Process of preparing plate porous membrane with high permeating flux

A high-permeability, flat-plate membrane technology, applied in the field of membrane separation, to achieve the effect of high penetration of membrane pores, high porosity, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

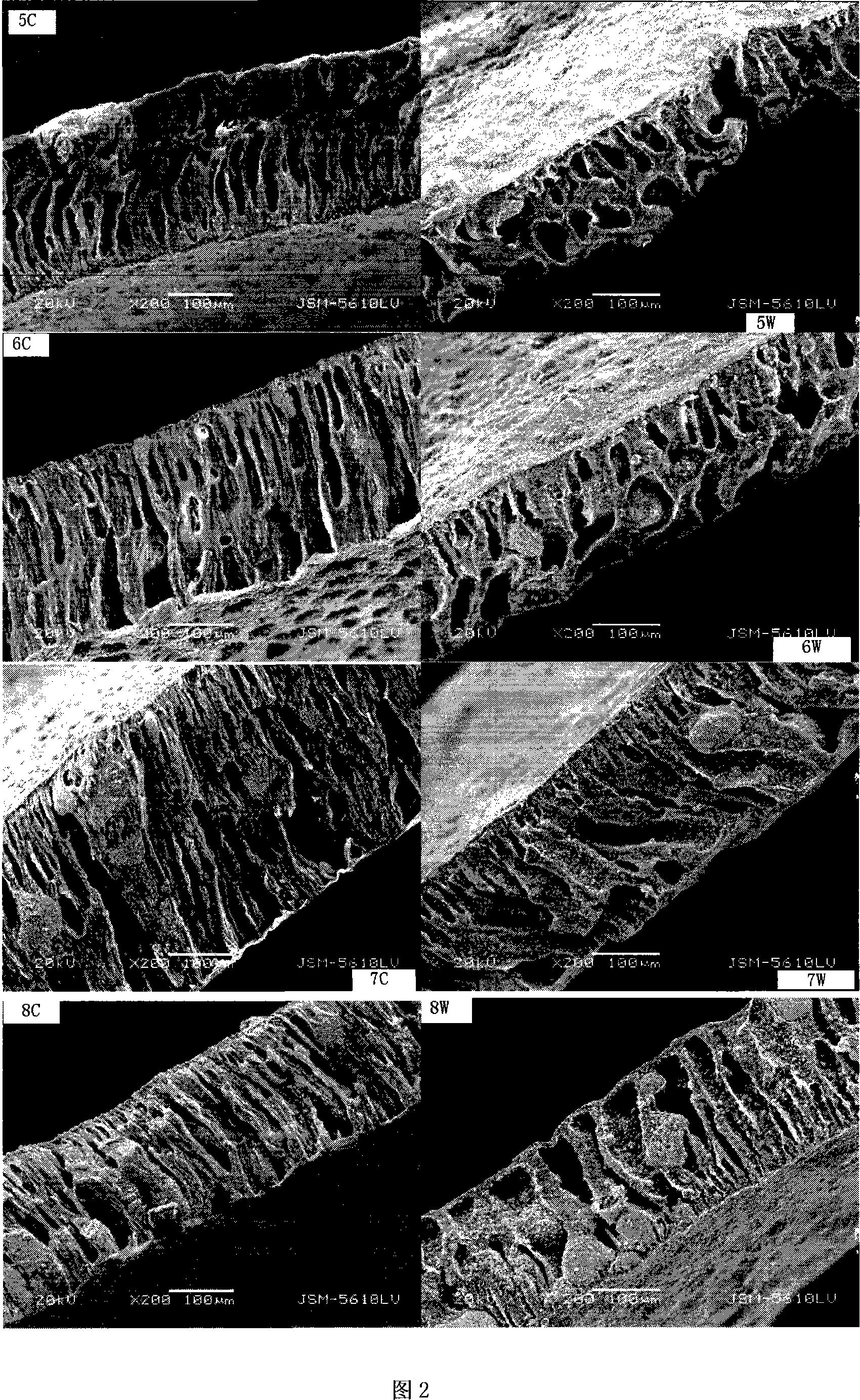

[0032] Embodiment 1: polyacrylonitrile / Fe 3 o 4 Preparation of porous membrane

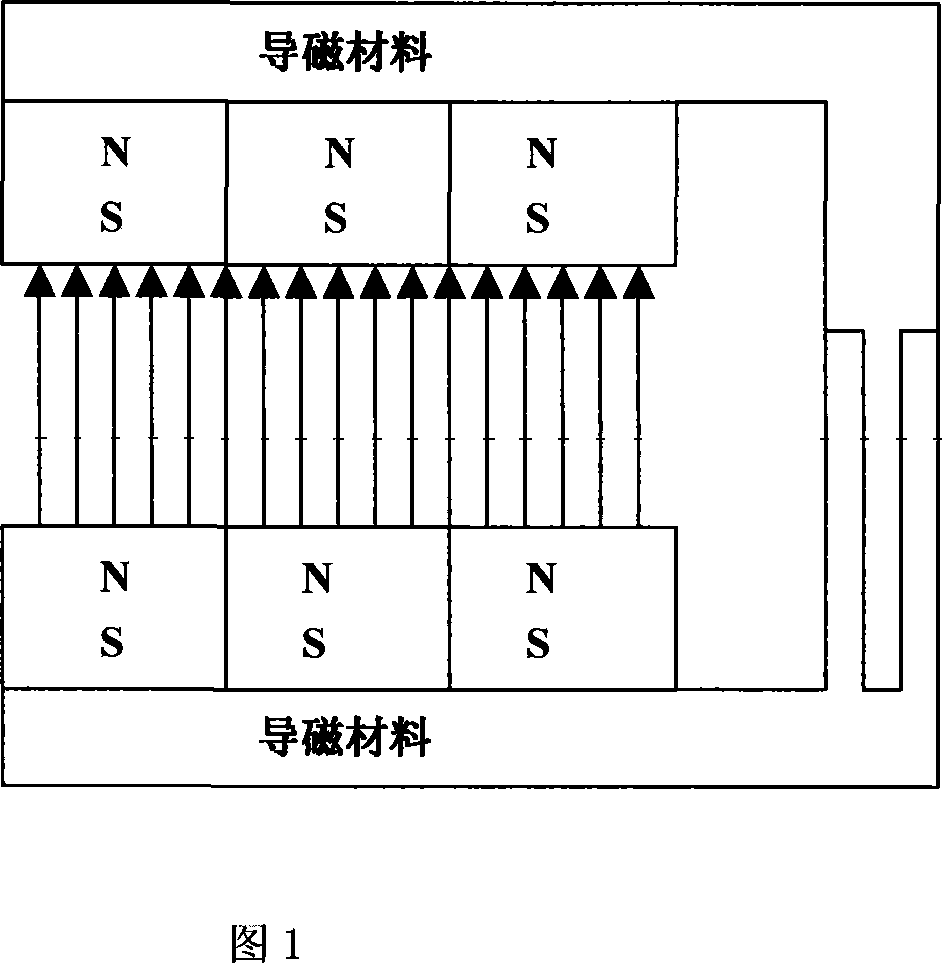

[0033] See Figure 1. The orthogonal magnetic field can be prepared by two or more permanent magnets and magnetically permeable materials. The number of magnets is determined according to the area of the film; the strength of the magnetic field can be controlled by the distance between the upper and lower magnets and the position of the film in the magnetic field. , the greater the distance between the upper and lower magnets, the smaller the magnetic field intensity; when the membrane is in the middle of the magnetic field, the magnetic field intensity is smaller, and the closer the distance between the membrane and the upper and lower magnets, the greater the magnetic field intensity.

[0034] Take 100ml of dimethyl sulfoxide (DMSO) and place them in 5 iodine measuring bottles, respectively add 3.9g of polyvinylpyrrolidone (PVP) therein, and wait for it to fully dissolve; weigh 57.6g, 33.6g, ...

Embodiment 2

[0039] Get 100ml of dimethylacetamide (DMAC) and place it in an iodine measuring bottle, add 5.0g of polyvinylpyrrolidone (PVP) to it respectively, and wait for it to fully dissolve; weigh 12.0g of ferric oxide (Fe 3 o 4 ) mixed with 20.0 g of polysulfone and added to the above-mentioned iodine flask, shaken up quickly, shaken at 55-60°C to dissolve evenly, and defoamed. Scrape the film on a glass plate, evaporate