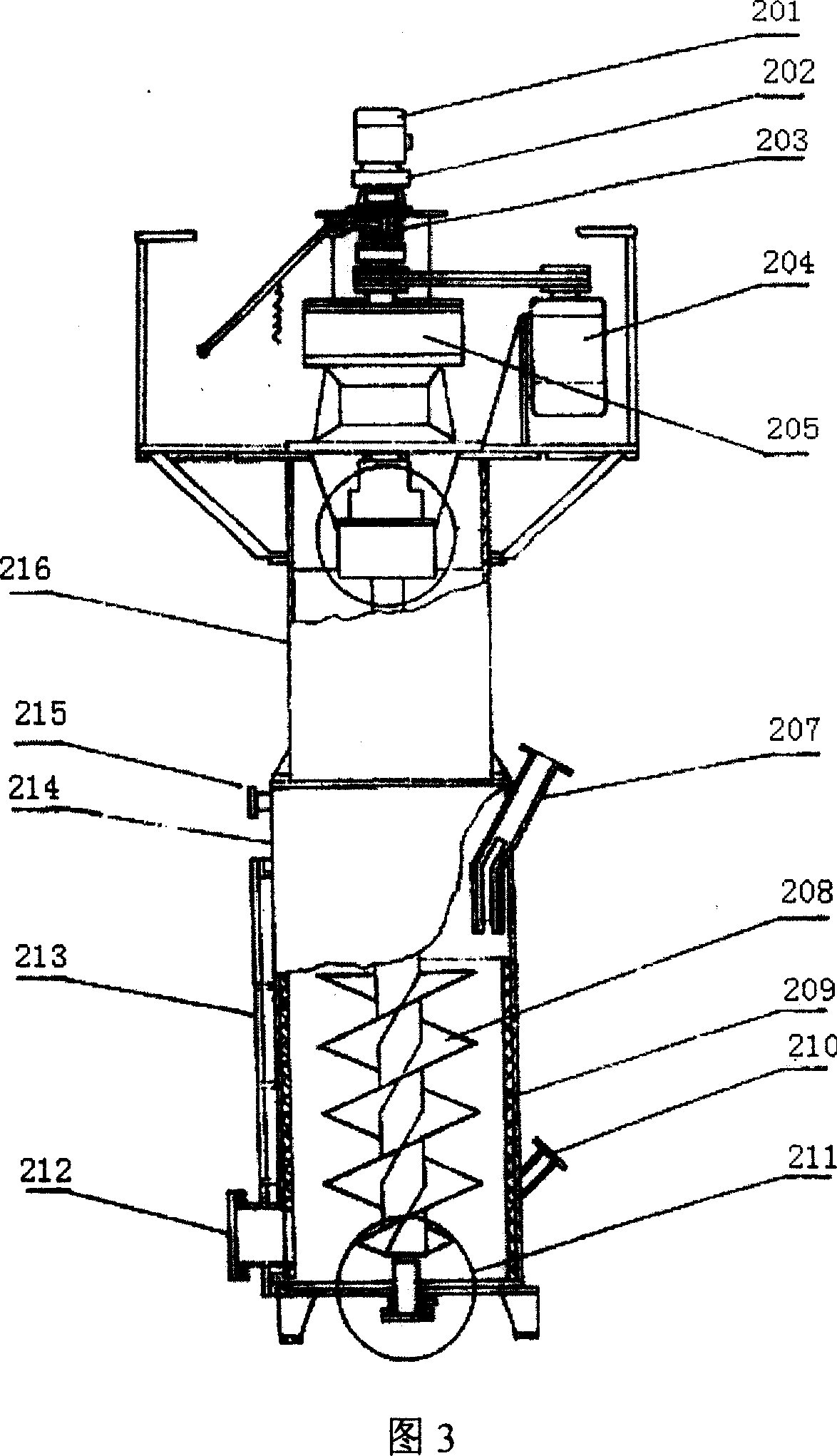

Method used

Image

Examples

Embodiment 1

[0045] A certain cyanide tailing contains Au 4.67g / t, and the content of -200 mesh is about 85%. Firstly, the cyanide tailings are adjusted to slurry and scrubbed and grind in a tower grinding and leaching machine, the ore concentration is 50%, and the ore fineness is -200 mesh accounting for 90%. Then adjust the slurry to 33% concentration and enter the flotation operation. Flotation is divided into one rough selection, one sweep selection, and two selections. For rough selection, add 240g / t copper sulfate, 16g / t butyl ammonium black medicine, 50g / t butyl xanthate, 20g / t 2# oil, and flotation time 5min. 120g / t of copper sulfate is added to the selection, and the flotation time is 3min. Add 120g / t of copper sulfate, 25g / t of butyl xanthate, 10g / t of 2# oil, and flotation time of 3min in one sweep. In the second sweep, 12g / t of butyl xanthate and 10g / t of 2# oil were selected, and the flotation time was 2min. The flotation results are as follows:

[0046] Grade of incoming alloy: 4...

Embodiment 2

[0058] A certain cyanide tailing contains Au 3.19g / t, and the content of -200 mesh is about 85%. Firstly, the cyanide tailings are adjusted to slurry and scrubbed and grind in a tower grinding and leaching machine, the ore concentration is 50%, and the ore fineness is -200 mesh accounting for 90%. Then adjust the slurry to 33% concentration and enter the flotation operation. Flotation is divided into one rough selection, one sweep selection, and two selections. Add copper sulfate 260g / t, butyl ammonium black medicine 16g / t, butyl xanthate 45g / t, 2# oil 20g / t, and flotation time 5min. 120g / t of copper sulfate is added to the selection, and the flotation time is 3min. Add 120g / t of copper sulfate, 20g / t of butyl xanthate, 10g / t of 2# oil, and floatation time of 3min in one sweep. In the second sweep, 10g / t of butyl xanthate, 10g / t of 2# oil, flotation time 2min. The flotation results are as follows:

[0059] Grade of incoming alloy: 3.19g / t;

[0060] Tailings alloy grade: 0.66g / t;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com