Method of manufacturing fulvestrant sustained-release microspheres

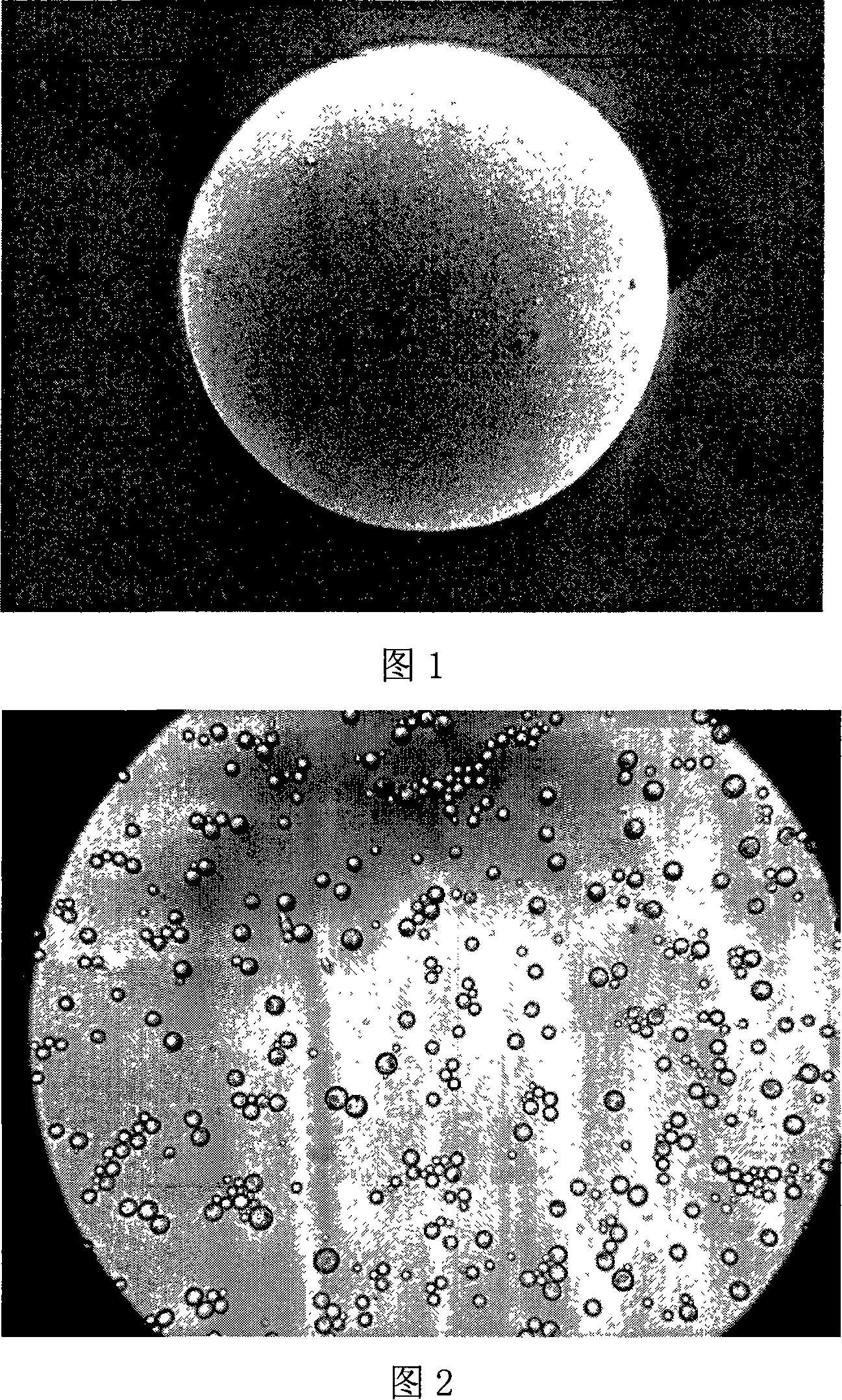

A technology of fulvestrant and sustained-release microspheres, which is applied in the field of preparation of fulvestrant sustained-release microspheres, can solve the problems of short biological half-life, poor stability, hindered application, etc., and achieves round shape and particle size distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Accurately weigh PLA 750mg and medicine fulvestrant 75mg and dissolve in the mixed solution of 15ml dichloromethane and ethyl acetate (the volume percentage of dichloromethane and ethyl acetate is 4: 1) to make oil phase, the relative molecular mass of PLA is in 1.0×10 4 ~1.5×10 5 Between; inject the oil phase into 400ml containing 1% (g / ml) PVA and 0.1% (g / ml) Tween80 aqueous solution (water phase) and stir 1h under 800rpm, form O / W type emulsion, again under 400rpm Stir for 4 hours until the organic solvent is completely evaporated, centrifuge at 6000 rpm for 10 minutes, wash with distilled water 4 times, collect the microspheres, and vacuum dry at room temperature for 24 hours to obtain the fulvestrant sustained-release microspheres. The average particle size of the microspheres is 23.7 μm, the drug loading capacity is 7.29%, and the encapsulation efficiency is 80.2%.

Embodiment 2

[0027] Accurately weigh 350mg of PLGA and 50mg of drug fulvestrant and dissolve in 5ml of dichloromethane to make an oil phase. The relative molecular mass of PLGA is 1.0×10 4 ~1.5×10 5 Between; The oil phase is injected into 400ml and contains 2% (g / ml) PVA, 0.1% (g / ml) Tween80 and 1% (g / ml) NaCl aqueous solution (water phase) and stir 2h under 1100rpm, form O / W type emulsion, then stirred at 400rpm for 12h until the organic solvent evaporated completely, centrifuged at 3500rpm for 15min, washed 4 times with distilled water, collected microspheres, -40°C, 4h; -30°C, 10h; -10°C, 20h freeze-dried The fulvestrant sustained-release microspheres were obtained. The average particle size of the microspheres is 85.4 μm, the drug loading capacity is 11.6%, and the encapsulation efficiency is 92.8%.

Embodiment 3

[0029] Accurately weigh PLGA 600mg and drug fulvestrant 100mg to be dissolved in the mixed solution of 2ml methylene chloride and ethyl acetate (the volume percentage of methylene chloride and ethyl acetate is 4: 1) to make oil phase, the relative molecular mass of PLGA is in 1.0×10 4 ~1.5×10 5 Between; inject the oil phase into 400ml containing 1% (g / ml) PVA, 0.1% (g / ml) Tween80 emulsification 30s at a high speed under 10000rpm, form O / W type emulsion, then stir 1h at 400rpm to organic The solvent was completely evaporated, centrifuged at 3500 rpm for 15 minutes, washed with distilled water 4 times, collected the microspheres, and dried in vacuum at room temperature for 48 hours to obtain fulvestrant sustained-release microspheres. The average particle size of the microspheres is 32.3 μm, the drug loading capacity is 13.0%, and the encapsulation efficiency is 91.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com