Linear servo control bar-crossing system of warp knitting machine

A bar traverse, servo control technology, applied in warp knitting, comprehensive factory control, comprehensive factory control, etc., can solve the lack of production management data and fault diagnosis network, the production speed limit of warp knitting machine, man-machine dialogue Not friendly enough, etc., to achieve the effect of strong self-detection ability, fast pattern design, saving storage and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

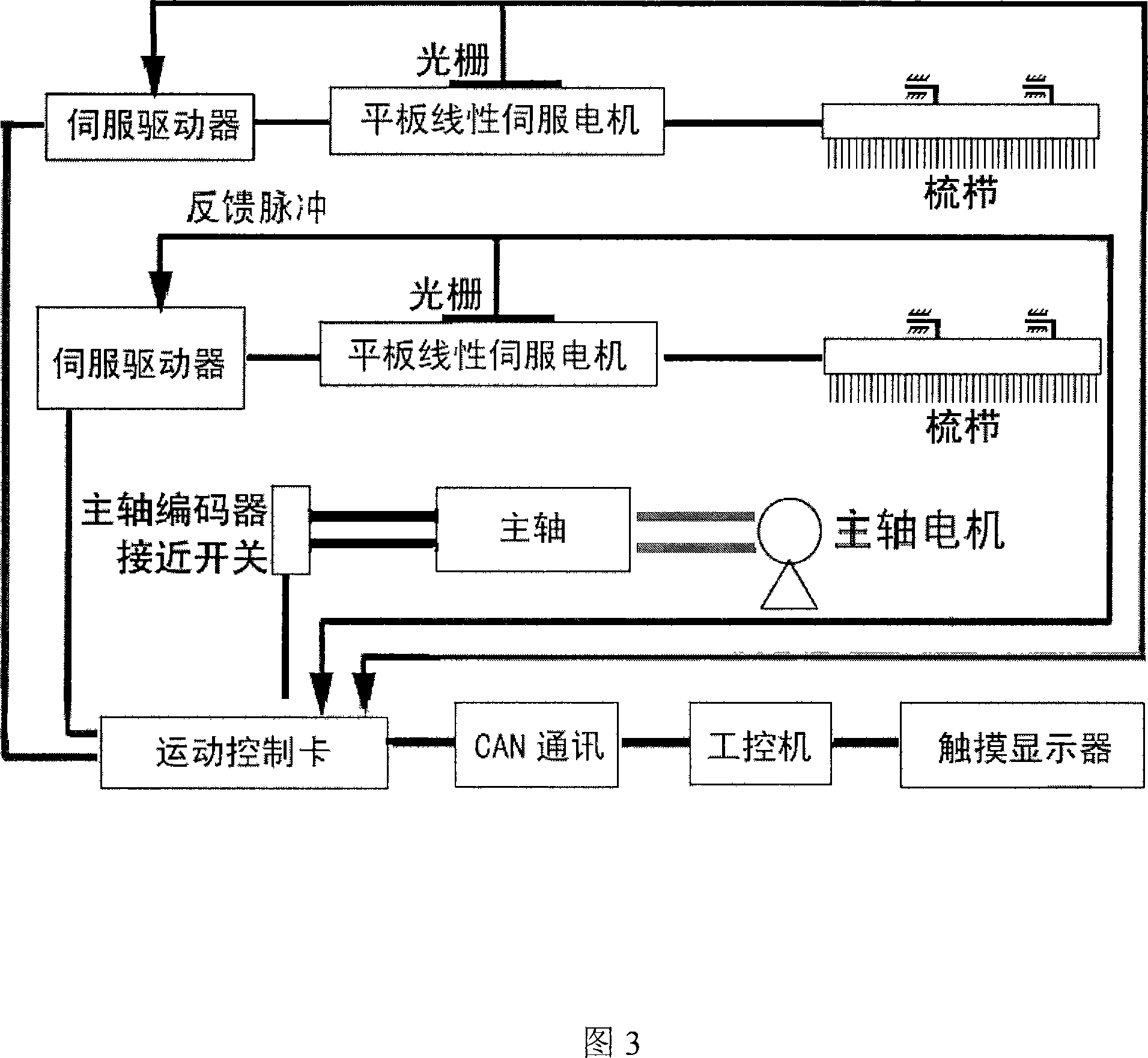

[0017] In Figure 2, 1 is the bar of the warp knitting machine, 2 is the strut, 3 is the tension steel wire and spring, 4 is the limit proximity switch, 5 is the cylindrical linear servo motor shaft (mover), and 6 is the kinematic connection Rod, 7 is a guide rod for combing bar traverse, 8 is a grating, 9 is a cylindrical linear servo motor, and 10 is a warp knitting machine frame (i.e. a traverse mechanism installation base).

