Low fish powder feed for litopenaeus vannamei

A low-fishmeal, vanabine technology, applied in animal feed, animal feed, climate change adaptation, etc., can solve the problems of increasing costs for feed manufacturers and breeding producers, restricting the development of large-scale shrimp farming, and high ammonia nitrogen ring emissions , to facilitate large-scale promotion, improve feed utilization, and reduce ammonia nitrogen emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

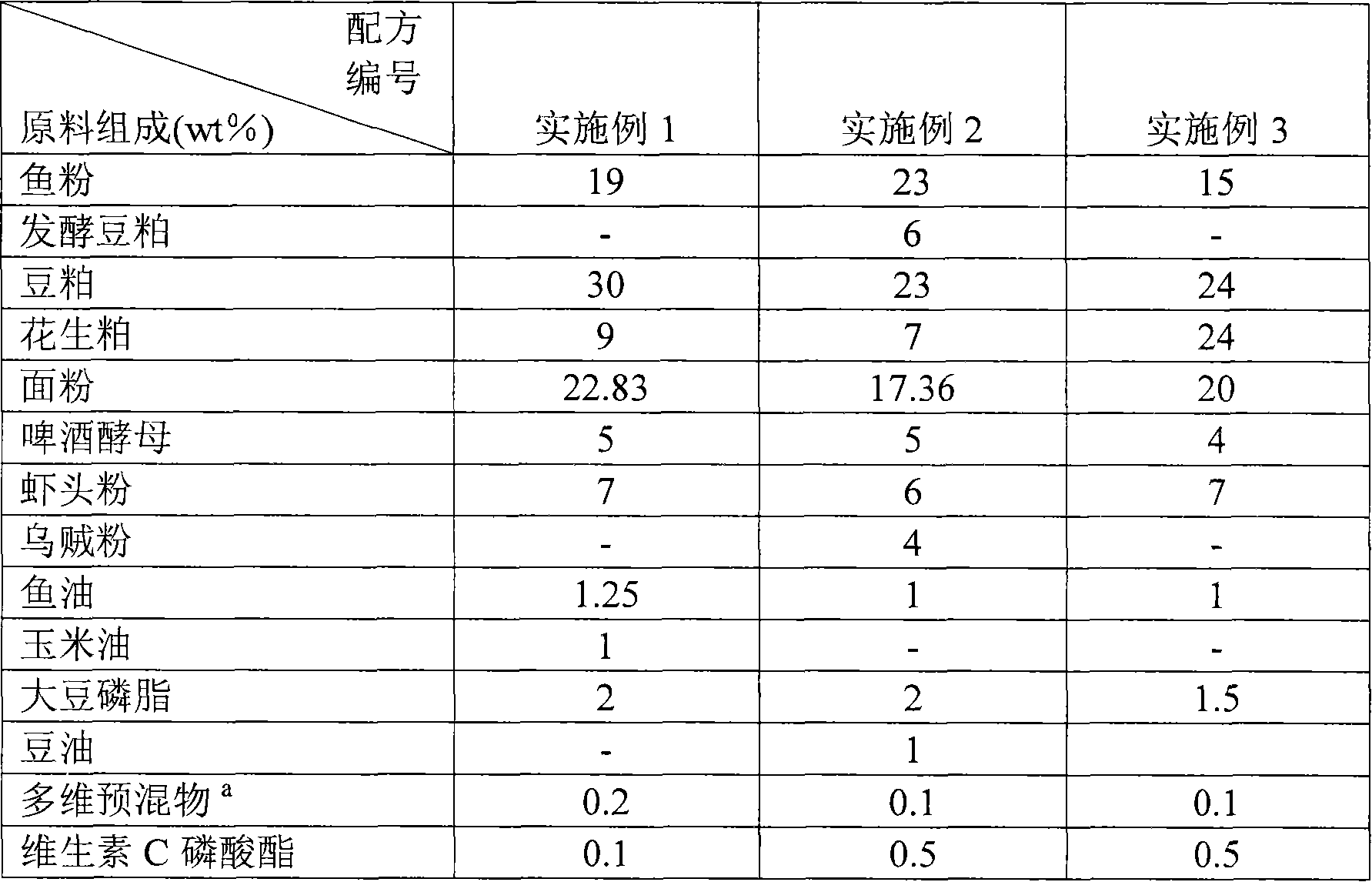

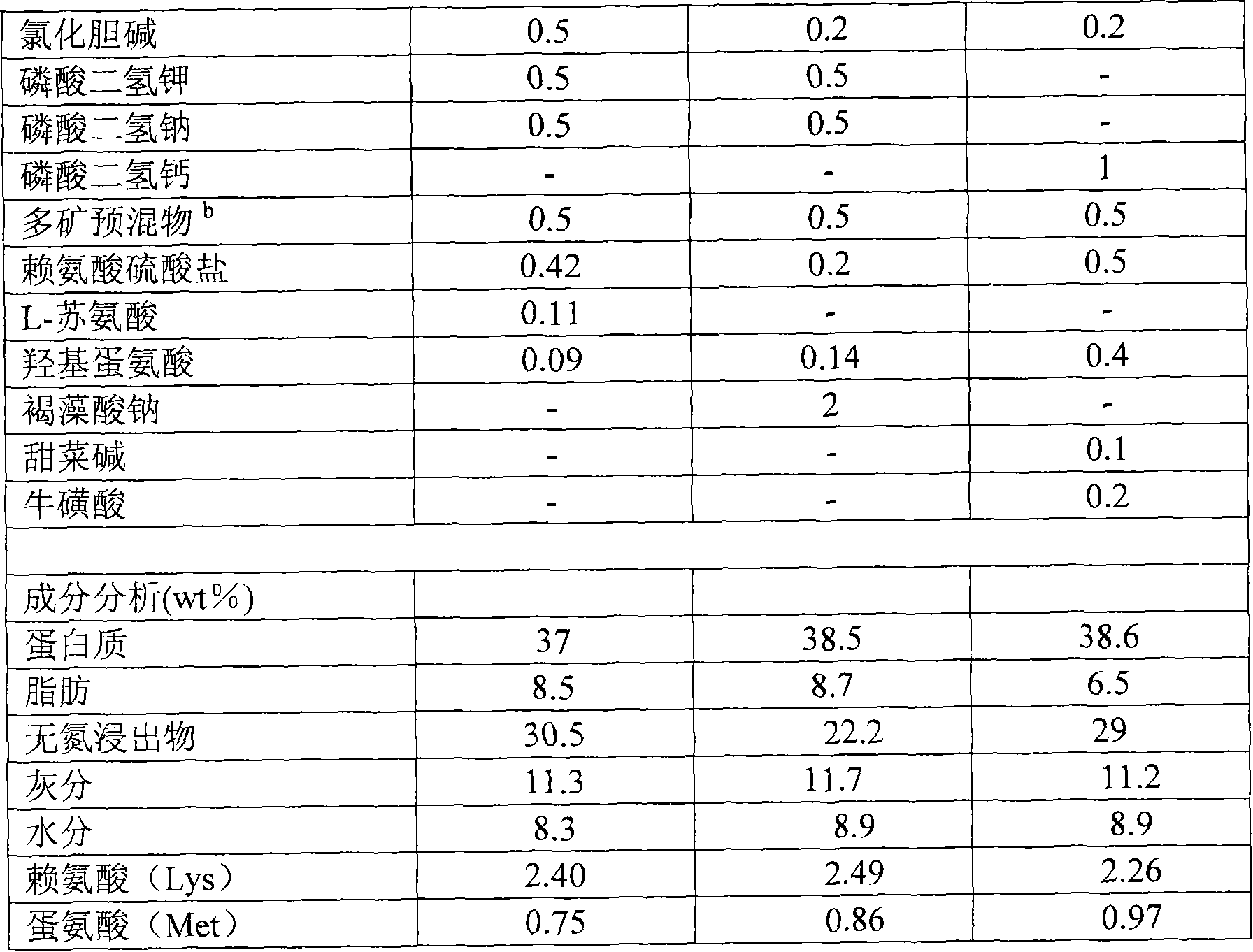

[0020] Prepare feed with Formula 1 shown in Table 1, raise 0.37g Litopenaeus vannamei for 70 days, feed factor 1.05, specific growth rate (SGR, %d -1 ) 3.86, growth rate 1394.4%, survival rate 93.8%, protein efficiency 2.26, protein digestibility 84.9%, each parameter has no significant difference with the control group (22% fish meal, no crystalline amino acid added), feed coefficient even It is slightly lower than the control group (1.09), while the protein efficiency is higher than the control group (2.05).

Embodiment 2

[0022] Prepare the feed with Formula 2 shown in Table 1, raise and raise 0.42g Litopenaeus vannamei in the cement pond for 28 days, the feed coefficient is 1.10, the growth rate is 271.6%, the feed efficiency is 90.8%, the protein efficiency is 2.36, and the survival rate is 98.44%. The parameters were not significantly different from those of the control group (28% fishmeal, no fermented soybean meal, crystalline amino acid), and the survival rate was even slightly higher than that of the control group (98%).

Embodiment 3

[0024] Prepare the feed with Formula 3 shown in Table 1, raise 0.35g Litopenaeus vannamei for 42 days in the cement pond, the growth rate is 573%, and the specific growth rate is 4.5%d -1 , the survival rate is 80%, the feed coefficient is 1.15, and the protein efficiency is 2.25. All parameters are not significantly different from those of the control group (25% fishmeal, without adding crystalline amino acids), and the growth rate is slightly higher than that of the control group (558.9%). The specific growth rate was the same.

[0025] Calculation formula:

[0026] Specific growth rate SGR (%d -1 )=100×(ln final average weight-ln initial average weight) / experimental days

[0027] Weight gain rate WG(%)=(final average weight-initial average weight)×100 / initial average weight

[0028] Survival rate SR (%) = number of remaining shrimp tails at the end of the experiment × 100 / number of shrimp tails at the beginning of the experiment

[0029] Feed coefficient (FCR) = feed am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com