Method for producing pasteable polymers

A polymer and unsaturated technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve problems such as adverse effects on performance, and achieve the effect of avoiding complicated preparation and shortening the time of metering and adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

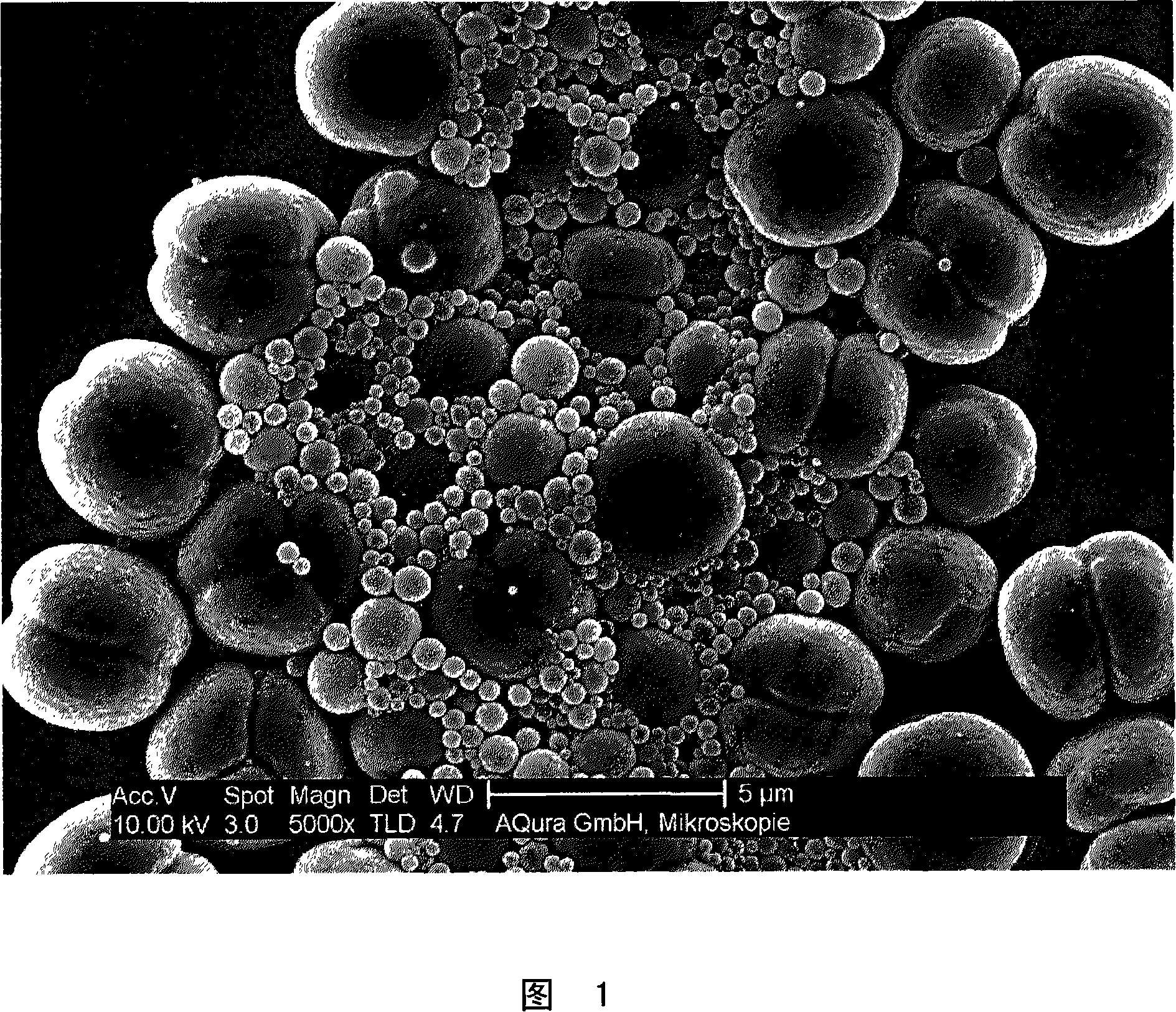

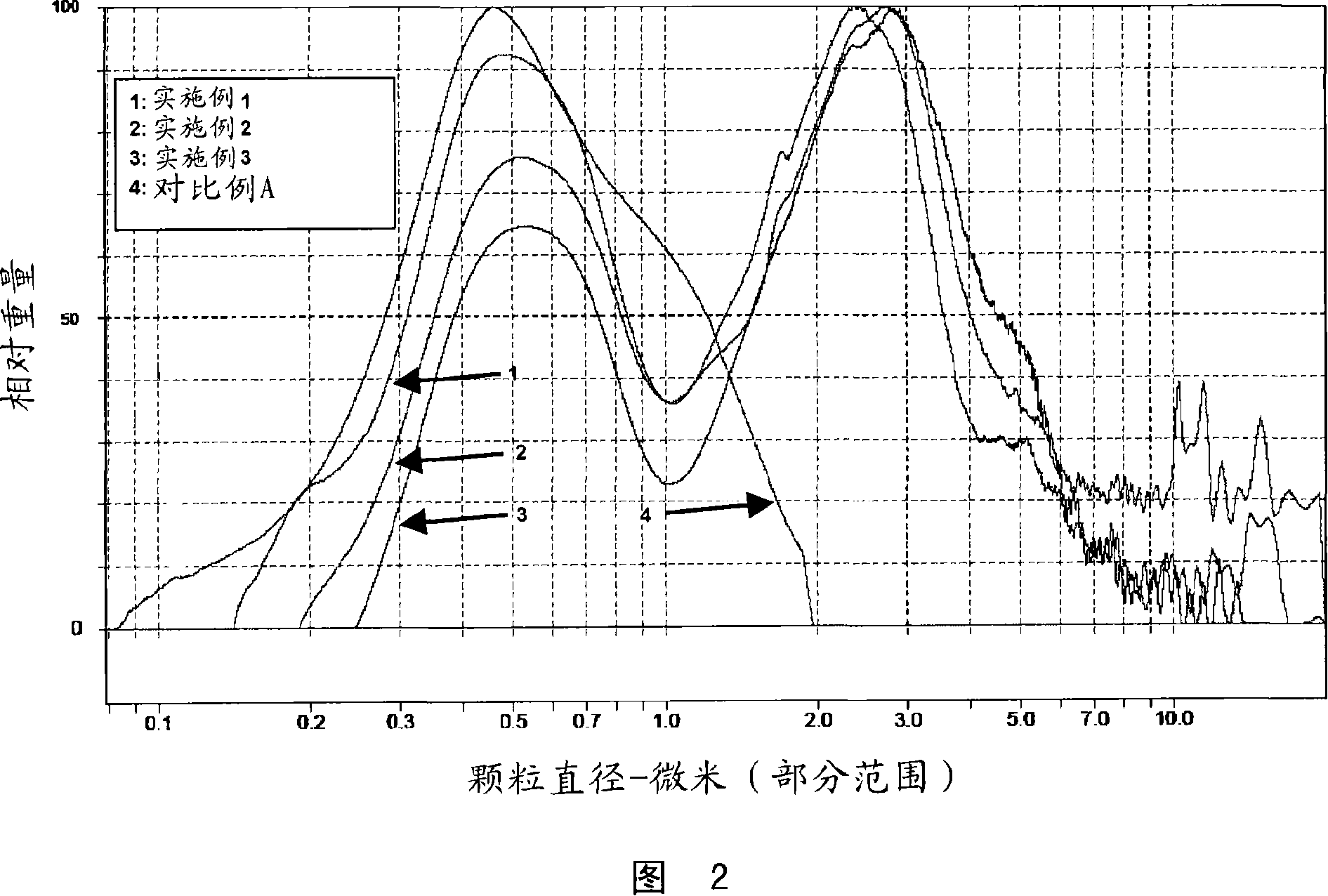

Image

Examples

Embodiment 1

[0049] 4400kg deionized water was added to the 15m3 stirred tank as an initial charge. Then add the following materials to it

[0050] 55kg alkyl aryl sulfonate

[0051] 55kg octadecyl monoethylene glycol ether

[0052] 5.5kg dimyristyl peroxydicarbonate

[0053] 5500kg vinyl chloride

[0054] The mixture was stirred at 25 °C for 15 min and then pressed through a rotor-stator-disperser with 10.5 bar and 0.5 mm gap width into 15 m 3 Stir in the kettle. The dispersion time here is 36min, and the throughput is 18m 3 / h.

[0055] The reaction mixture was heated in an autoclave to a polymerization temperature of 52°C. The polymerization time is about 8h.

[0056] After removal of the monomers, the dispersion is processed by means of spray drying to produce polyvinyl chloride powder. The spray-drying conditions are adjusted so that the particle size distribution of the powder meets the requirement of <1 wt% of particles larger than 63 μm.

[0057] To determine the rheologi...

Embodiment 2

[0059] 4400kg deionized water was added as an initial charge to the 15m 3 Stir in the kettle. Then add the following materials to it

