Automatic tuning control F-P fiber optic sensor

An optical fiber sensor and automatic tuning technology, applied in the field of optical fiber sensing, can solve problems such as expensive, weak light, and bulky systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

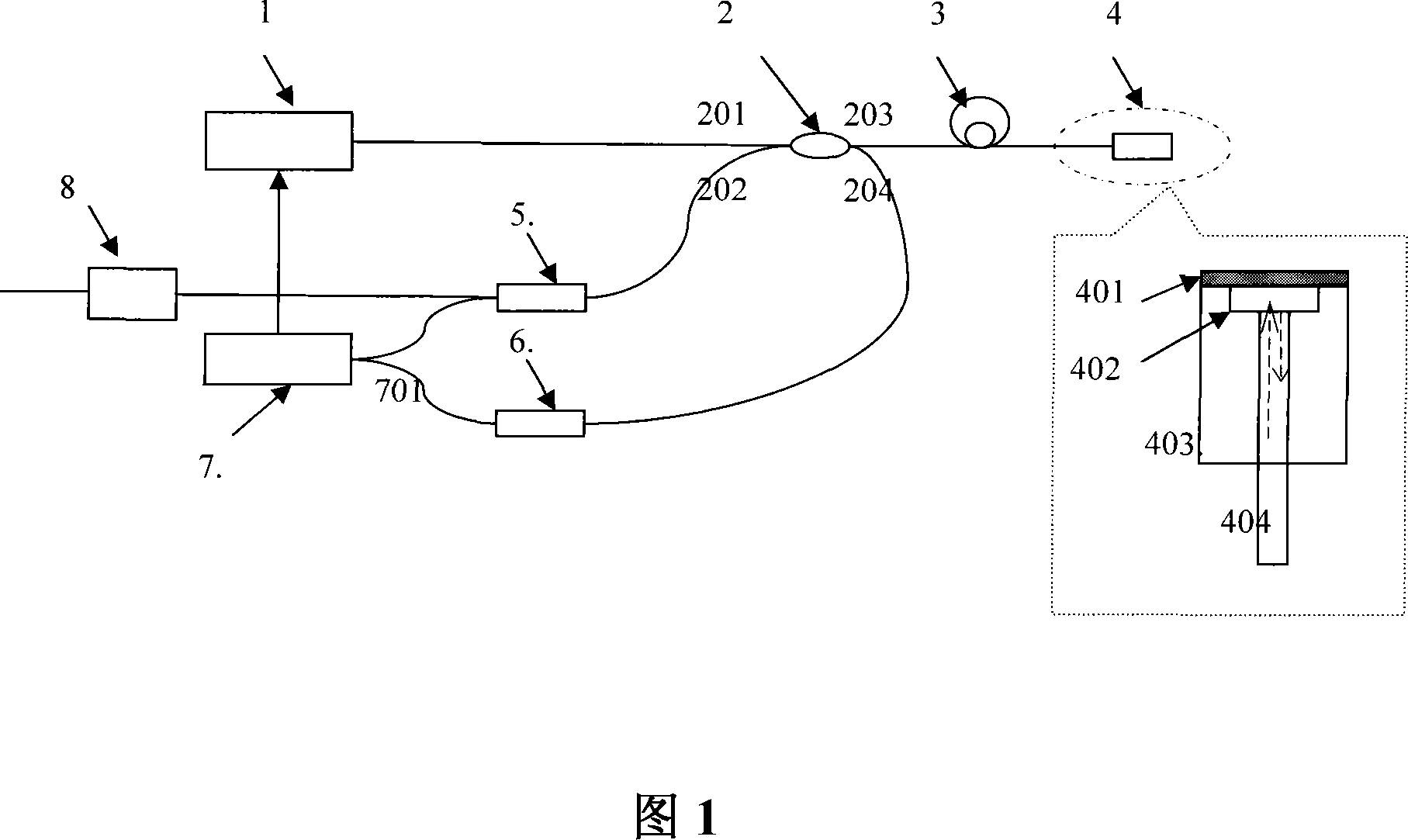

[0035]Please refer to Fig. 1 first. Fig. 1 is a schematic structural diagram of the automatic tuning F-P optical fiber sensor of the present invention, which is also a structural schematic diagram of an embodiment of the present invention. As can be seen from the figure, the automatic tuning F-P optical fiber sensor of this embodiment includes a light source 1 and a sensing head 4 , the light source 1 is a distributed feedback single-mode semiconductor laser with a temperature control circuit, the laser is connected to the first port 201 of the coupler 2 through an optical fiber, and the third port 203 of the coupler 2 is connected to the The sensing head 4, the fourth port 204 of the coupler 2 is connected to the active control unit 7 through the second photodetector 6, the second port 202 of the coupler 2 is connected to the input port of the first photodetector 5, The output end of the first photodetector 5 is respectively connected to the active control unit 7 and the signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com