Connecting rod for a combustion engine and method for coating the plain bearing surfaces thereof

A technology for sliding bearings and internal combustion engines, applied in the direction of connecting rod bearings, bearings, bearing components, etc., can solve the problems of irregular layer thickness reduction, inability to ensure accurate bearing clearance adjustment, etc., to achieve improved lubrication characteristics, long service life, improved persistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

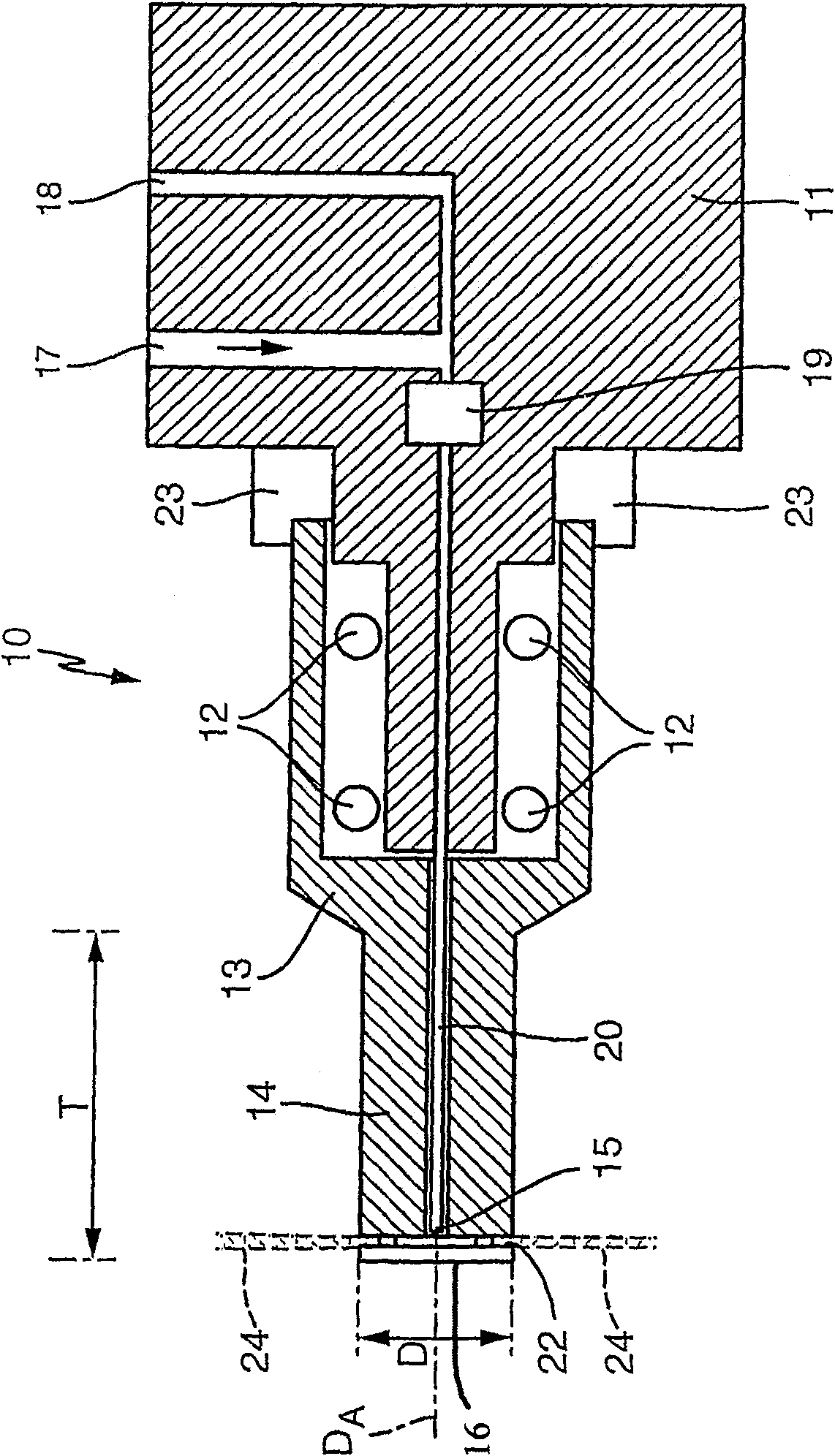

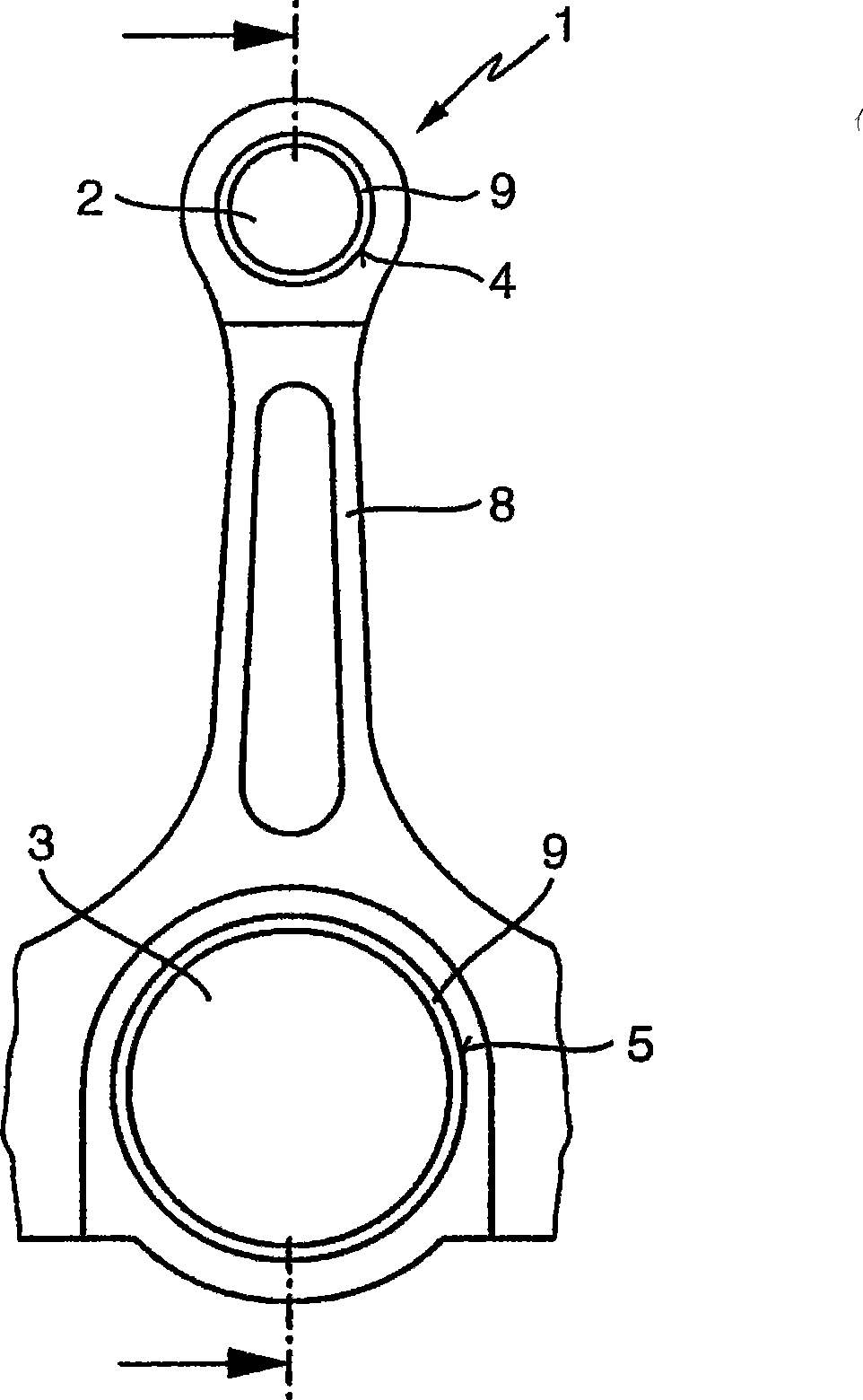

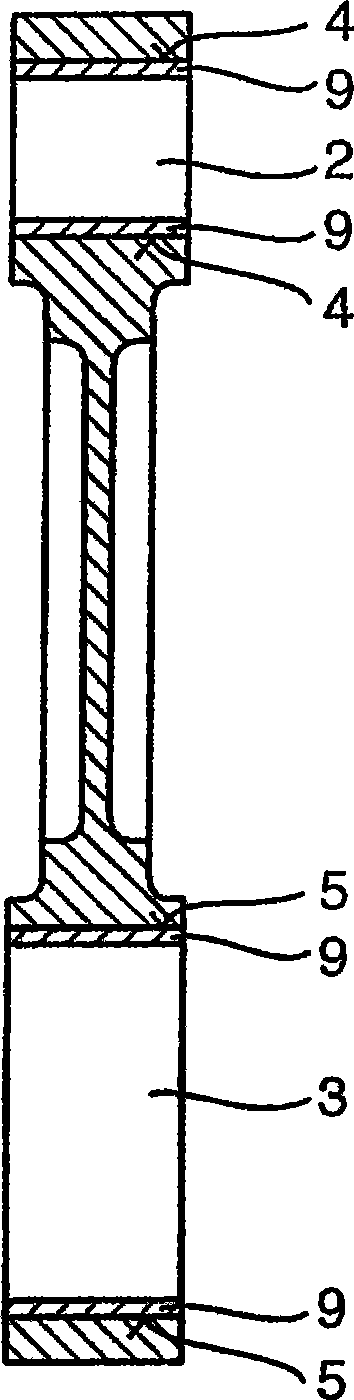

[0026] Coating in the small end hole of the connecting rod:

[0027] The connecting rod 1 is machined in a known manner. The small head hole 2 of the connecting rod is precisely opened with a surface roughness of Rz (average peak-to-valley height)<6.3 μm. At the same time, the diameter of the opening before coating is selected such that the piston pin obtains a diameter gap of 30-40 μm. The small head hole of the connecting rod can obtain a spherical shaped opening. Afterwards, the connecting rod is cleaned so as to completely remove debris, particles, machining oil (motor oil) and the like.

