Fast heating intelligent leadless welding table controller and control method thereof

A lead-free soldering station and controller technology, applied in the field of soldering electric irons, can solve the problems of shortened service life, return temperature difference, small heat capacity, etc., and achieve the effects of prolonging service life, high constant temperature accuracy and preventing empty burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

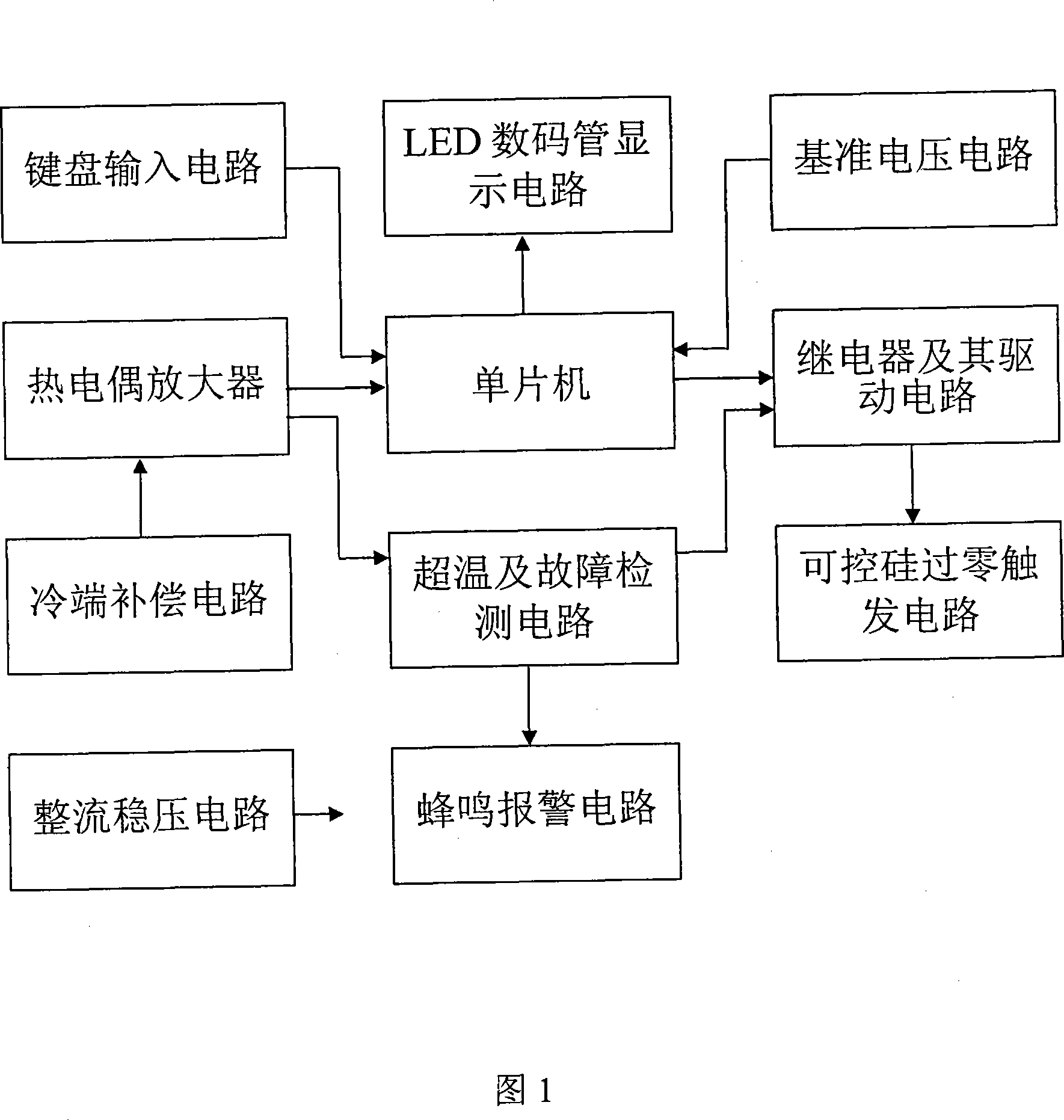

[0016] Referring to attached drawings 1 to 3, the rapid heating intelligent lead-free soldering station controller includes a thermocouple amplifier circuit, a cold junction compensation circuit, a single chip microcomputer, a reference voltage circuit, an over-temperature and fault detection circuit, a buzzer alarm circuit, a relay and its driving circuit , SCR zero-crossing trigger circuit, LED digital tube display circuit, rectification and voltage stabilization circuit, keyboard input circuit, reference voltage circuit.

