Process of treating oil-containing sludge

A treatment process and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, sludge treatment through temperature control, etc., can solve the problems of difficult operation, low oil recovery rate, high cost, etc., and achieve Reduce environmental pollution, efficient recycling, no pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

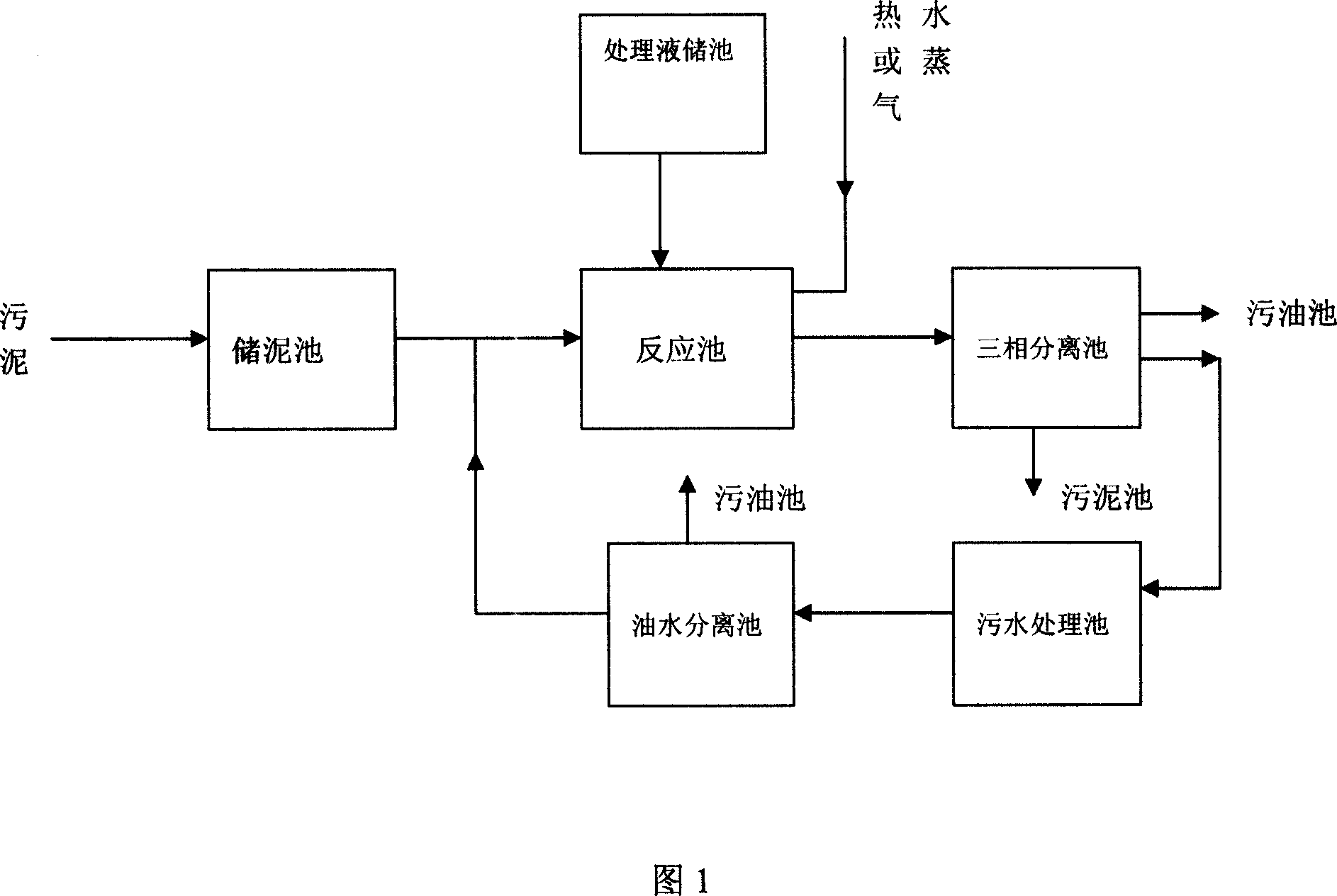

Method used

Image

Examples

Embodiment 1

[0032] The bottom mud of a large tank of an oilfield joint station was taken, and the composition of the bottom mud is shown in Table 1. Pump the oily sludge into the sludge reaction tank, add water while stirring, add water with a water / mud weight ratio of 1.5:1 to the sludge, and then add 30000ppm of treatment solution. The composition of the treatment solution is shown in Table 2 . After completing the above process of the task, heat it up to 50°C with steam and stir it with a stirrer for 2 hours. The sludge and the mud-water mixing system of the treatment liquid are fully mixed, and the crude oil in the sludge is eluted, and then gravity separation is carried out. The separation time is 12 hours; after the above process is completed, the oil and cement are collected separately; the collected oily sewage is added with 200 mg / l polyaluminium chloride, and after 15 minutes of reaction, 2 ppm of PAM is added, and then the cyclone reactor is used for solid-liquid separation. T...

Embodiment 2

[0038] Take the bottom sludge from a large tank of an oil refinery. The composition of the bottom sludge is shown in Table 3. The ratio of water / mud was added to the sludge: 1.6:1 water and 30000ppm treatment liquid, the composition of the treatment liquid is shown in Table 4. After completing the above process of the task, put in steam to heat to 50°C and stir with a stirrer for 2 hours, then carry out gravity separation, the separation time is 12 hours; after completing the above process, collect oil and cement separately; add 200mg of oily sewage to the / l of polyferric sulfate, add 2ppm of PAM after 15 minutes of reaction, and then use a gravity settling tank for solid-liquid separation. The hydraulic retention time of the reactor is 2 minutes, and the treated sewage is reused. The sludge and Dirty oil is collected separately. The concentration of crude oil in the treated sludge is less than 0.5wt%.

[0039] Table 3. Composition of tank bottom mud

[0040] samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com