[0028] In preparation for coating, cover plates 21 are installed on both sides of the connecting rod head hole, which cover plates match the outer contour of the connecting rod small head hole. Cover plate 21 can prevent from being painted on the outside of connecting rod.

[0029] The lubricating varnish made of a matrix resin polyamideimide with good high temperature resistance con...

Embodiment 2

[0034] Coating in connecting rod pinholes with grease holes:

[0035] The connecting rod 1 is machined and cleaned substantially according to Example 1. Only the connecting rod head bore diameter was designed to have a radial piston pin clearance of 20-30 μm before coating.

[0036] In preparation for coating, cover plates 21 are installed on both sides of the connecting rod head hole, which cover plates match the outer contour of the connecting rod small head hole. The cover plate 21 prevents the outside of the connecting rod from being painted.

[0037]The lubricating varnish made of a base resin polyamideimide with good high temperature resistance contains graphite as solid lubricant material, the graphite having a particle size of 1-3 μm. The viscosity of the lubricating varnish is adjusted in such a way that drops do not form, but sufficient spreadability is possible.

[0038] Lubricating paint cannot be added in the lubricating oil hole 7 that is centrally arranged in...

Embodiment 3

[0043] Coating in the pinholes of phosphated connecting rods:

[0044] The connecting rod 1 is machined and cleaned substantially according to Example 1. The diameter of the connecting rod bore is selected before coating in such a way that the piston pin obtains a radial play of 30-40 μm.

[0045] Afterwards, the upper half of the connecting rod 1 is phosphating. A commercial phosphating solution, that is, Gardobond G 4098 from Fa. Chemetall in Frankfurt, can be used as the phosphating treatment solution. The phosphating process produces an approximately 5 μm thick layer consisting of iron-manganese-phosphate. On the one hand, this layer serves as an adhesion basis for the paintwork, and on the other hand, it has very good lubricating and separating properties and, in conjunction with the lubricating varnish coating, together prevents the piston pin from jamming in the small end hole of the connecting rod .

[0046] For phosphating the upper half of the connecting rod, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com