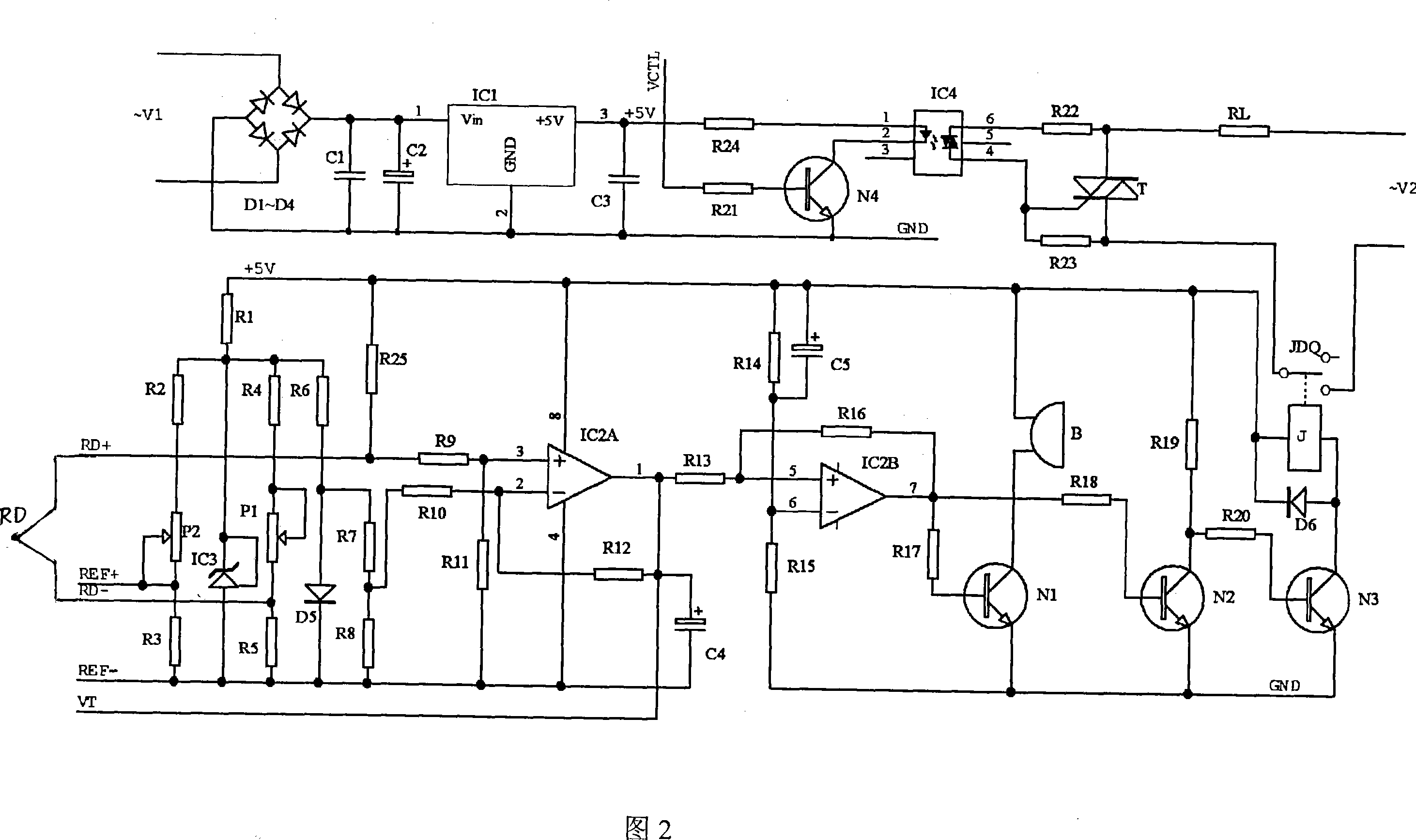

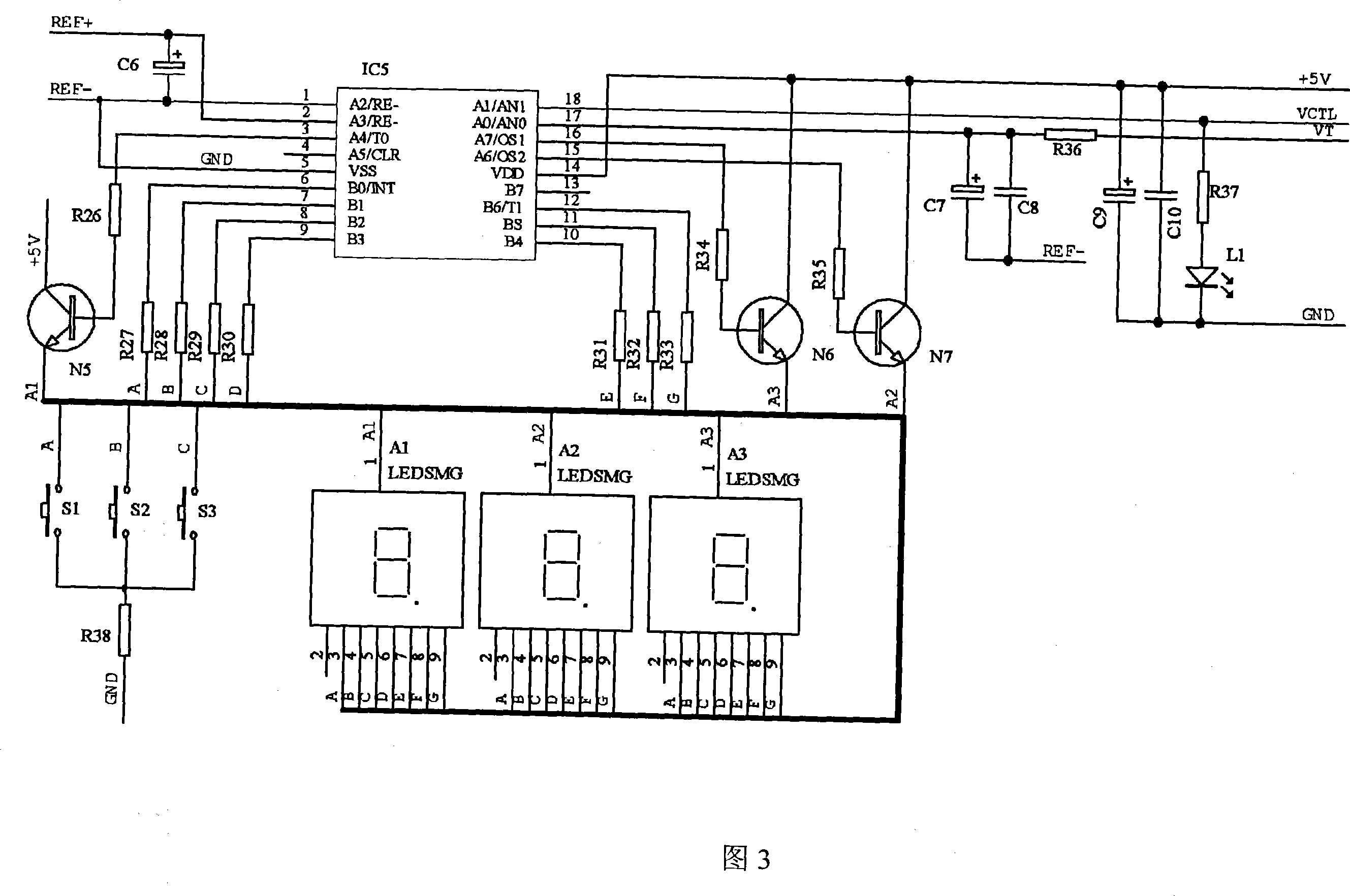

[0017] The thermocouple amplifying circuit is composed of resistors R9-R12, capacitor C4, operational amplifier IC2A, and thermocouple RD. The cold junction compensation circuit is composed of resistors R4-R8, diode D5, and adjustable resistor P1. Single-chip microcomputer IC5 adopts PIC16F819 single-chip microcomputer. The reference voltage circuit is composed of resistors R1 ~ R3, voltage reference IC3, adjustable resistor P2, and capacitor C6. The ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com