Bionics artificial muscle material based on electro spinning superfine fibre and method for making same

A technology of ultra-fine fibers and artificial muscles, applied in the field of artificial muscle materials, can solve problems such as slow progress, and achieve the effect of reducing contraction force and expanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

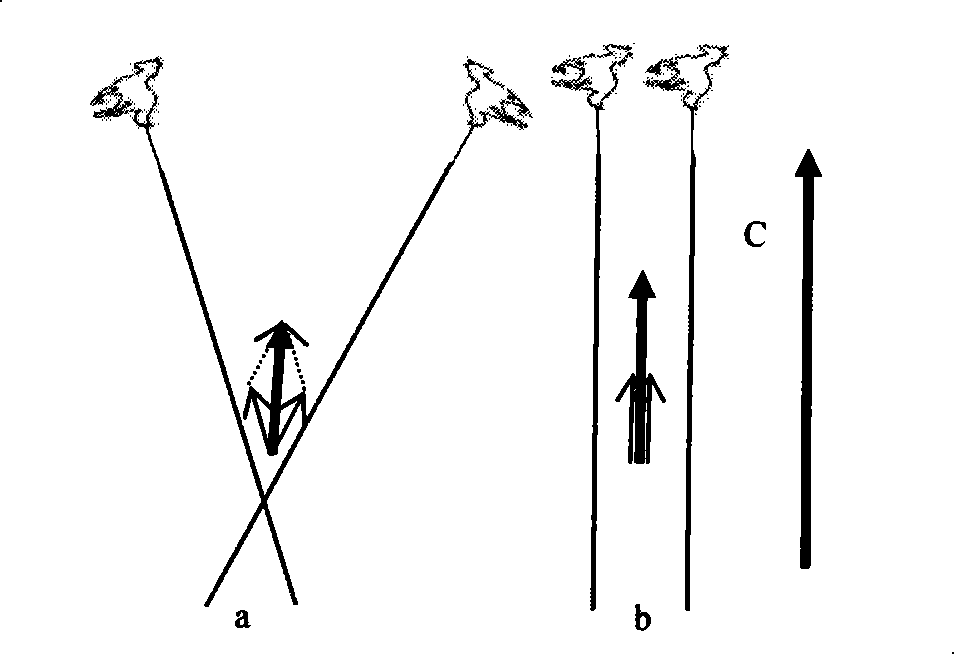

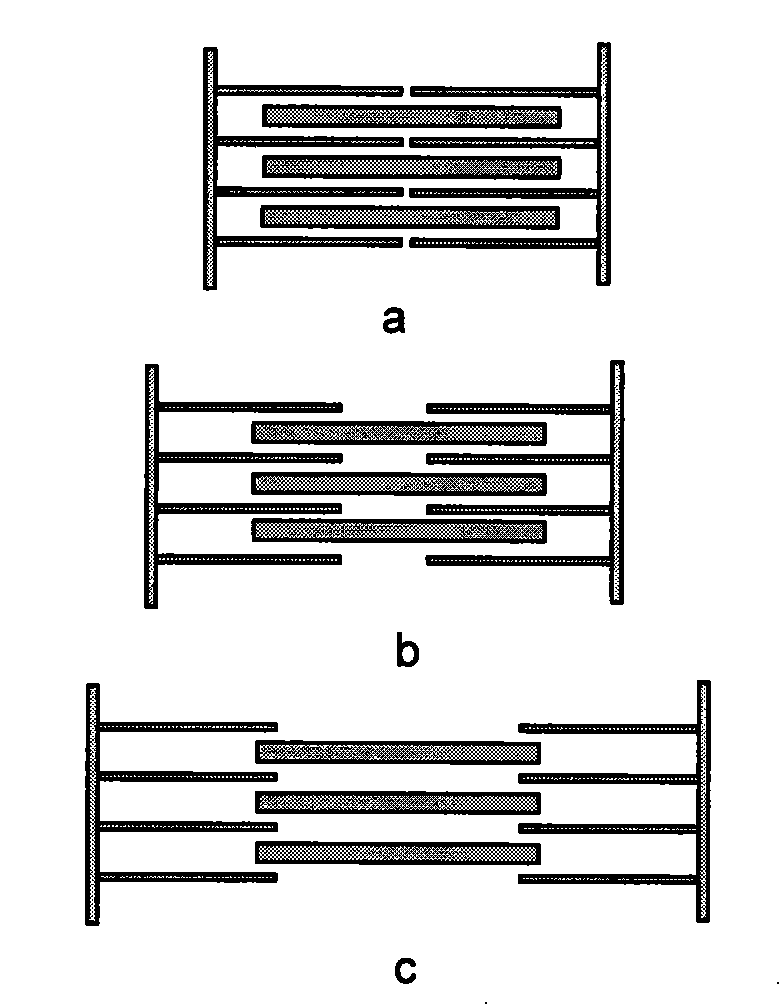

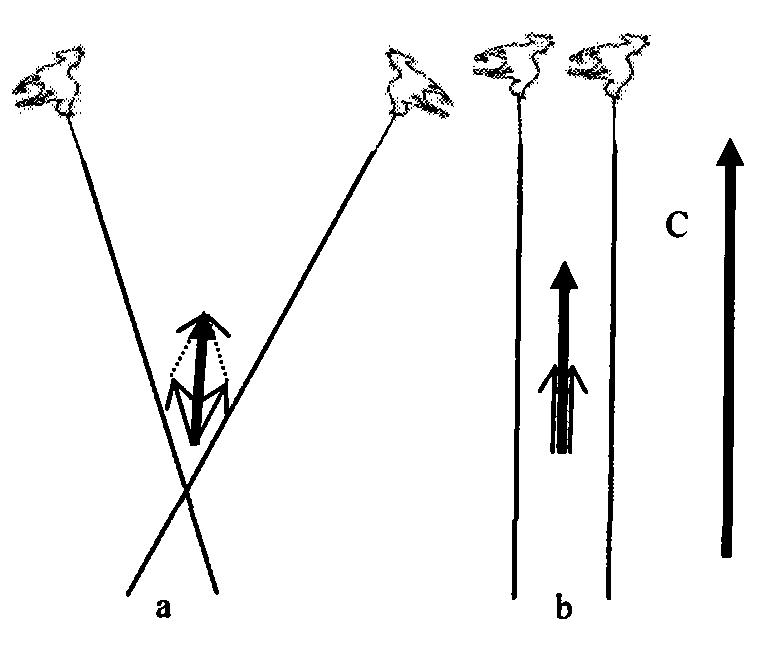

Image

Examples

Embodiment 1

[0023] A 20% polyacrylonitrile N,N-dimethylformamide solution with an average molecular weight of 80,000 was prepared. Then it was prepared into polyacrylonitrile microfibers with a size of hundreds of nanometers by electrospinning. After cross-linking at 220 degrees Celsius for 1 hour, the microfibers were treated in 1 mol / l sodium hydroxide aqueous solution at 90 degrees Celsius for 30 minutes, and finally washed and dried to obtain acid-base response composed of cross-linked polyacrylic acid. artificial muscle material. The material shrinks under acidic conditions and stretches under alkaline conditions.

Embodiment 2

