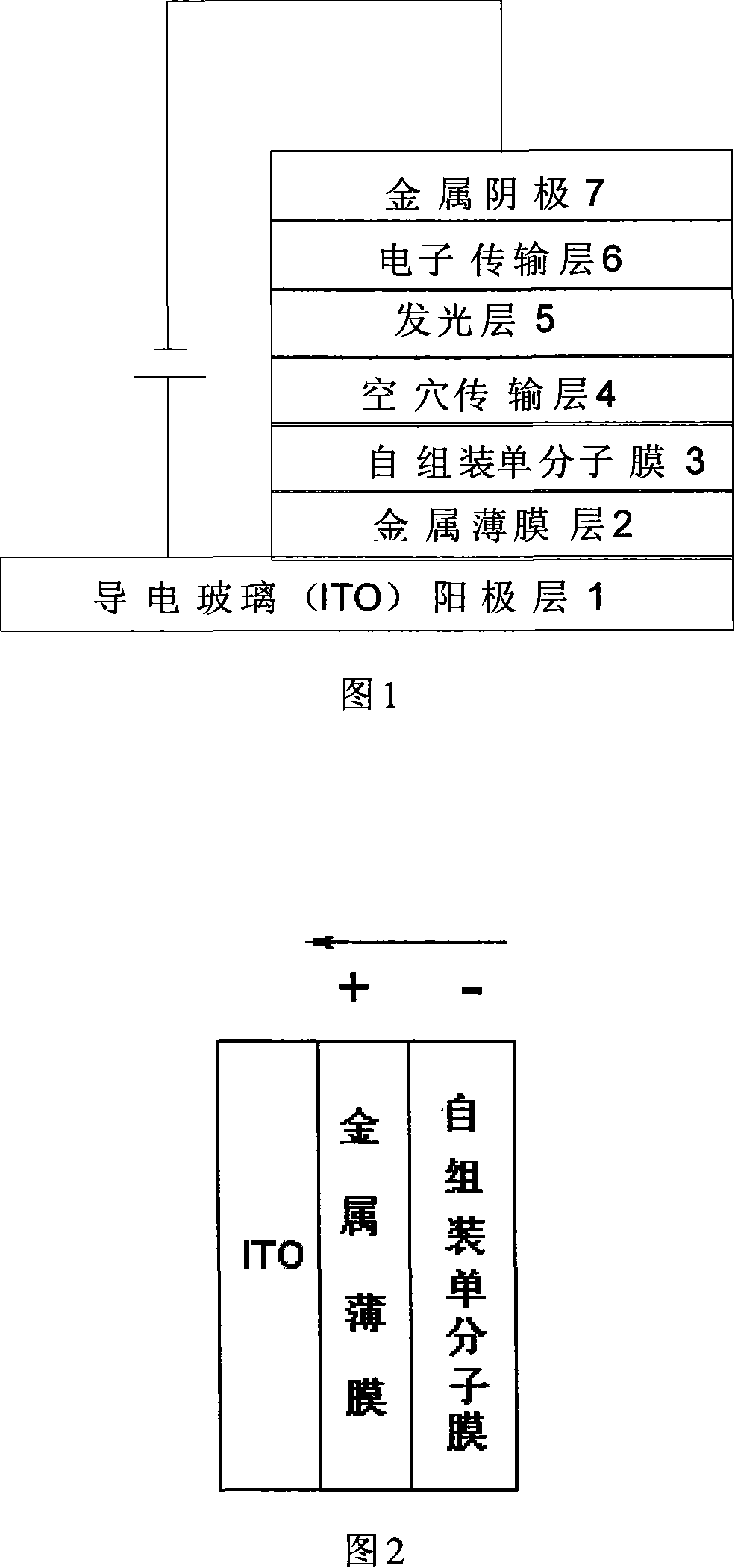

Organic electroluminescent device with novel structure and method for fabricating the same

An electroluminescence and device technology, applied in the field of organic electroluminescence devices, can solve problems such as low device efficiency, and achieve the effects of increasing proportion, improving work function and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) After repeatedly cleaning the 3mm×3mm ITO glass in detergent, soak it in isopropanol, acetone and chloroform solution respectively and ultrasonically clean it, and finally dry it in an infrared oven for use;

[0032] (2) A 12 nm-thick Ag film was evaporated on the surface of the above-mentioned cleaned ITO glass by a vacuum evaporation method.

[0033] (3) Put the above-mentioned ITO glass coated with a 12nm thick Ag film into a concentration of 1×10 -3 mol / L of 3-trifluoromethylbenzyl mercaptan in absolute ethanol solution for 0.5h, take it out, and wash it with absolute ethanol for 3 times. Blow dry with nitrogen stream.

[0034] (4) PVK and TPD were mixed at a mass ratio of 1:1 to 1::2, and dissolved in chloroform to prepare a solution with a concentration of 2 mg / ml. Films were formed on ITO glass by spin coating. Film-forming conditions: low speed 1000-1500rpm, film-forming time about 20s; high-speed 3000-4000rpm, film-forming time about 30s, after completio...

Embodiment 2

[0040] A 12nm thick Ag film was evaporated on the cleaned ITO glass surface by vacuum evaporation method. Put the above-mentioned ITO glass coated with Ag film into the concentration of 1×10 -3 mol / L 4-fluorobenzenethiol in absolute ethanol solution for 0.5h and then taken out. Wash 3 times with absolute ethanol and blow dry with nitrogen flow. 15nm m-MTDATA, 15nm NPB, and 60nm Alq were sequentially deposited by vacuum evaporation method 3 , 1nm LiF and 100nm Al, stable electroluminescence can be obtained between 3.5 and 13.5V. The highest brightness is 13560cd / m at 13.5V 2 ; The maximum luminous efficiency at 13V is 4.3cd / A. The contrast device has a maximum brightness of 10000cd / m at 13.5V 2 , and the corresponding luminous efficiency is 2.4cd / A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com