Making method for multi-crystal TFT array of active driven organic EL display screen

A production method and luminescent technology, which are applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as difficulty, high cost, and complex process of polysilicon thin-film transistor arrays, and achieve the effect of simple process and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

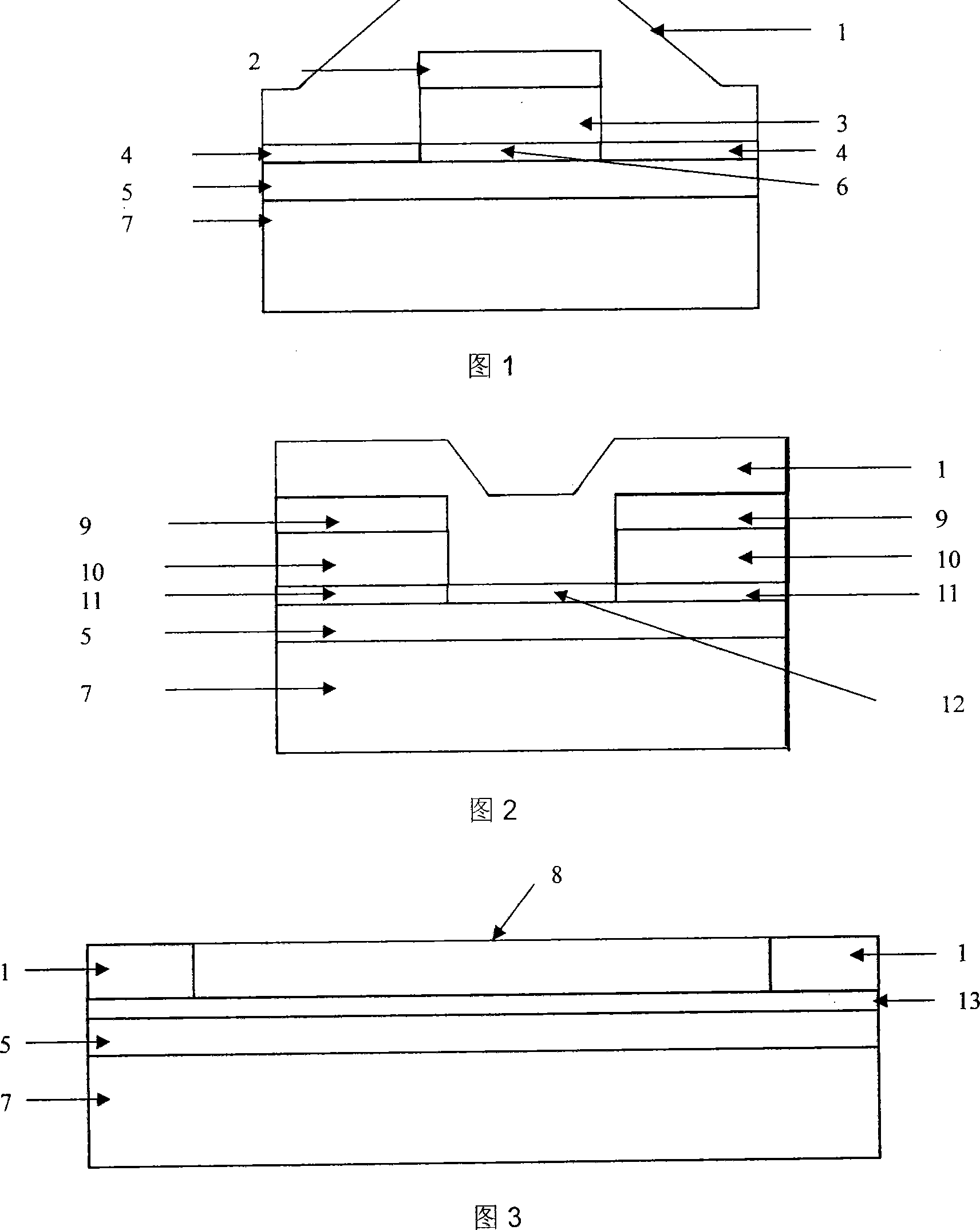

[0071] (1) On the annealed 100mm Corning 1737 glass substrate 7, ultrasonic cleaning with organic solvents such as toluene, acetone, ethanol, cleaning, drying with a nitrogen gun, PECVD method (TEOS, Tetra-Ethyl -Ortho-Silicate) decomposition, the substrate temperature is 350°C) deposition of 500nm low temperature silicon oxide (LTO: low temperature oxide) buffer layer 5 to block impurities in the glass;

[0072] (2) PECVD method deposits 60nm intrinsic amorphous silicon (a-Si) layer 14, substrate temperature 200℃, background vacuum 2×10 -4 pa, reaction chamber pressure 80pa, SiH 4 Flow rate 40sccm;

[0073] (3) PECVD method to deposit 60nm SiN x Insulation layer 15, using SiH 4 And NH 3 Mixed gas, substrate temperature 270℃, reaction chamber pressure 30Pa;

[0074] (4) Sputtering 30 induces the metal (Ni) layer 16, the substrate temperature is 130°C, and the background vacuum is 2×10 -4 Pa, the pressure of the reaction chamber during sputtering is 0.1 Pa; then, the a-Si amorphou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com