Low-plastisity metallic hollow profile continuous casing and forming device

A technology of forming equipment and hollow profiles, applied in the field of metallurgical casting, to achieve the effect of uniform composition and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

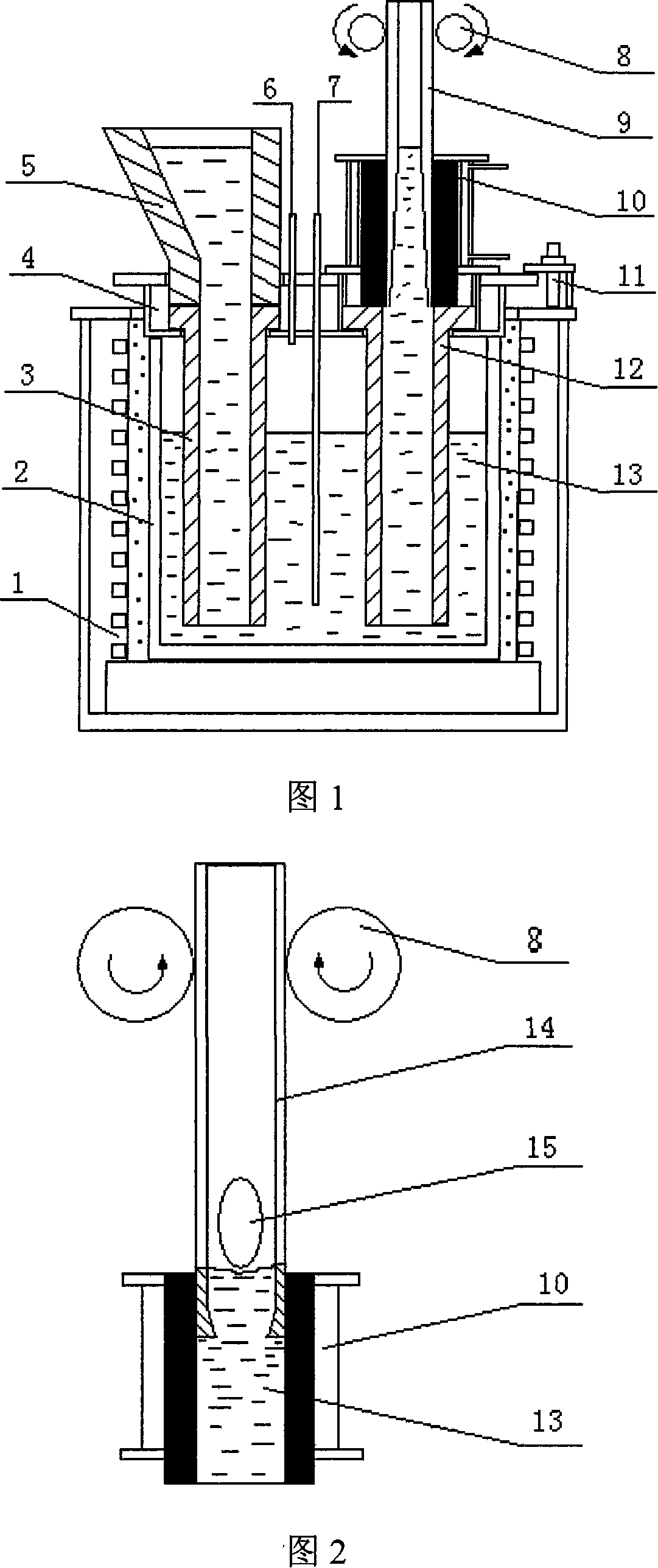

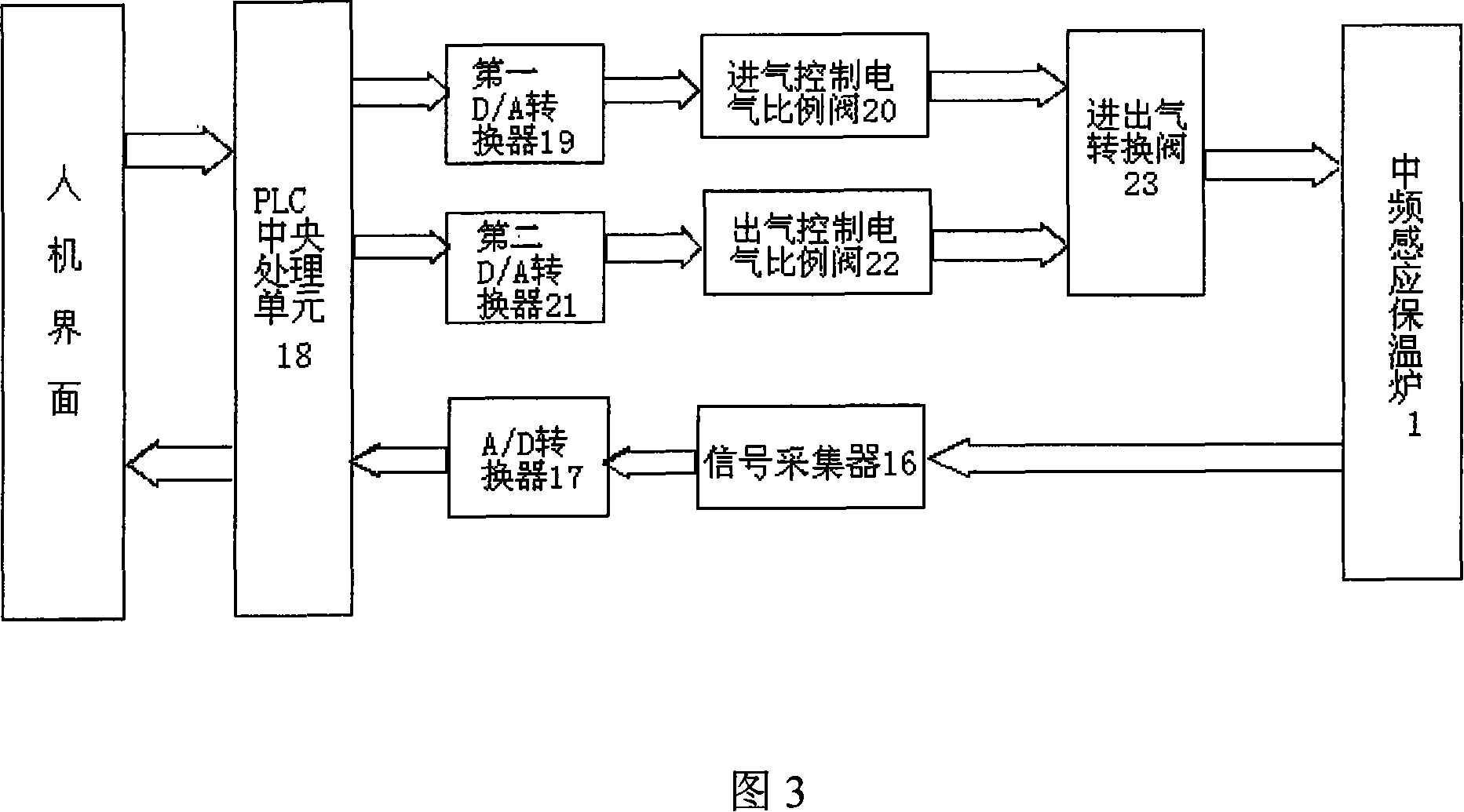

[0020] 1. As shown in Figure 1, the present invention has designed a kind of equipment of vertical upward leading continuous casting hollow profile, mainly is made up of intermediate frequency induction holding furnace 1, multifunctional furnace cover 4, mechanical traction mechanism and air pressure control system. The crucible 2 is placed in the medium frequency induction holding furnace 1, and four holes are opened on the furnace cover 4, two thick and two thin, and the inlet / exhaust pipe 6 and the thermocouple tube 7 are inserted into the thin holes, and the insertion is sealed at high temperature; the two thick holes have steps , the riser pipe 12 made of metallurgical industry nozzle material and the pouring pipe 3 are inserted vertically and parallelly, the flange seat at the top is on the step of the coarse hole, and is sealed with hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com