Electrode active material and method for making same and lithium ion secondary battery electrode

A technology of electrode active materials and electrode materials, which is applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of not being able to increase the resistance in time and effectively cut off the current, and achieve easy industrial production and avoid The effect of fire or explosion and increased resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] According to one embodiment of the present invention, the composition containing conductive particles and crystalline polymers with positive temperature coefficient effects may also contain other materials with positive temperature coefficient effects, such as ceramic material particles with positive temperature coefficient effects such as Barium titanate and / or barium titanate particles embedded with Sr and Pb. Based on the total amount of the composition containing the conductive particles and the crystalline polymer with the positive temperature coefficient effect, the content of other materials with the positive temperature coefficient effect may be 0-20% by weight.

[0032] The electrode active material substrate can be various positive active material substrates or negative active material substrates conventionally used in lithium ion secondary batteries. For example, the positive active material substrate can be selected from lithium cobalt oxygen, lithium nickel ...

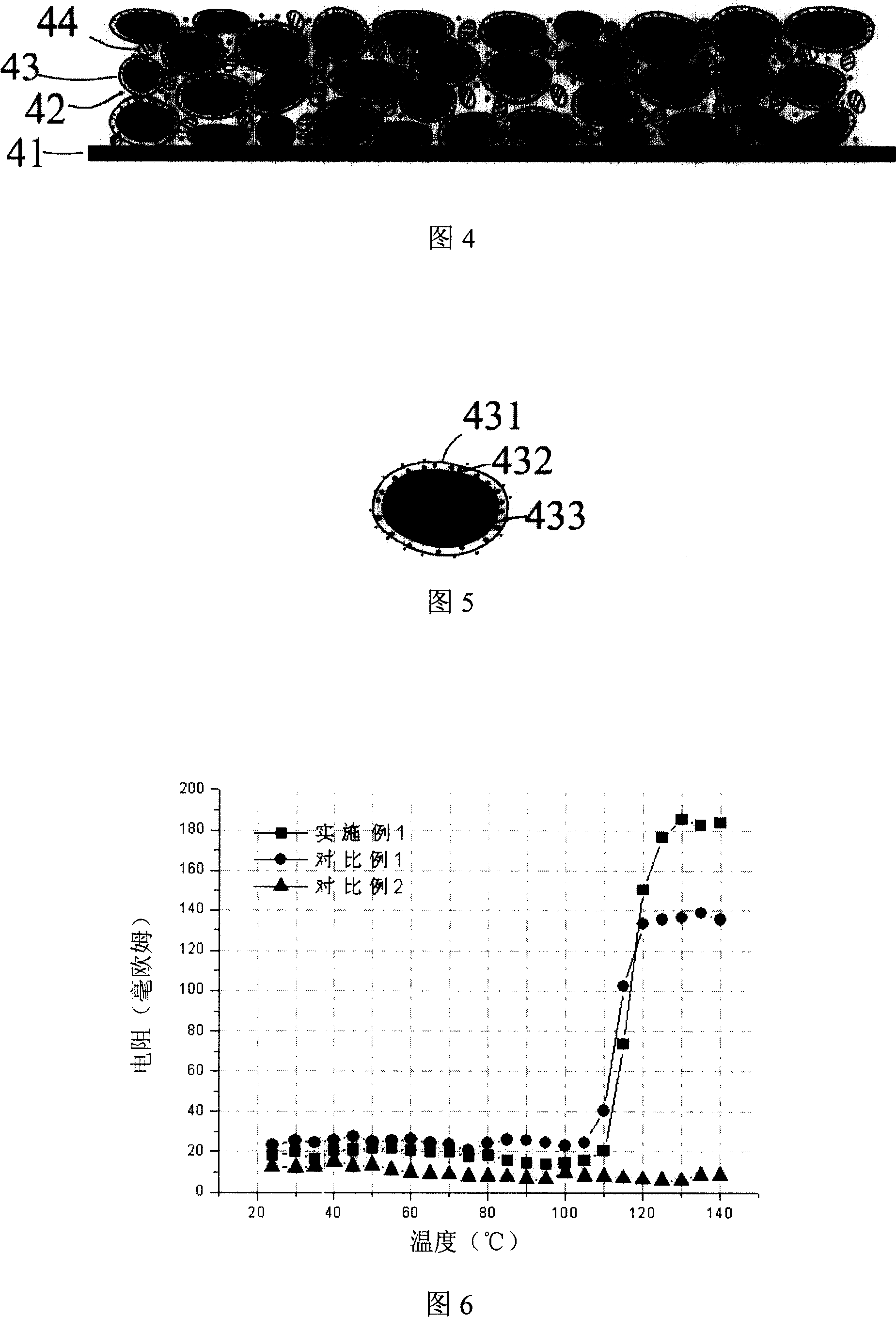

Embodiment 1

[0048] This embodiment is used to illustrate the electrode active material provided by the present invention, the electrode containing the material and the preparation method thereof.

[0049] Dissolve 3 grams of polyethylene with a glass transition temperature of 120°C and a crystallinity of 60% in 200 ml of hot xylene solvent at 80°C in a fume hood, and keep the temperature at 100°C under stirring until the polyethylene is completely dissolved After 1 gram of average particle diameter D 50 0.2 micron, resistivity 5×10 -5 Mix graphite with ohm cm and a specific surface of 350 square meters per gram and continue to stir evenly at this temperature. After stirring evenly, continue to heat to volatilize the solvent. The average particle diameter is D 50 9 micron cathode active material matrix LiCoO 2 Mix and stir vigorously until the solvent evaporates to polyethylene, graphite, LiCoO 2 After the mixture was coagulated, the coagulated product was placed in an oven at 130° C. ...

Embodiment 2-6

[0052] The examples 2-6 are used to illustrate the electrode active material provided by the present invention, the electrode containing the material and the preparation method thereof.

[0053] The electrode active material was prepared according to the method described in Example 1, except that the types and amounts of the raw materials of the electrode active material are shown in Table 1 below. In Table 1, the units of all dosages are grams, the units of glass transition temperature are °C, and the particle diameters are D 50 The unit of average particle diameter is micron, and the unit of resistivity is ohm·cm.

[0054] Then, according to the method described in Example 1, the electrode active material was prepared into an electrode sheet for a lithium ion secondary battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com