Method for preparing Nano structure and thin film of molybdenum trioxide by using infrared sintering furnace

A technology of molybdenum trioxide and nanostructure, which is applied in nanostructure manufacturing, molybdenum oxide/molybdenum hydroxide, nanotechnology, etc., can solve the problems of low yield, complex preparation process, and restricted application, and achieve high yield and preparation The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

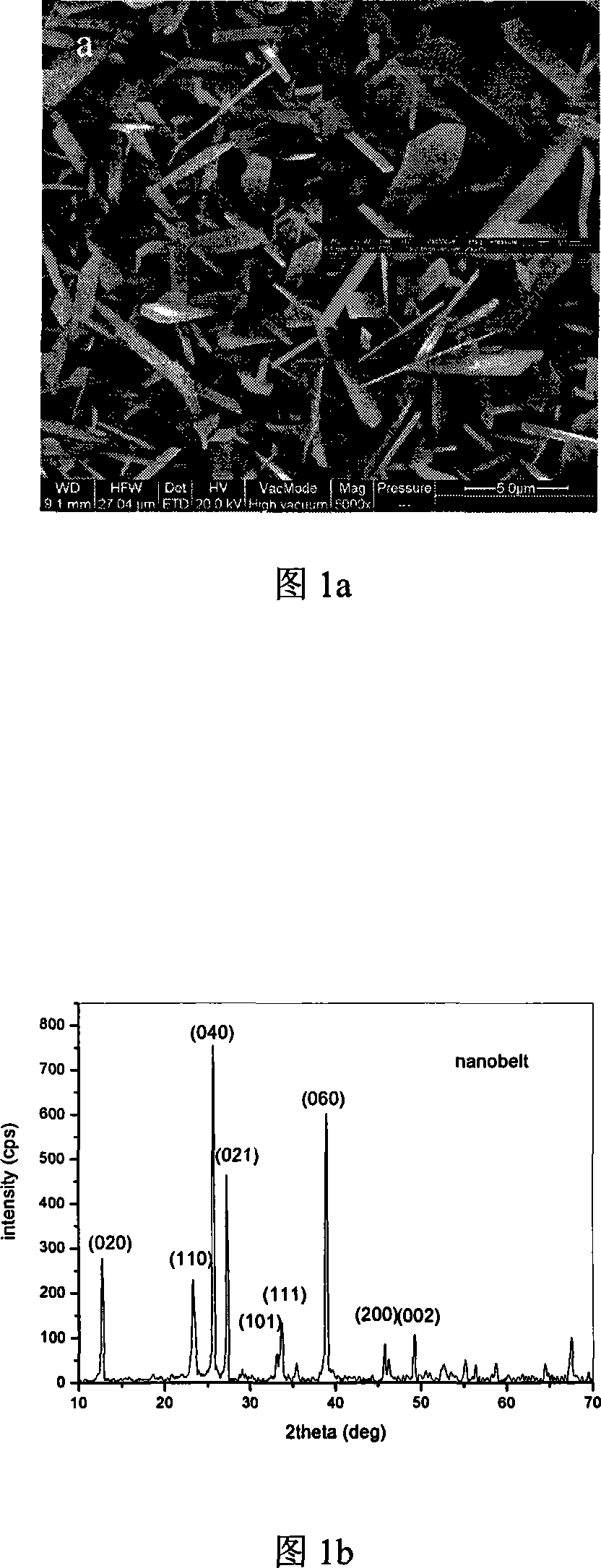

[0035] Molybdenum trioxide nanorods and thin films prepared on ITO glass

[0036] 1. Use ITO glass as the substrate, and ultrasonically clean it in acetone and absolute ethanol respectively;

[0037] 2. Start the sintering furnace device, so that the temperature of the evaporation source area rises to 650 ° C ~ 850 ° C, and the temperature of the substrate area is 150 ° C ~ 450 ° C, and keep it stable;

[0038] 3. When the temperature reaches the set temperature and starts to stabilize, transport the quartz boat loaded with molybdenum powder and ITO glass to the designated temperature zone;

[0039] 4. Keep warm for more than 1 minute;

[0040] 5. Cut off the heating source, so that the system enters the natural slow cooling process. After cooling to room temperature, take out the quartz boat and ITO glass, it can be observed that off-white substances are generated on the ITO glass substrate.

