Method for making flexibility temperature sensor

A technology of temperature sensor and manufacturing method, which is applied to thermometers, thermometers and instruments using electric/magnetic elements that are directly sensitive to heat, and can solve the problem of affecting the performance of flexible devices and the integrity of their structures, and the easy displacement of PI films , reduce device yield and other issues, achieve good thermal isolation performance, light and thin structure, and improve the effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

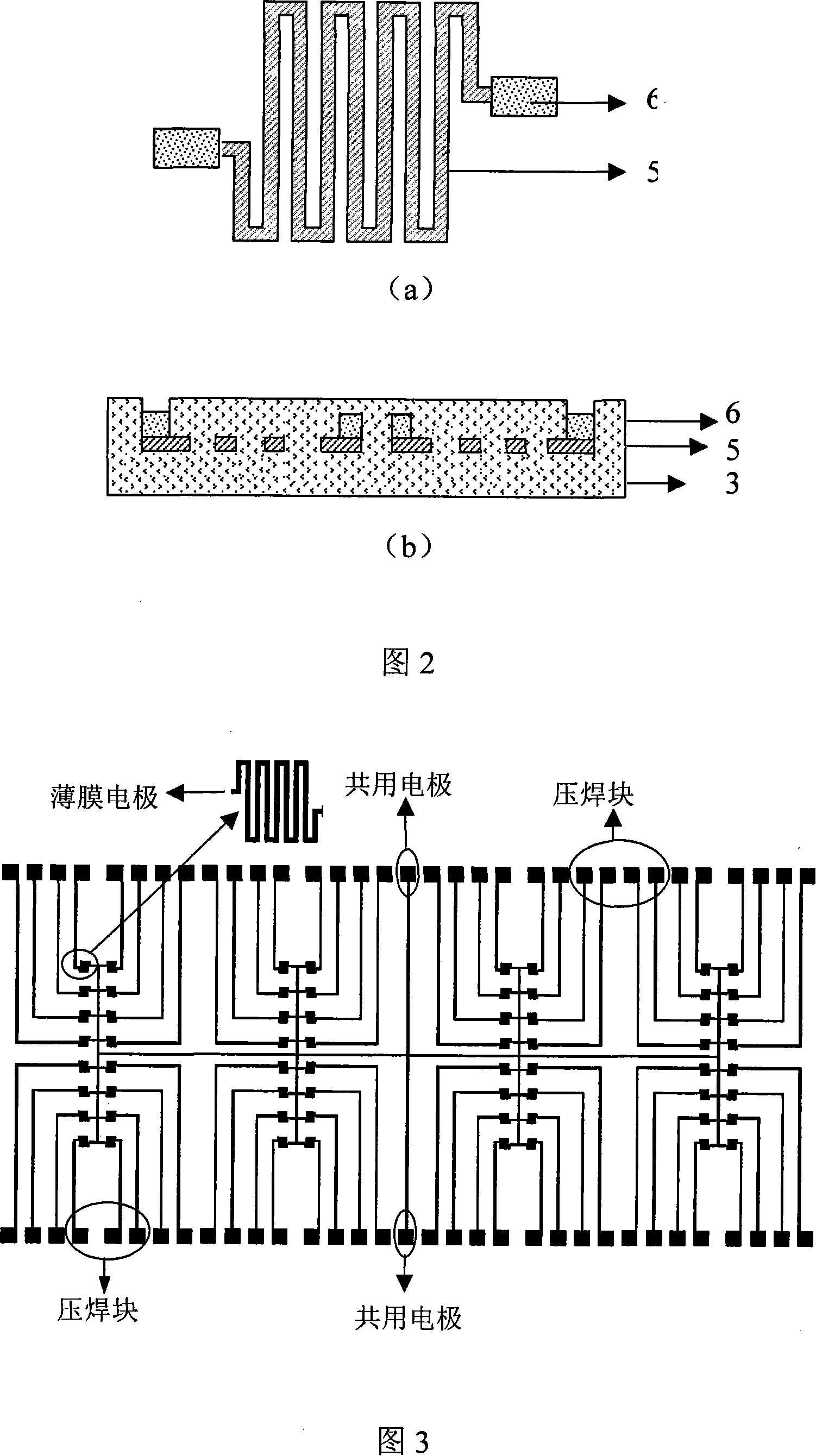

[0041] An implementation example is specifically introduced below to further illustrate that the method of the present invention is also suitable for the manufacture of a sensor array composed of many such flexible temperature sensor units.

