Irreversible hydrogen-absorbing material, product and preparation method

A technology for hydrogen-absorbing materials and products, applied in chemical instruments and methods, and other chemical processes, can solve problems such as high melting point, poor safety, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

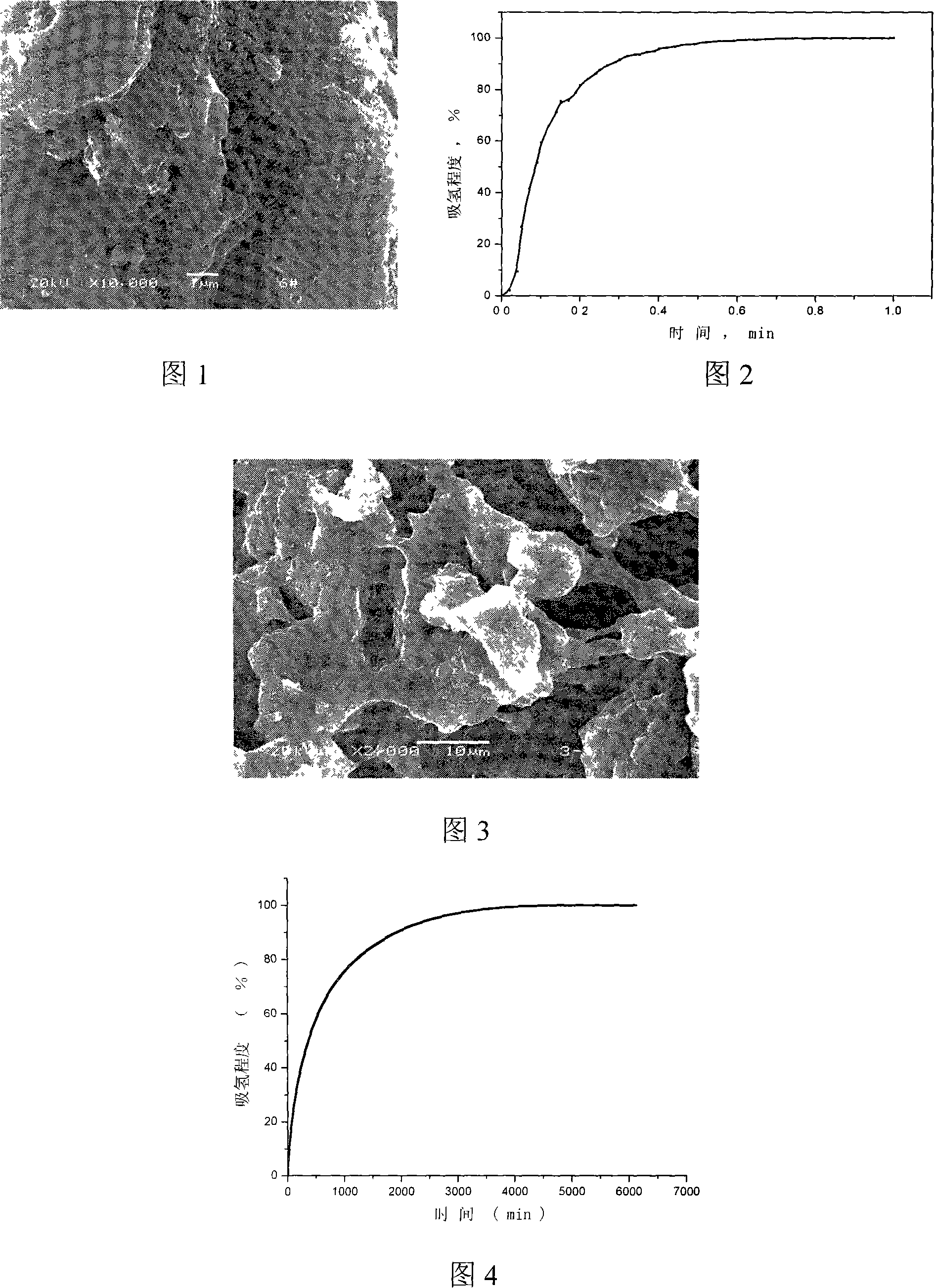

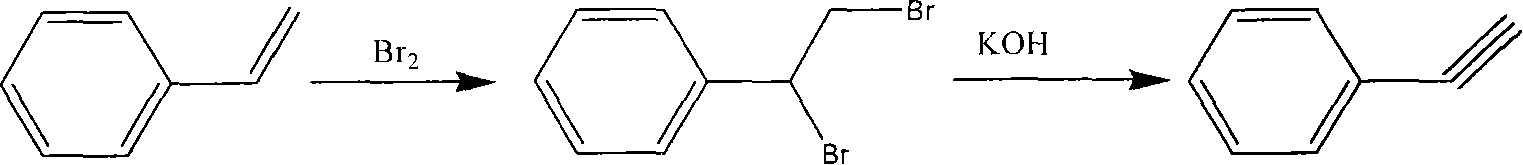

[0054] Example 1 Preparation of DEB-Pd / C irreversible hydrogen absorber composite powder material