Embodiment 2

[0042] Preparation of molybdenum trioxide nanorods and thin films on glass

[0043] 1. Select ordinary glass as the substrate, and ultrasonically clean it in acetone and absolute ethanol respectively;

[0044] 2. Start the sintering furnace device, so that the temperature of the evaporation source area rises to 650 ° C ~ 850 ° C, and the temperature of the substrate area is 150 ° C ~ 450 ° C, and keep it stable;

[0045] 3. When the temperature reaches the set temperature and starts to stabilize, transport the quartz boat loaded with molybdenum powder and ordinary glass substrate to the designated temperature zone;

[0046] 4. Keep warm for more than 20 minutes;

[0047] 5. Cut off the heating source, so that the system enters the natural slow cooling process. After cooling to room temperature, take out the quartz boat and the glass substrate, and it can be observed that off-white substances are generated on the glass substrate.

Embodiment 3

[0049] Molybdenum trioxide nanosheets and thin films prepared on ITO glass

[0050] 1. Use ITO glass as the substrate, and ultrasonically clean it in acetone and absolute ethanol respectively;

[0051] 2. Start the sintering furnace device, so that the temperature of the evaporation source area rises to 650 ℃ ~ 950 ℃, and the temperature of the substrate area is from room temperature to 150 ℃, and remains stable;

[0052] 3. When the temperature reaches the set temperature and starts to stabilize, transport the quartz boat loaded with molybdenum powder and ITO glass to the designated temperature zone;

[0053] 4. Keep warm for more than 1 minute;

[0054] 5. Cut off the heating source, so that the system enters the natural slow cooling process. After cooling to room temperature, take out the quartz boat and ITO glass, it can be observed that off-white substances are generated on the ITO glass substrate.

