Method for improving cleanliness of electron chemicals

An electronic chemical and cleanliness technology, applied in the field of electronic chemicals, can solve the problems of high-purity, clean solid chemical purification methods that have not been reported and researched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh the polyethyleneimine and separate it, select 200g of polyethyleneimine with n equal to 6-20, 1000ml of 15% sodium hydroxide, put it into the reaction bottle at 15°C, add 400g of carbon disulfide dropwise, and stir for 40 minutes to precipitate a solid. Filter, wash with deionized water and drain to obtain a solid product. The product was analyzed by infrared spectroscopy to be sodium polythiocarbamate.

Embodiment 2

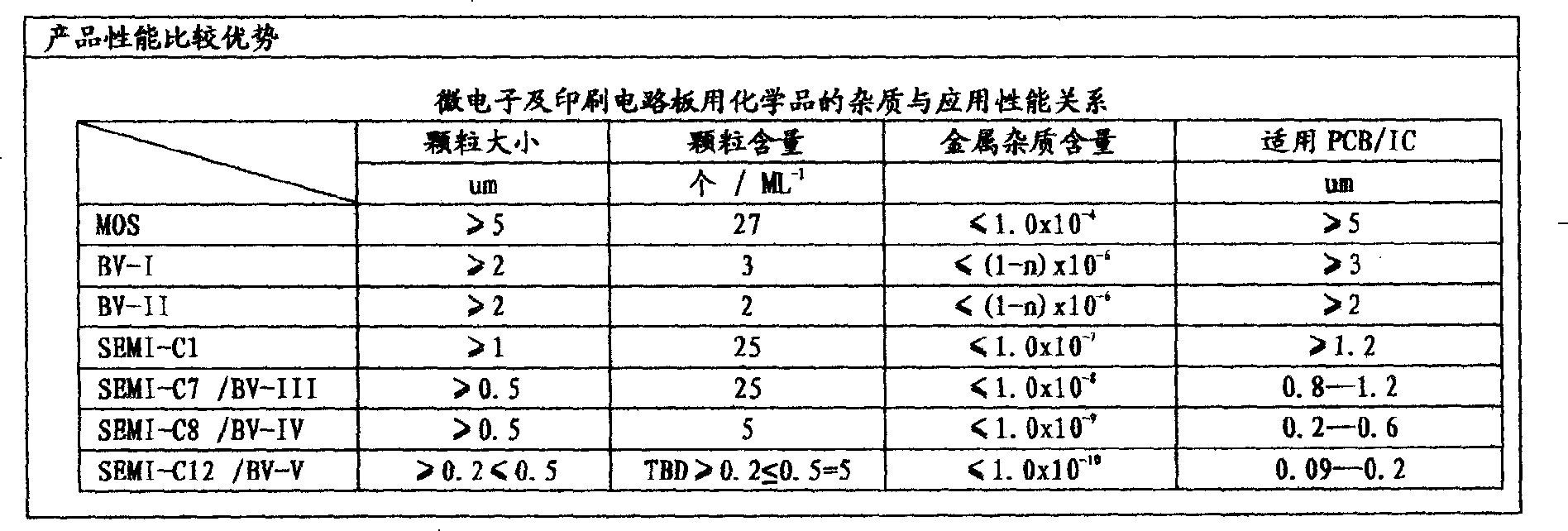

[0024] Weigh 100 g of 2,3,4-trihydroxybenzophenone (the sum of the metal ion content is 200 mg / g), add 300 ml of acetone to dissolve, add 0.1 g of chelating agent sodium polythiocarbamate, stir at room temperature for 3 hours, and collect in the solution The various metal ions that exist form chelate precipitates, which are filtered through a primary or secondary ultra-microfiltration device, and the micro-filtration is completed under a pressure of 0.1-0.3 MPa or under vacuum to remove particles larger than 0.2un at the same time. The precipitate was removed, and the resulting solution was evaporated, cooled, and separated to obtain the product. After testing: copper, lead, zinc, manganese, magnesium, iron and other metal ions impurity content: ≤1.0×10 -10 , Non-metal impurity particles (≥0.2um, ≤0.5um) are ≤5 / mL.

Embodiment 3

[0026] Weigh 500g of 4'-chloro-3,4-dihydroxybenzophenone (total metal ion content 416.1mg / g), add 1500ml of toluene and heat up to dissolve it, add 3g of sodium polythiocarbamate, stir for 5 hours, and collect Various metal ions in the solution form chelate precipitates, and microfiltration is completed under 0.3MPa vacuum to remove particles larger than 0.2un at the same time. The precipitate was removed, and the resulting solution was evaporated, cooled, and separated to obtain the product. After testing: copper, lead, zinc, manganese, magnesium, iron and other metal ions impurity content: ≤1.0×10 -10 ; Non-metal impurity particles (≥0.2um, ≤0.5um) are ≤5 / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com