Equipment system for comprehensive treatment of refinery acid alkali containing waste liquid

A comprehensive treatment and refinery technology, applied in the direction of liquid separation, biological water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems of high infrastructure costs and operating costs, and can not be recovered from them, achieving remarkable governance effects, The effect of small separation equipment and less power equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

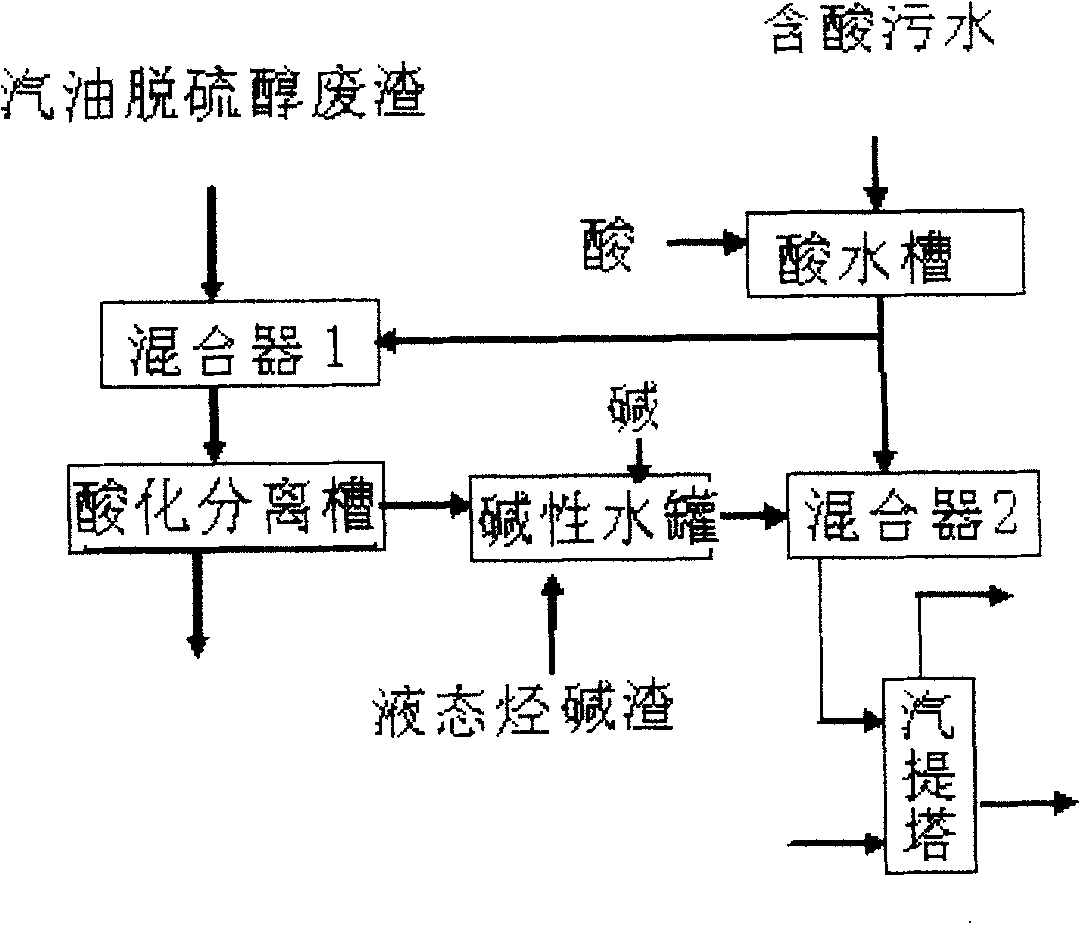

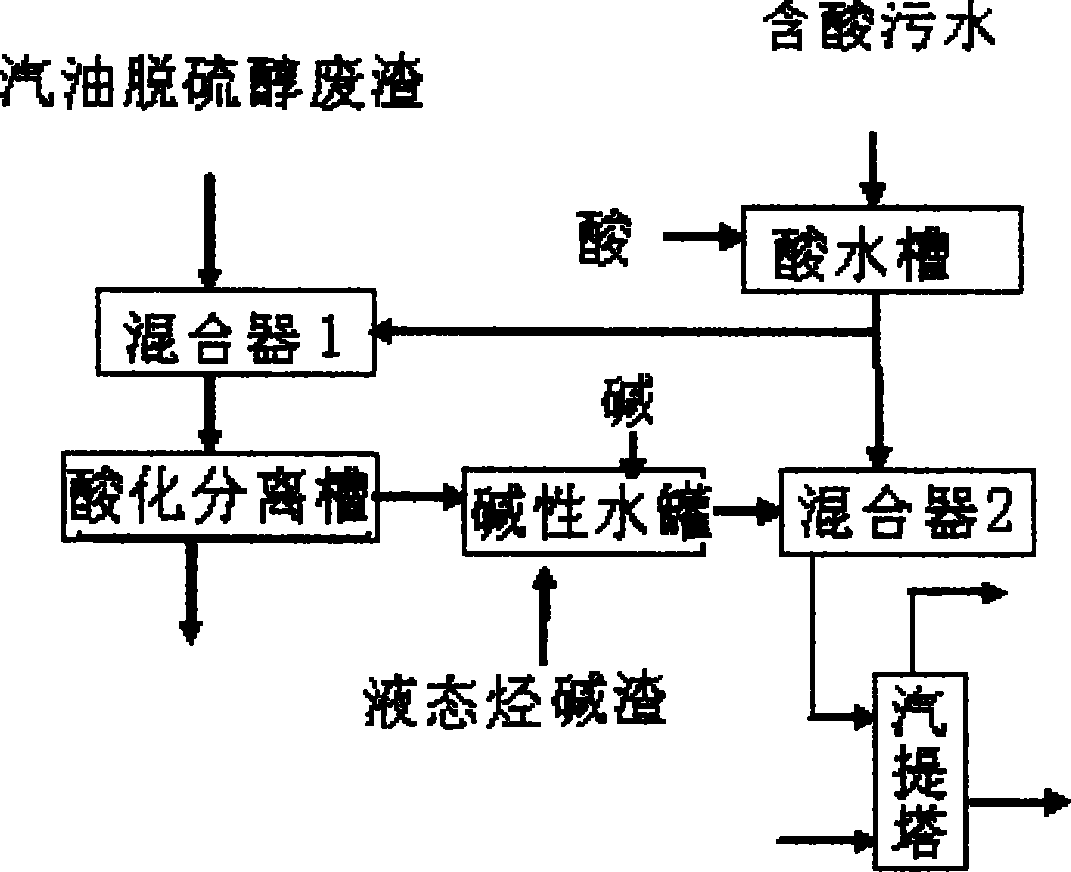

[0014] The equipment system and process are shown in the attached drawings. The system equipment consists of two online mixers, acidification separation tank or separation tower or centrifugal separator, acid water tank, alkaline water tank and stripping tower. The acid water tank is connected to the positive bed of the power station through the pump. The excess acid-containing sewage produced during backwashing is connected, and the acid water tank is connected to two online mixers respectively. The gasoline sweetening waste liquid residue is connected to the online mixer 1 through the pump, and the online mixer 1 is connected to the acidification separation tank. , the acidification separation tank is connected with the alkaline water tank, the alkaline water tank is respectively connected with the liquid hydrocarbon alkali residue and the online mixer 2, the online mixer 2 is connected with the stripper, and the stripper is connected with the sulfur plant and the sewage treat...

Embodiment 2

[0019] The equipment system and process are the same as in Example 1, and the operating conditions are: the acidification is carried out with excessive acid-containing sewage produced during backwashing of the positive bed, the acid content is 25.0% by weight of the acid-containing sewage, and the pH value of the acidification is 9.0.

[0020] Take 600ml of spent alkali residue, the pH value after acidification is 4.6, the residence time is 60min, and the clarification time is 80min. The COD removal rate of treated wastewater is 89.2%, and the oil removal rate is 92.5%.

Embodiment 3

[0022] The equipment system and process are the same as in Example 1, and the operating conditions are: the acidification is carried out with excessive acid-containing sewage produced during the backwashing of the positive bed, the acid content is 20% by weight of the acid-containing sewage, and the pH value of the acidification is 8.

[0023] Take 600ml of waste caustic residue, after acidification, the pH value is 6.8, the residence time is 90min, and the clarification time is 120min. After treatment, the COD removal rate of wastewater is 83.6%, and the oil removal rate is 90.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com