Double quality oscillatory type silicon micro-gyroscopes

A silicon micro-gyroscope and vibrating technology, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instrument and other directions, can solve the problems of limited sensitivity, poor linearity of angular vibration, etc., to increase flexibility and release heat Stress, the effect of improving the detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

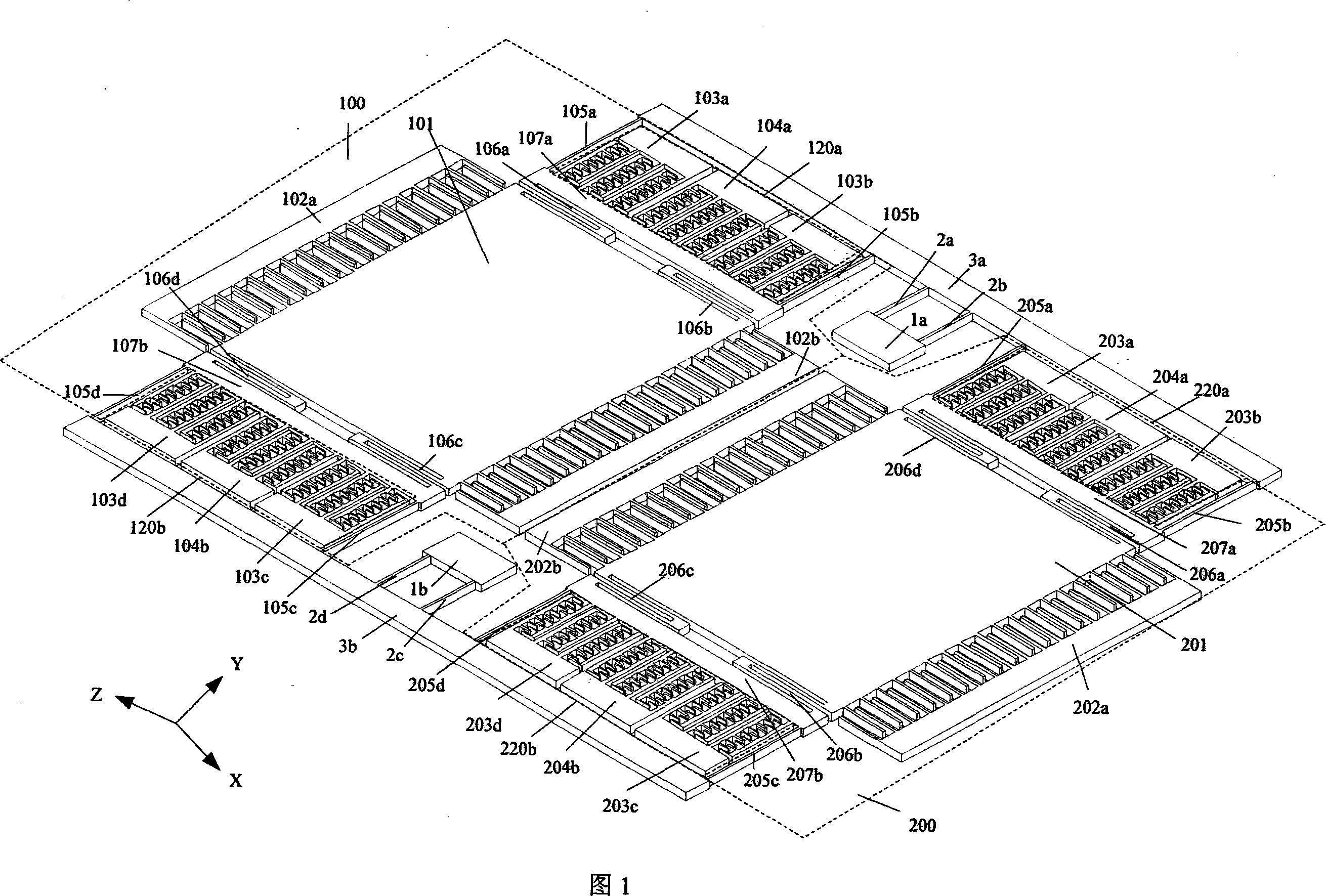

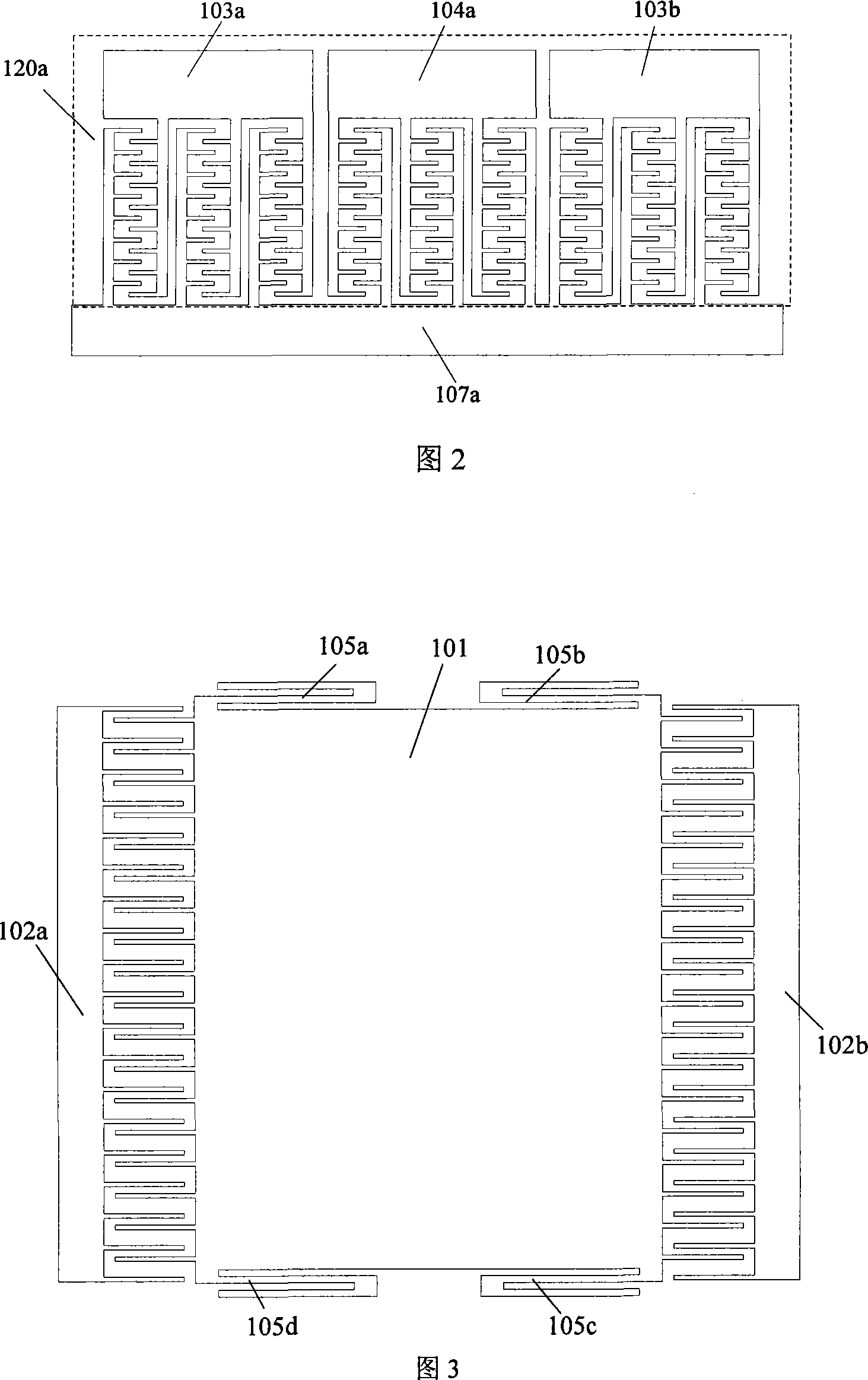

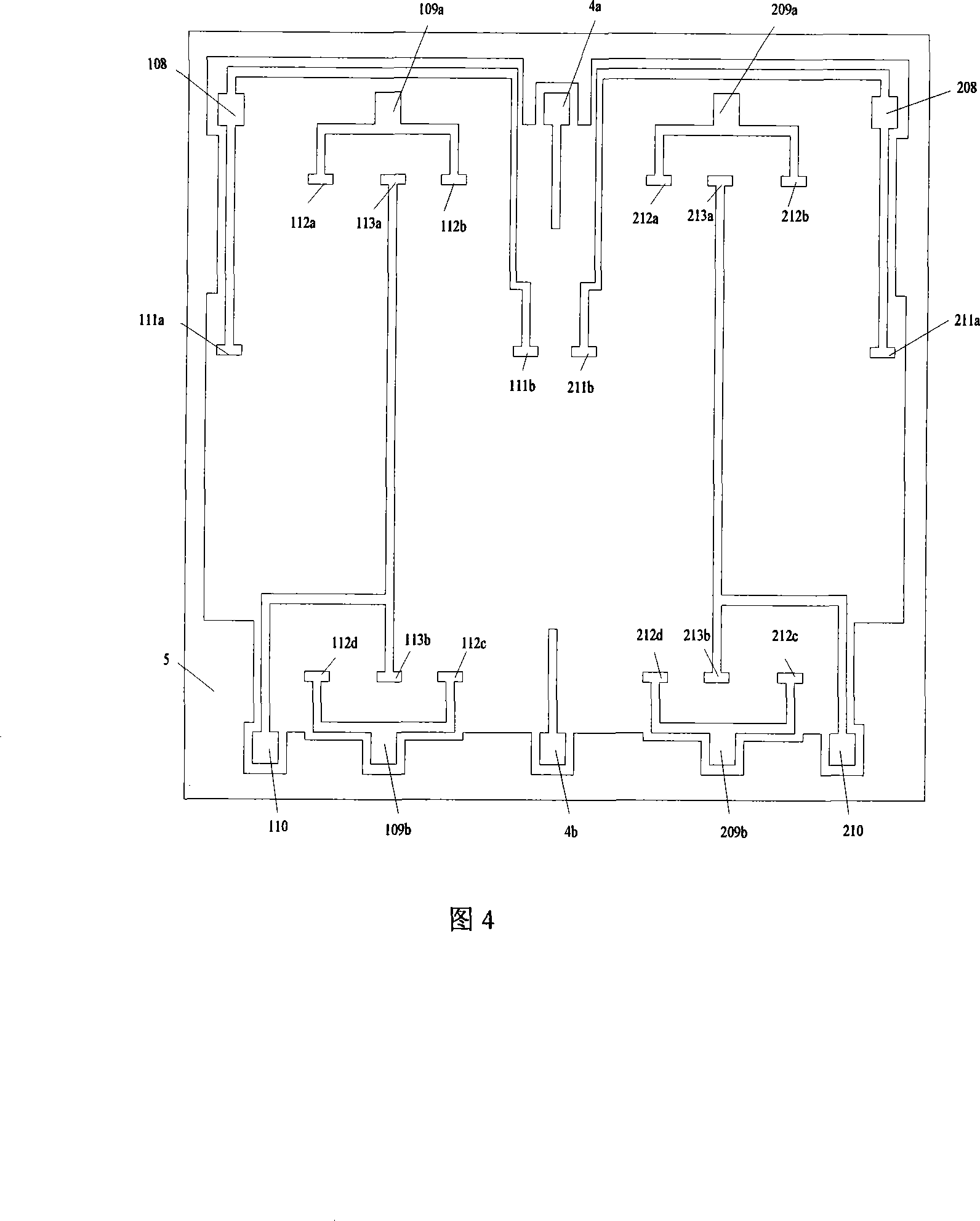

[0013] In conjunction with Fig. 1, the double-mass vibrating silicon micro-gyroscope of the present invention is used to measure a measuring instrument perpendicular to the base level, and consists of upper and lower layers, and the upper layer is a gyroscope mechanical structure made on a single-crystal silicon wafer. The lower layer is the signal leads made on the glass substrate. The upper mechanical structure of the gyroscope is composed of a pair of identical substructures 100, 200. The two substructures 100, 200 are arranged symmetrically on the left and right, and are respectively connected to the beams 3a, 3b. The beams 3a, 3b are connected to the fixed bases 1a, 1b through two groups of torsion bars 2a, 2b, 2c, 2d. The structure of the resonator 120a of the gyroscope is shown in Figure 2, and the resonator 210a consists of three groups of linear combs. Comb-like capacitors. Among them, the middle group is the drive feedback comb, which is composed of the fixed drive f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com