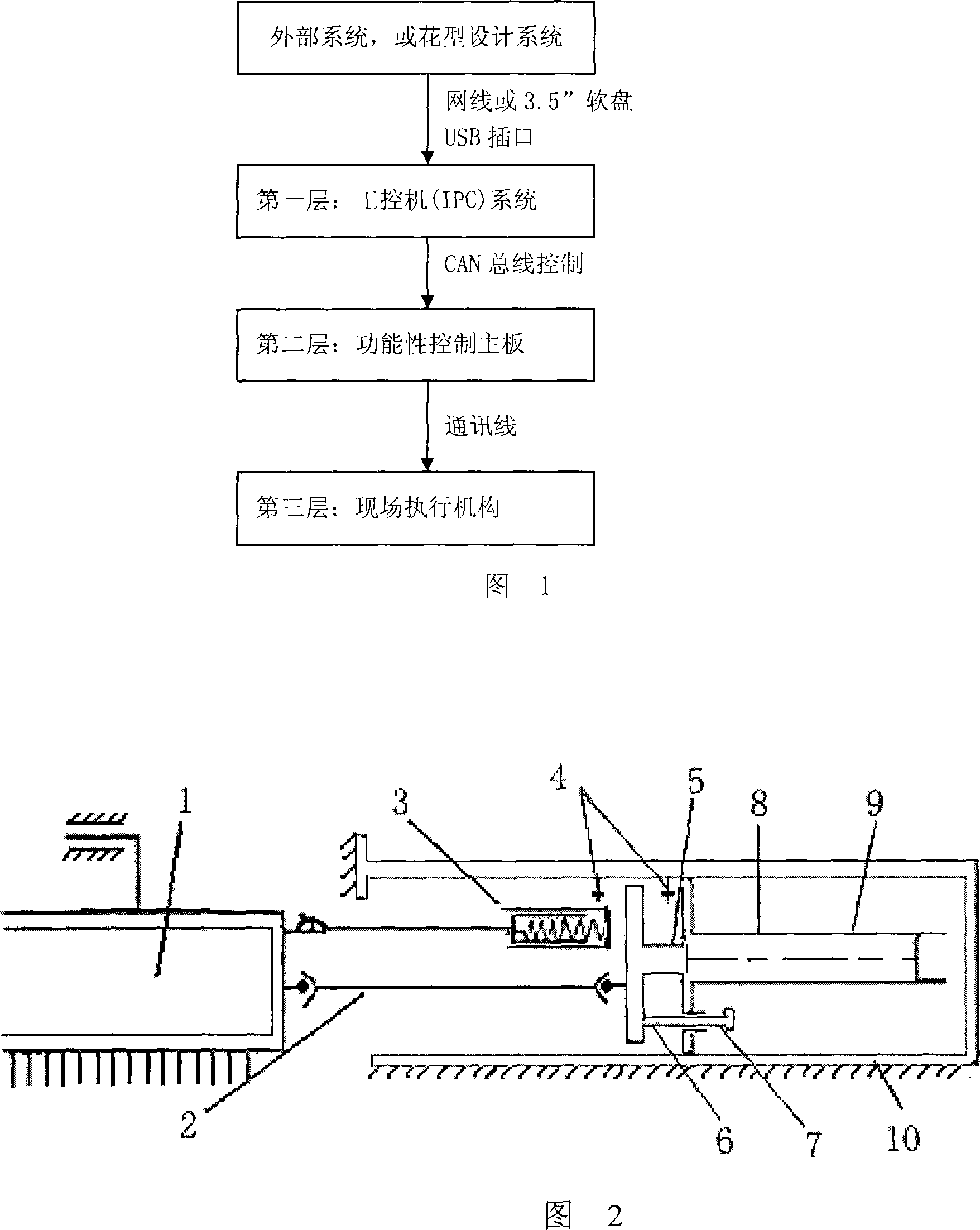

[0018] The present invention adopts fieldbus technology, and the system architecture is a three-level network distributed control system based on CAN bus, wherein:

[0019] The first level is the management team, and the central controller is an industrial computer (that is, an industrial control computer), which is used for pattern input, production control, pattern data verification and network communication;

[0020] The second level is the control layer, which is composed of an embedded microcontroller to form a separate independent control unit, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com