[0025] A 20% polyacrylonitrile N,N-dimethylformamide solution with an average molecular weight of 80,000 was prepared. Then, the polyacrylonitrile microfibers with a size of hundreds of nanometers arranged in alignment were prepared by electrospinning by using a collection device composed of parallel iron wire arrays connected side by side with an interval of 2 mm. After cross-linking the superfine fibers at 220 degrees Celsius for 1 hour, treat them in 1mol / l sodium hydroxide aqueous solution at 90 degrees Celsius for 30 minutes, and finally wash and dry them to obtain cross-linked polyacrylic acid superfine fibers with orientation alignment. Acid-base responsive artificial muscle material. The material can shrink or stretch by controlling acid and alkali conditions.

Embodiment 3

[0027]A N,N-dimethylformamide solution of polyacrylonitrile with an average molecular weight of 80,000 with a mass concentration of 20% and carbon nanotubes with a mass concentration of 1% was prepared. Then, polyacrylonitrile microfibers with a size of hundreds of nanometers arranged in alignment were prepared by electrospinning. After cross-linking at 220 degrees Celsius for 1 hour, the ultra-fine fibers are treated in 1 mol / l sodium hydroxide aqueous solution at 90 degrees Celsius for 30 minutes, and finally cleaned and dried to obtain carbon nanotubes with improved strength and alignment. Acid-base responsive artificial muscle material composed of cross-linked polyacrylic acid microfibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com