Grate-kiln pelletizing bed temperature field indirect monitoring method and device thereof

A technology of chain grate machine and temperature field, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc. Stability and other issues, to avoid large overshoot, overcome temperature fluctuations, and facilitate popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] First, select the thermocouple temperature sensor 2 according to the temperature to be measured. Because the temperature does not exceed 1000°C, select the nickel-chromium-nickel-silicon thermocouple temperature sensor 2.

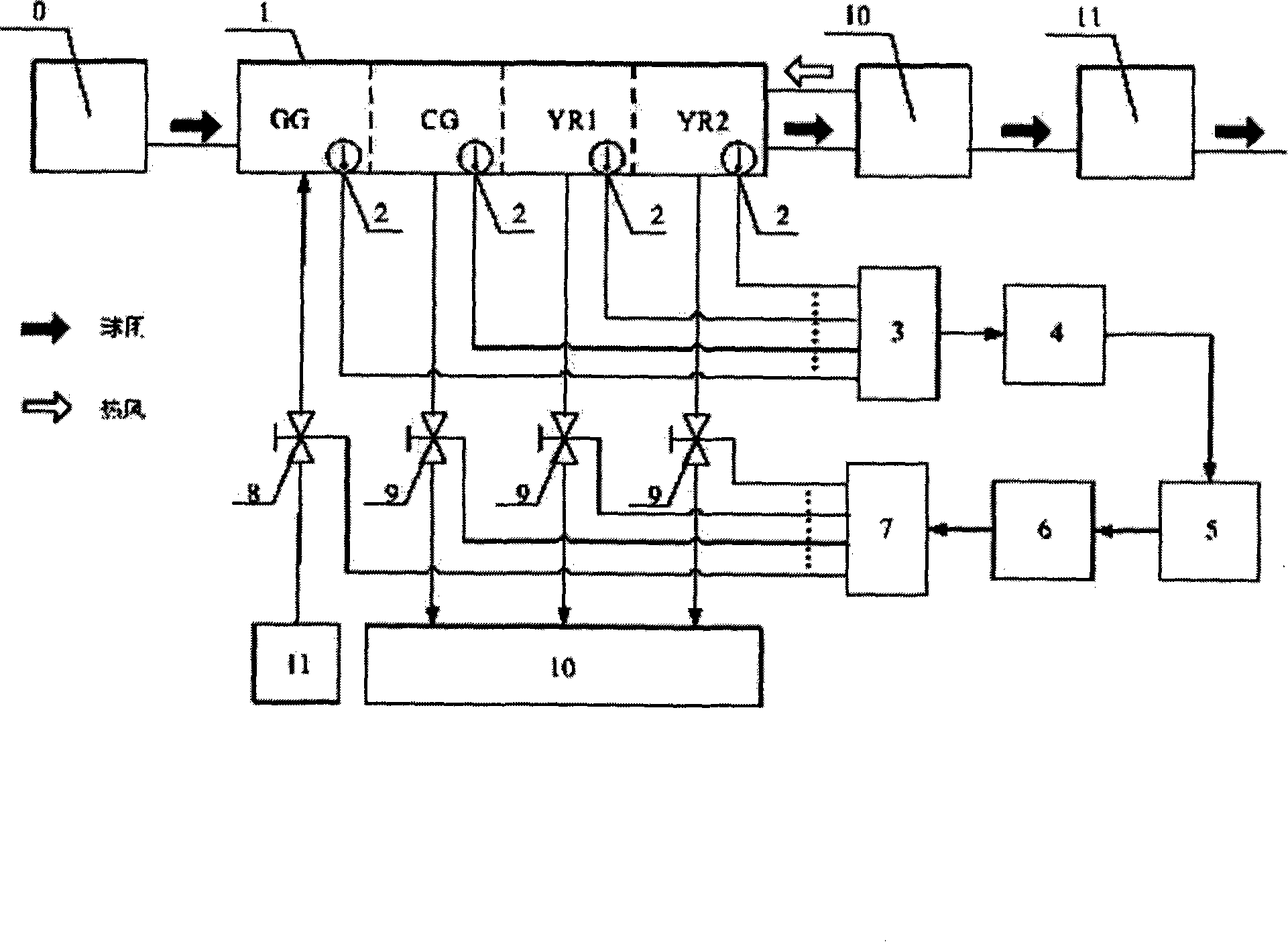

[0015] The second is the installation of the thermocouple temperature sensor 2. According to the working characteristics of the temperature field indirect measurement of the temperature field indirect monitoring and control device of the grate bed 1 of the pelletizing chain grate, it is to use the thermocouple temperature measuring sensor 2 to detect the drum of the pelletizing chain grate. The hot air temperature near the wind / suction air box is used to obtain the temperature field of the grate bed 1 of the pelletizing grate. For the blast drying section (GG) and the exhaust drying section (CG) on both sides of the 2.4 million tons of pellet grate, preheating 1 Section (YR1), preheating section 2 (YR2) has a total of 40 hot air blast / extraction air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com