Fish soluble slurry protein powder and preparation method thereof

A technology for fish-soluble protein powder and fish-soluble pulp is applied in the directions of animal feed, animal feed molding or processing, animal feed, etc., and can solve the problems of unsuccessful, inconvenient use, and increased moisture absorption of fish meal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

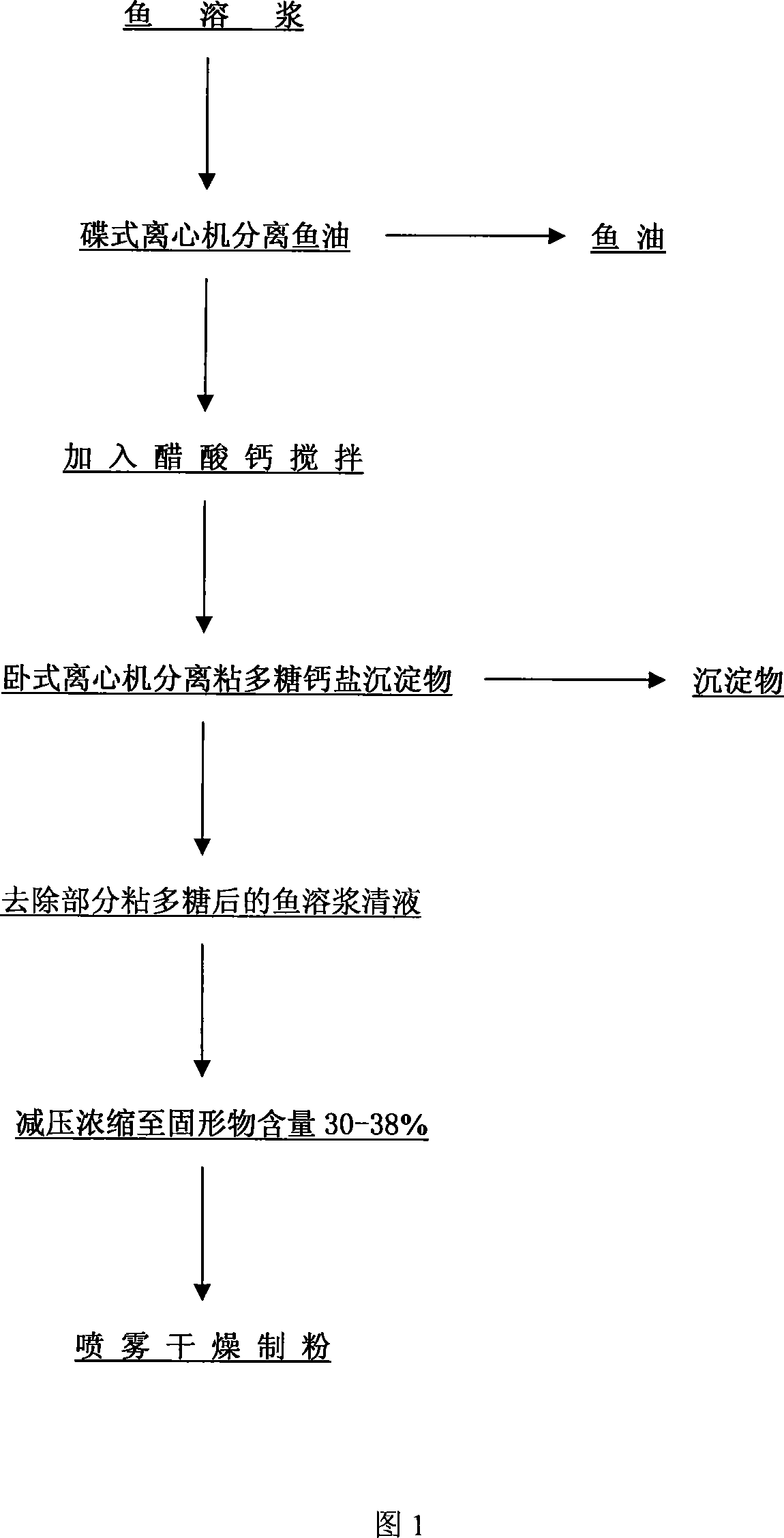

[0032] The specific operation steps of the preparation method of fish soluble protein powder of the present invention are as follows:

[0033] (1) Send the fish soluble slurry flowing out of the fishmeal production line into a disc centrifuge at a speed of about 6000 rpm, the light phase is fish oil, and put it into a special fish oil storage tank. The heavy phase is deoiled fish slurry, which is sent to the mixing tank.

[0034] (2) Control the temperature of the mixing tank to be 60° C., add 1% calcium acetate under stirring, stir for 10 minutes, and then send it into a horizontal centrifuge.

[0035] (3) Adjust the rotating speed of the horizontal centrifuge to 4000 rpm, the mucopolysaccharide calcium salt precipitate is removed from the slag discharge port, and the fish-dissolved pulp clear liquid flows out from the clear liquid port, and then is sent into the decompression concentrator.

[0036] (4) At 0.02Kg / cm 2 Concentrate the fish soluble slurry under pressure to a ...

Embodiment 2

[0042] The concrete operating steps of the method of the present invention are as follows:

[0043] (1) Send the fish soluble slurry flowing out of the fishmeal production line into a disc centrifuge at a speed of about 7000 rpm, the light phase is fish oil, and put it into a special fish oil storage tank. The heavy phase is deoiled fish slurry, which is sent to the mixing tank.

[0044] (2) Control the temperature of the mixing tank to be 30° C., add 2% calcium acetate under stirring, stir for 30 minutes, and then send it into a horizontal centrifuge.

[0045] (3) Adjust the rotational speed of the horizontal centrifuge to 5000 rpm, the mucopolysaccharide calcium salt precipitate is removed from the slag discharge port, and the fish-dissolved pulp clear liquid flows out from the clear liquid port, and then is sent into the decompression concentrator.

[0046] (4) At 0.02Kg / cm 2 Concentrate the fish soluble slurry under pressure to a solid content of about 30%.

[0047] (5)...

Embodiment 3

[0050] The concrete operating steps of the method of the present invention are as follows:

[0051] (1) Send the fish soluble slurry flowing out of the fishmeal production line into a disc centrifuge at a speed of about 9000 rpm, the light phase is fish oil, and put it into a special fish oil storage tank. The heavy phase is deoiled fish slurry, which is sent to the mixing tank.

[0052] (2) Control the temperature of the mixing tank to be 30° C., add 4% calcium acetate under stirring, stir for 30 minutes, and then send it into a horizontal centrifuge.

[0053](3) Adjust the rotational speed of the horizontal centrifuge to 5000 rpm, the mucopolysaccharide calcium salt precipitate is removed from the slag discharge port, and the fish-dissolved pulp clear liquid flows out from the clear liquid port, and then is sent into the decompression concentrator.

[0054] (4) At 0.02Kg / cm 2 Concentrate the fish soluble slurry under pressure to a solid content of about 50%.

[0055] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com