Vacuole corrosion resistant hardening casting

A technology of air resistance and casting, applied in the field of metallurgy, can solve the problems of long-term use and large main engine power, and achieve excellent seawater corrosion resistance and cavitation corrosion resistance, high strength, and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

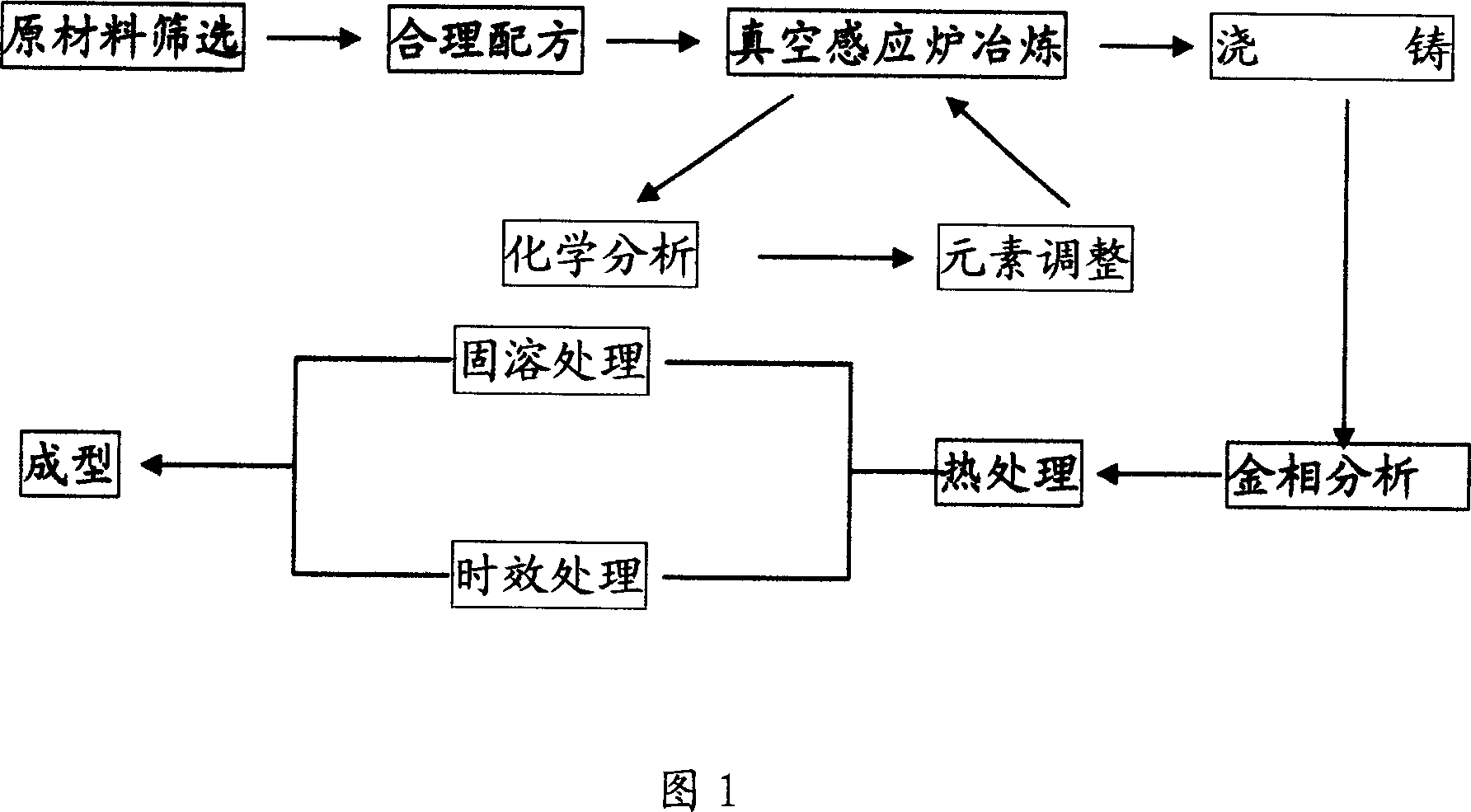

Method used

Image

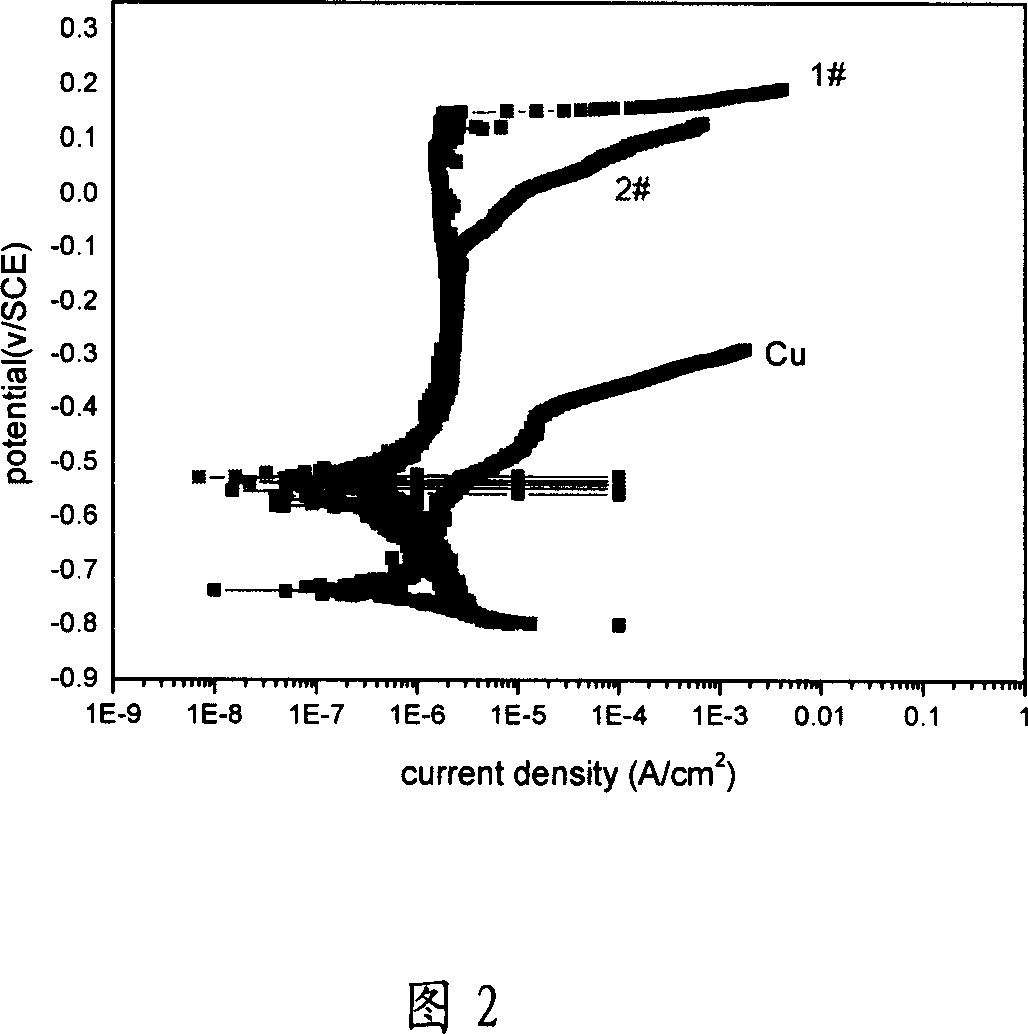

Examples

Embodiment 1

[0014] One, the composition and weight percentage of the anti-cavitation corrosion hardening casting of the present invention, specifically see the following table 1:

[0015] try

Sample

the carbon

chrome

copper

iron

1

0.10

1.5

2.5

11.0

8.5

1.5

3.5

0.2

0.15

0.08

margin

2

0.06

0.8

1.0

13.5

7.0

2.5

2.5

0.4

0.10

0.04

margin

3

0.02

0.3

0.5

12.0

5.5

2.5

2.5

0.4

0

0

margin

4

0.08

0.1

1.5

15.0

6.0

3.0

2.0

0.4

0.05

0.06

margin

5

0.04

1.0

2.0

14.0

6.5

2.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com