Composite board of titanium / copper, and production method

A composite plate and copper plate technology, applied in the field of electrolysis, can solve the problems of high resistance of lead alloy, increase of cell voltage, heat generation, high cost, etc., achieve uniform current distribution, prolong service life, and reduce heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

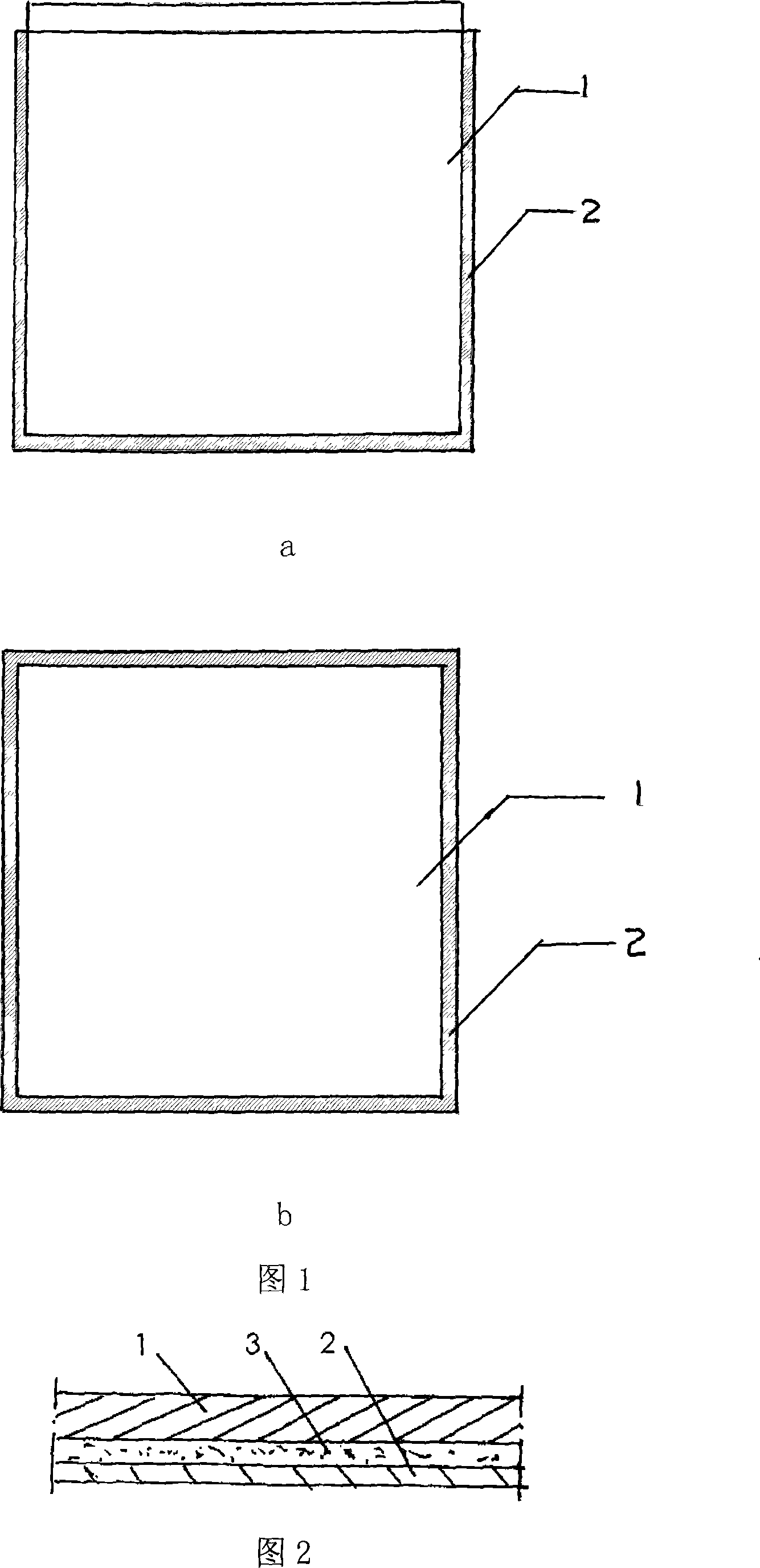

[0020] The surface of the 100×100×10mm copper plate is degreased, cleaned, and sandblasted, and the copper plate is wrapped with a 2mm thick titanium plate, and the titanium plate is welded by argon arc welding to make a titanium / copper composite plate. Then rolling is carried out as required, and annealing is carried out at 850°C for 30 minutes to make a titanium / copper composite plate.

Embodiment 2

[0022] Electroplate or vapor-deposit a 2um silver layer on the surface of a 300×400×10mm copper plate (as shown in Figure 2), at H 2 Heating at 800-1000° C. under a protective atmosphere makes a layer of silver-copper alloy formed on the surface of the copper plate. Other conditions are the same as in Example 1 to make a titanium / copper composite plate.

Embodiment 3

[0024] The surface of the Φ50×100mm copper plate is degreased, cleaned, sandblasted, etc., and assembled with a titanium sleeve with Φ51×Φ60×105mm, and the other end is vacuum-welded by argon arc welding, and first forged into a 40mm thick The "cake" is rolled at 600-800°C, and then cold-rolled on the surface to produce a titanium / copper composite plate with a thickness of 30mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com