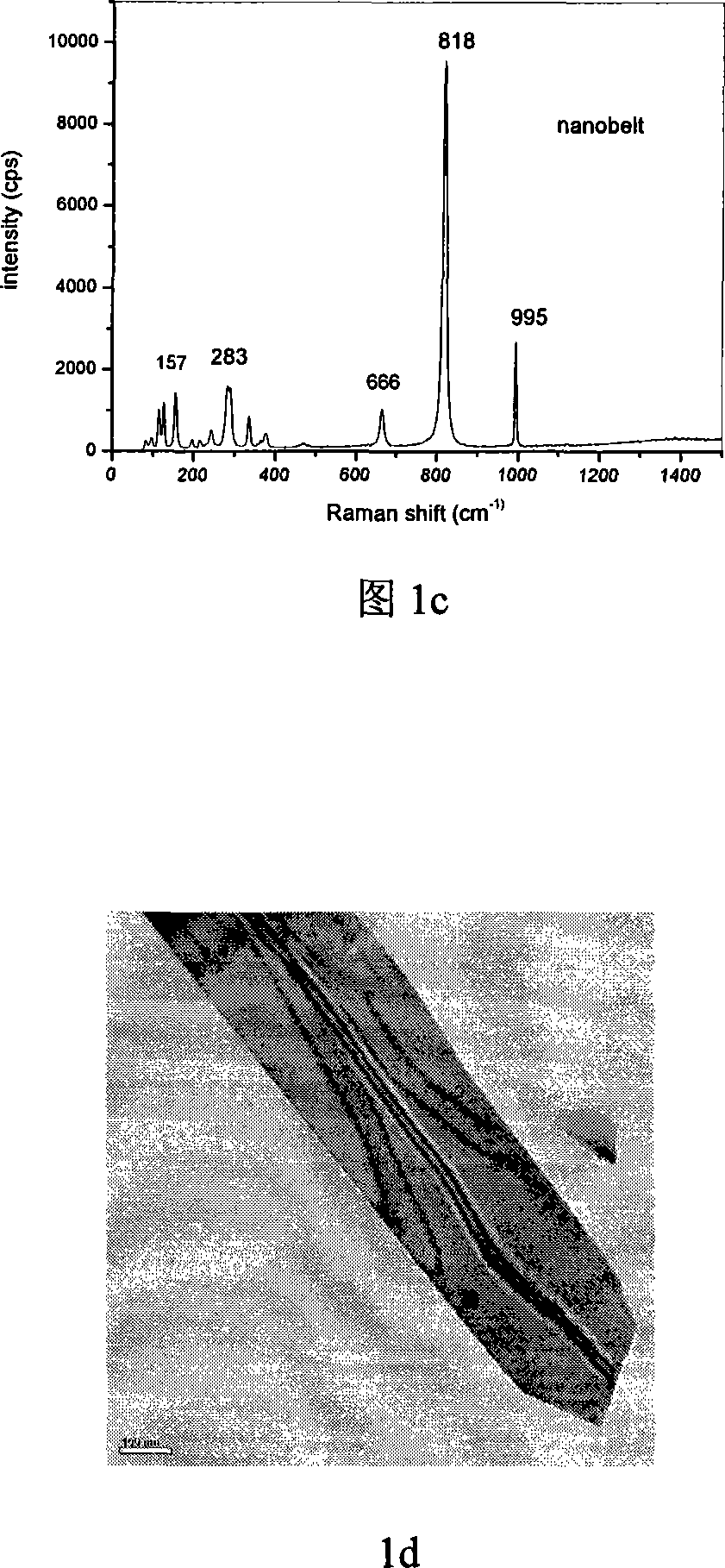

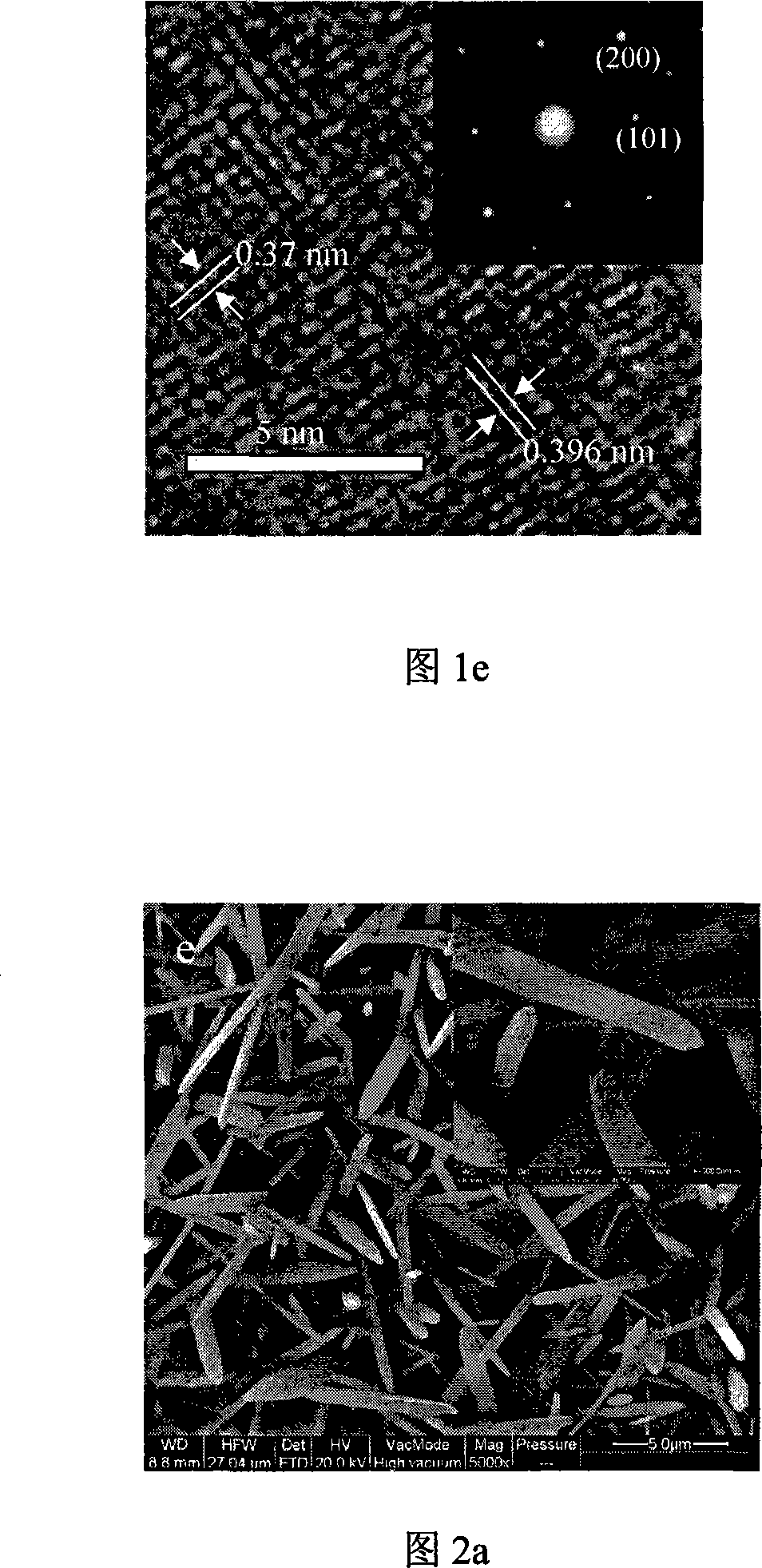

[0055] For the molybdenum trioxide nanostructures and thin films prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com