[0042] Referring to Figure 3, 64 temperature-sensitive units are arranged in an 8×8 array structure: the area of the entire array is 2500×5500 μm 2 , the sensitive unit in the array is in the shape of a snake, the unit size line length × line width × line thickness is 644 μm × 4 μm × 0.12 μm, and the area size is 68 × 68 μm 2 .

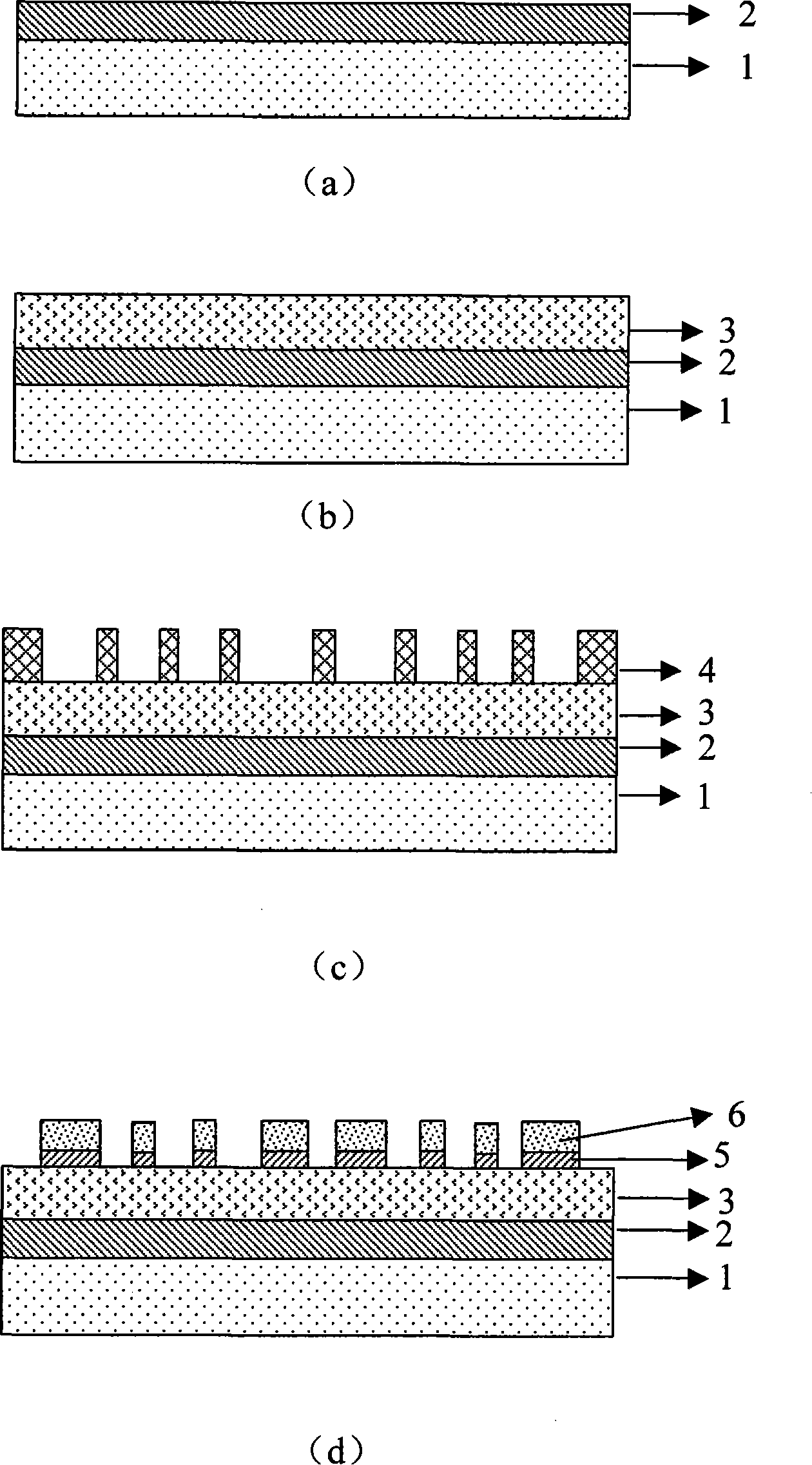

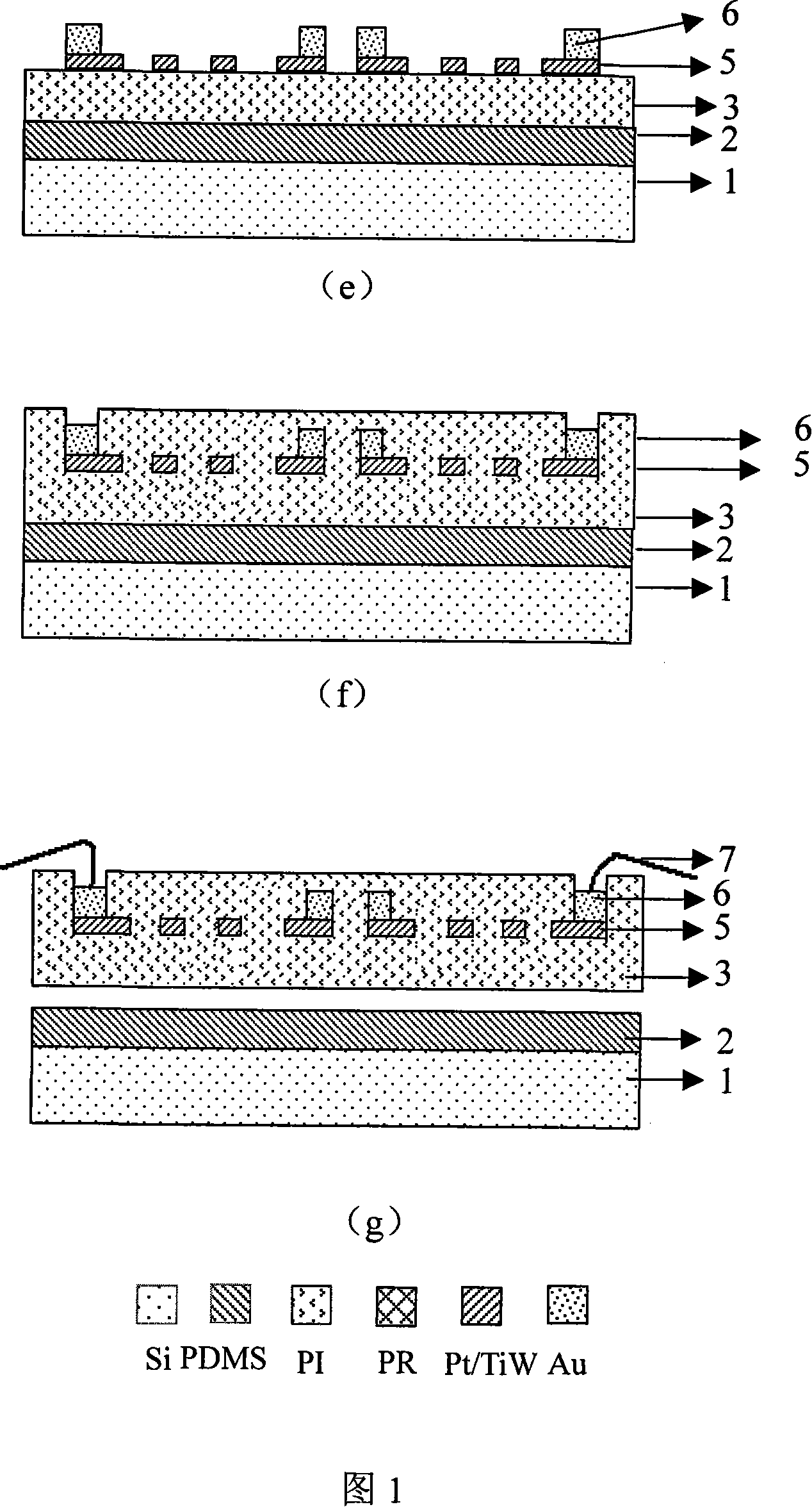

[0043] Manufactured according to the manufacturing method of the flexible MEMS temperature sensor described in the present invention. In the process of device processing, ordinary single-polished silicon wafers are used as the carrier to provide a flat processing surface. First, a layer of 50 μm PDMS interlayer is coated on the mechanically processed carrier silicon wafer to help the separation of flexible dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com