Preparation method of mizue brocade straw activated charcoal

A technology of straw activated carbon and water branch brocade, which is applied in the field of preparation of activated carbon, can solve the problems of unsatisfactory adsorption effect of activated carbon, difficulty in centralized collection of fruit shells, and limitation of activated carbon raw materials, and achieve the effect of low price, easy production and large pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

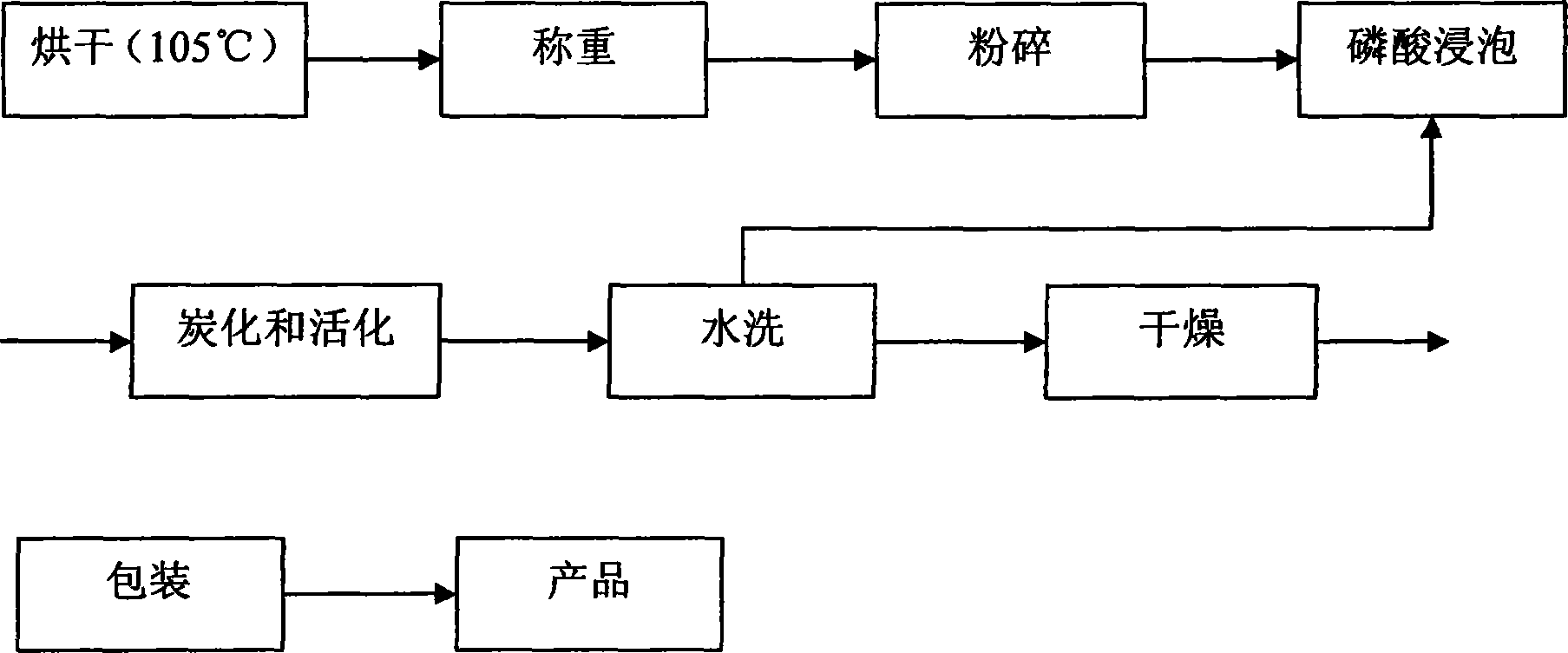

[0011] Shown in the process flow diagram of the present invention that provides as accompanying drawing. Dry the Shuizhijin straw naturally or at 105°C±5°C, and use a pulverizer for coarse and medium crushing until it can pass through a 70-100 mesh sieve; then put the raw materials into the tank in batches, and use Phosphoric acid with a concentration of 50%-70% is soaked at an impregnation ratio of 2.5:1 by mass, and the soaking time is 3-4 hours; then put into an activation furnace for carbonization and activation, the activation temperature is 450°C-500°C, and the activation time 1.5-2.5 hours, or carbonize and activate in a microwave oven with nitrogen as a protective gas, the microwave power should be 1000W, and the microwave irradiation time should be 7-8min; then wash with water, concentrate the first washing liquid, and recover phosphoric acid , for reuse; use multi-stage countercurrent washing for at least three times, and wash with water for the last time until the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com