[0055] Add 75g of organic alkyne compound DEB into 250ml of chloroform, stir at 75°C for 1h to form a homogeneous system, and obtain a uniformly dispersed DEB solution. In this solution, add 25g of Pd / C catalyst (Pd content 10%wt, the specific surface area of gac support greater than 800m 2 g -1 , particle size 80 ~ 40 mesh), continue to stir at 70 ° C for 2 hours to obtain a uniformly dispersed mixed solution. Put this mixture into an ultrasonic generator with a frequency of 28kHz and a power of 100W for ultrasonic treatment for 15min. The mixture after ultrasonic treatment was stirred in an open environment at 85° C. for 5 h to evaporate the solvent to obtain a primary complex. This primary complex at 100°C, 10 -2 After vacuum drying for 24h under pa condition, DEB-Pd / C irreversible hydrogen absorber composite powder material was obtained. After testing, the microscopic...

Embodiment 2

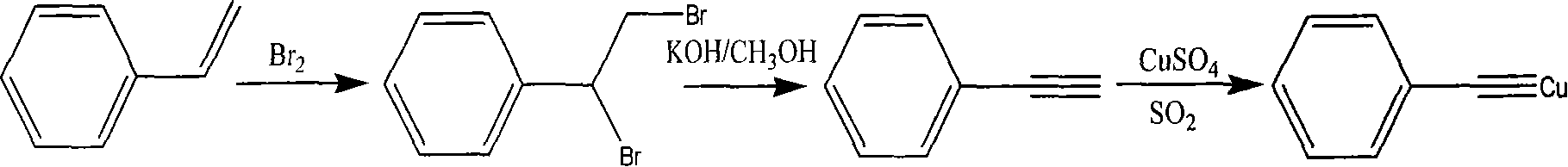

[0056] Embodiment 2DPBD-Pt / BaSO 4 Preparation of Irreversible Hydrogen Absorber Composite Powder Material

[0057] Add 20 g of organic alkyne compound DPBD into 350 ml of n-hexane / tetrahydrofuran mixed solution with a volume ratio of 1:1, and stir at 75° C. for 1.5 h to form a uniformly dispersed homogeneous solution system. Add 80 g of Pt / BaSO4 activated with flowing hydrogen at 100°C to the solution 4 Catalyst (Pt content 3%wt, BaSO 4 The specific surface area is greater than 5m 2 g -1, the particle size is 80-100 mesh), and the stirring is continued at 65° C. for 3 h to obtain a uniformly dispersed mixed solution. Put this mixture into an ultrasonic generator with a frequency of 45kHz and a power of 80W for 30min. After the ultrasonically treated mixture was stirred in an open environment at 65°C to evaporate the solvent, the primary complex was obtained. This primary complex at 85°C and 10 -2 Vacuum drying treatment under pa conditions, to obtain DPBD-Pt / BaSO 4 Irr...

Embodiment 3

[0058] Example 3 Packed TEB-Pd-Ru / γ-Al 2 o 3 Preparation of Irreversible Hydrogen Absorber Composite Powder Material Products

[0059] Add 30 g of organic alkyne compound TEB into 400 ml of tetrahydrofuran, and stir for 1 h at 80° C. to form a uniformly dispersed homogeneous system solution. Add 70g of Pd-Ru / γ-Al activated by flowing hydrogen at 250°C to the solution 2 o 3 Catalyst (Pd and Ru mass percentages are respectively 4% and 1%, γ-Al 2 o 3 The specific surface area is greater than 250m 2 g -1 , with a particle size of 100-80 mesh), and continued stirring at 90°C for 0.5h to obtain a uniformly dispersed mixed solution. Put this mixture into an ultrasonic generator with a frequency of 100 kHz and a power of 100 W for ultrasonic treatment for 20 min. The mixture solution after ultrasonic treatment was stirred in an open environment at 75° C. for 6 h to evaporate the solvent, and the primary complex was obtained. This primary complex at 120°C, 10 -2 After vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com