Hydraulic power system for bus

A technology of hydraulic power system and hydraulic power device, which is applied in the field of bus hydraulic power system, can solve the problems of low power, pollute urban air environment, increase fuel consumption, etc., and achieve the effects of low noise, low energy consumption and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

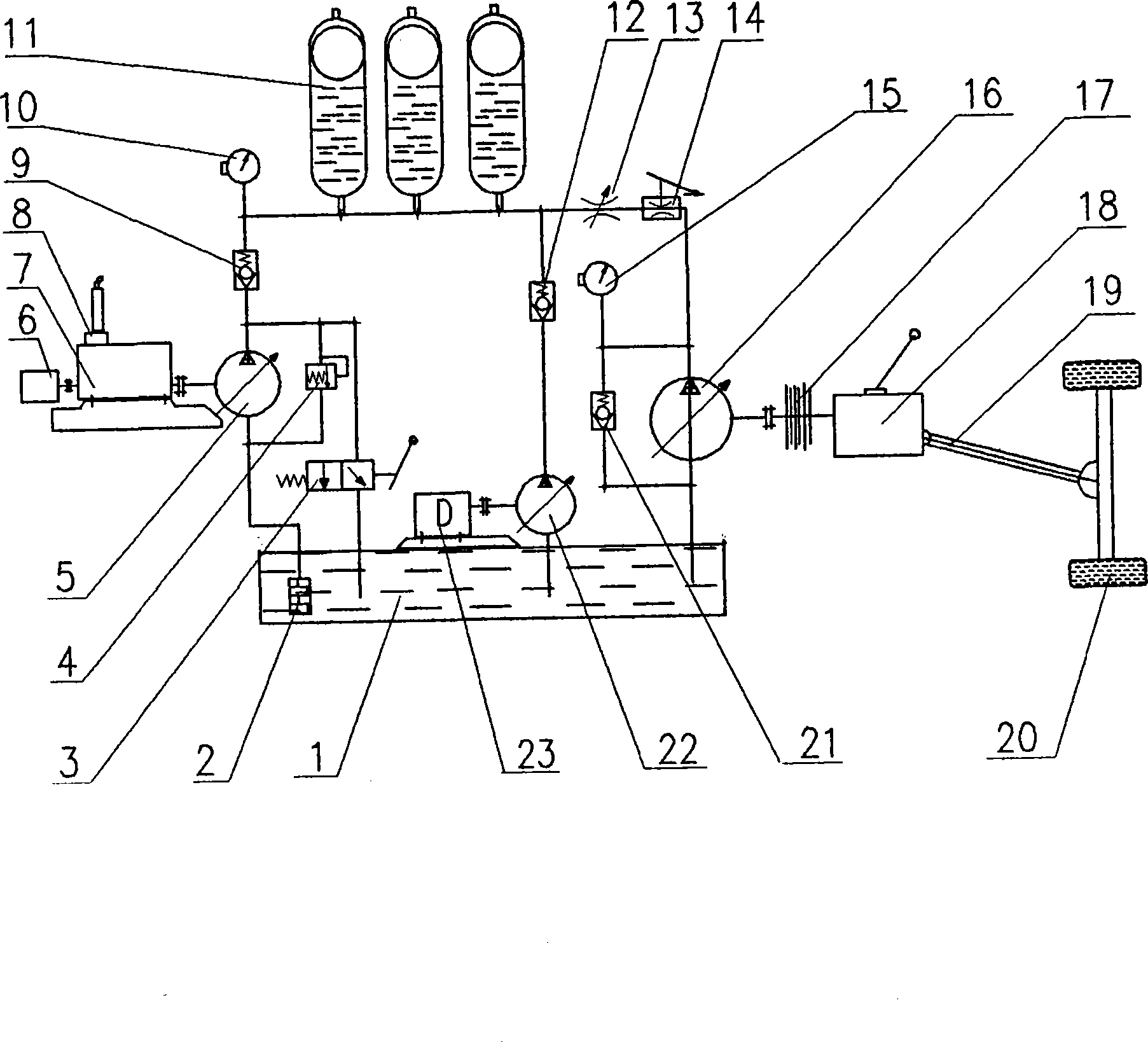

[0011] With reference to accompanying drawing, the bus hydraulic power system of the present invention, it is formed a power output system by the hydraulic power unit of small-sized diesel engine 7 and electric hydraulic power unit, connects dc generator 6 and exhaust gas turbocharger 8 on the small-sized diesel engine 7 With variable flow hydraulic pump 5 and one-way valve 9, the variable flow hydraulic pump 5 is connected with overflow safety valve 4 and manual pressure relief valve 3, hydraulic oil filter 2, hydraulic oil tank 1, and multiple hydraulic oil accumulators 11. The pipeline is connected with a pressure display instrument 10 with a pressure switch, a flow limiting valve 13 and a pedal flow proportional control compound valve 14. The pipeline of the high-speed high-torque hydraulic motor 16 is connected with the pedal flow proportional control compound valve 14. High-speed and high-torque The clutch 17 is connected between the hydraulic motor 16 and the gearbox 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com