Novel process for producing microcolor filter array

A filter array, filter technology, applied in the direction of filter, photolithography process of pattern surface, metal material coating process, etc., can solve incompatibility, limit the further improvement of integration, micro-filtering The edge of the film is uneven and other problems, so as to achieve the effect of improving the accuracy and the edge effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

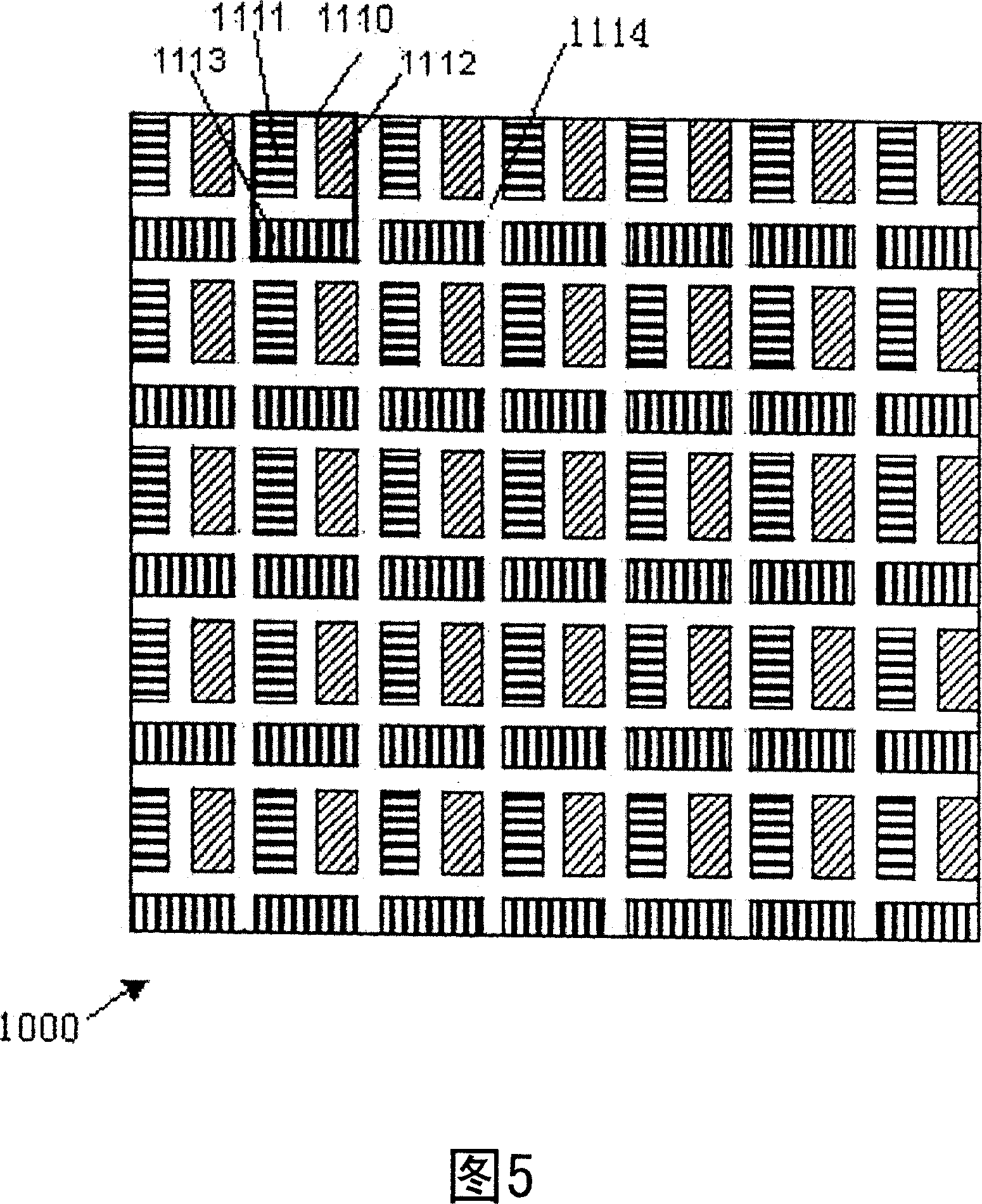

[0013] Figure 5 illustrates an example of a microfilter array that can be used for color LCoS. The micro filter array 1000 is composed of many basic units 1100 evenly arranged, and each basic unit 1100 is composed of three different optical filters, namely blue filter 1111, green filter 1112 and red filter. sheet 1113, and a certain gap 1114 is left between each filter. The processes of the following embodiments will be illustrated by making the example shown in FIG. 5 . Of course, these processes can also be used to fabricate other types of microfilter arrays.