in air (humidity less than 50%, temperature 20°C) for 5 seconds, put it in an orthogonal magnetic field (magnetic field strength 1800 gauss) and continue to evaporate for 25 seconds, add water under the action of the magnetic field to gel for 15 minutes Finally, take out the membrane and soak it in distilled water for 24 hours to obtain a magnetized membrane, and its pure water permeation flux is measured to be 1300L.m -2 .h -1 (25°C, 0.1MPa), the retention rate of bovine serum albumin is 43.9%; while scraping the film on a glass plate, evaporate it in the air (hum...

Embodiment 3

[0041] Take 100ml of N-methylpyrrolidone, 2.0g of polyethylene glycol and 16.0g of pentapentyl metal organic polymer ferromagnetic particles, heat and dissolve them at 198°C, cool to 70°C, add 10.0ml of formic acid and 1.0g of polyethersulfone, mix After homogenization, stir at 60°C to completely dissolve and homogenize, then defoam. Scrape the film on the polyester non-woven fabric, evaporate it in the air (humidity less than 50%, temperature 20°C) for 5s, put it in an orthogonal magnetic field (magnetic field strength 10000 gauss) and continue to evaporate for 25s, put it under the action of the magnetic field After gelling in a water bath for 15 minutes, take out the membrane and soak it in distilled water for 24 hours to obtain a magnetized membrane, and the measured pure water permeation flux is 730L.m -2 .h -1 (25°C, 0.1MPa), the rejection rate of bovine serum albumin is 90.9%; while scraping the film on the polyester non-woven fabric, evaporate it in the air (humidity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water permeation flux | aaaaa | aaaaa |

| Pure water permeation flux | aaaaa | aaaaa |

| Pure water permeation flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com