[0060] 35kg alkyl aryl sulfonate

[0061] 35kg octadecyl monoglycol ether

[0062] 5.5kg dimyristyl peroxydicarbonate

[0063] 5500kg vinyl chloride

[0064] The mixture was stirred for 15 min at 25 °C and then pressed through a rotor-stator-disperser with 10.5 bar and 0.5 mm gap width into 15 m 3 Stir in the kettle. The dispersion time here is 36min, and the throughput is 18m 3 / h.

[0065] The reaction mixture was heated in an autoclave to a polymerization temperature of 52°C. The polymerization time is about 8h.

[0066] The dispersion was processed as in Example 1. The paste viscosities of the powders are reported in Table 1.

Embodiment 3

[0068] 4400kg deionized water was added as an initial charge to the 15m 3 Stir in the kettle. Then add the following materials to it

[0069] 35kg alkyl aryl sulfonate

[0070] 35kg octadecyl monoglycol ether

[0071] 5.5kg dimyristyl peroxydicarbonate

[0072] 3000kg vinyl chloride

[0073] The mixture was stirred for 15 min at 25 °C and then pressed through a rotor-stator-disperser with 10.5 bar and 0.5 mm gap width into 15 m 3 Stir in the kettle. The dispersion time here is 30min, and the throughput is 18m 3 / h. 2500 kg of vinyl chloride was fed into the stirred tank and the reaction mixture was subsequently heated.

[0074] The reaction mixture was heated in an autoclave to a polymerization temperature of 52°C. The polymerization time is about 8h.

[0075] The dispersion was processed as in Example 1. The paste viscosities of the powders are reported in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com