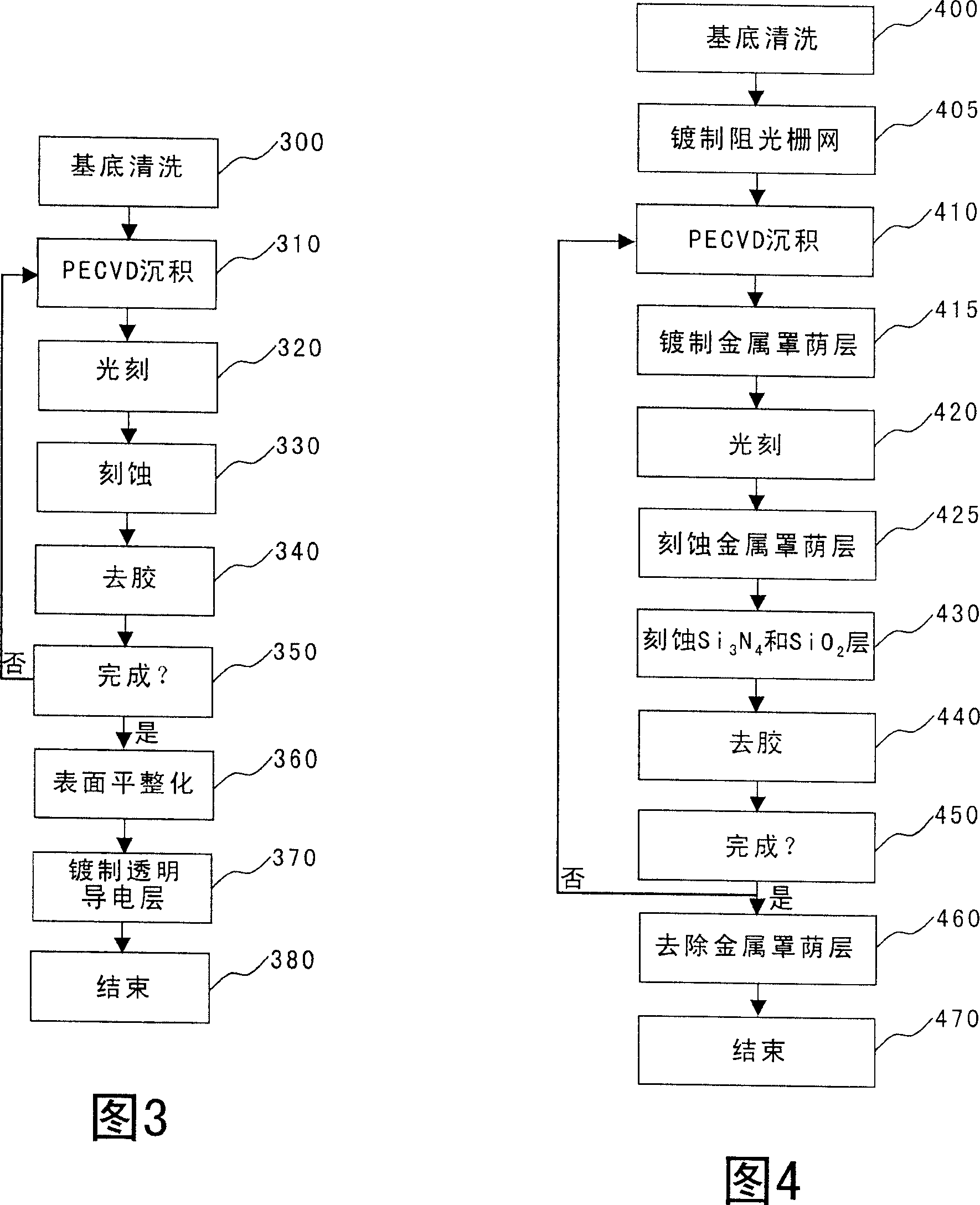

[0014] Figure 2 illustrates a novel process for fabricating a microfilter array according to the present invention. As shown in FIG. 2 , in step 200 , substrate cleaning is performed, and the substrate cleaning in step 200 is basically the same as that in step 100 . In one embodiment, the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com