Non-contact feeding device for elevator car

A non-contact, feeding device technology, applied in the direction of circuits, inductors, electrical components, etc., can solve the problems of complex manufacturing process and high price, and achieve the effects of low equipment cost, increased power, and excellent power transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be described below with reference to the drawings.

[0056] 1st embodiment

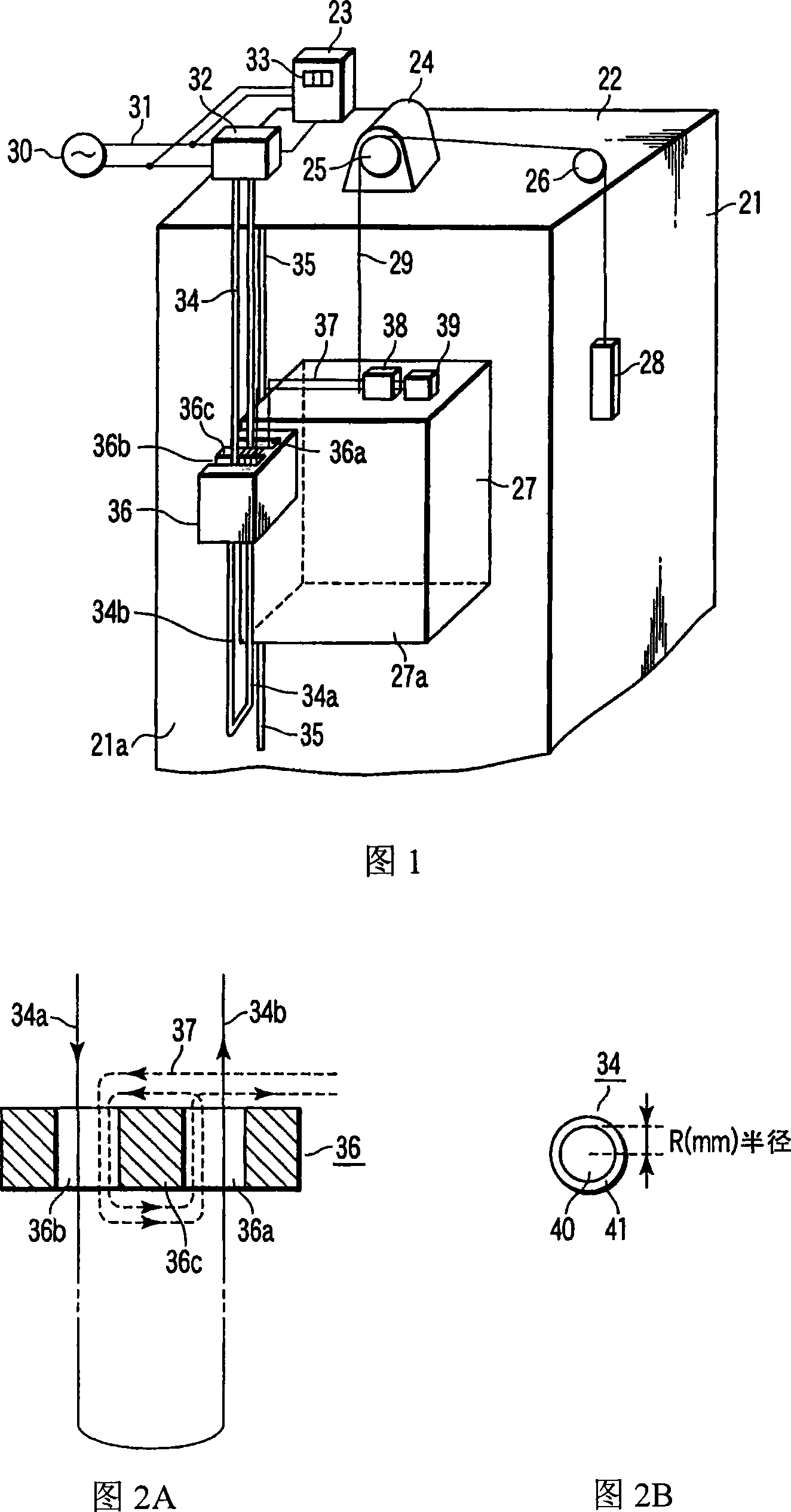

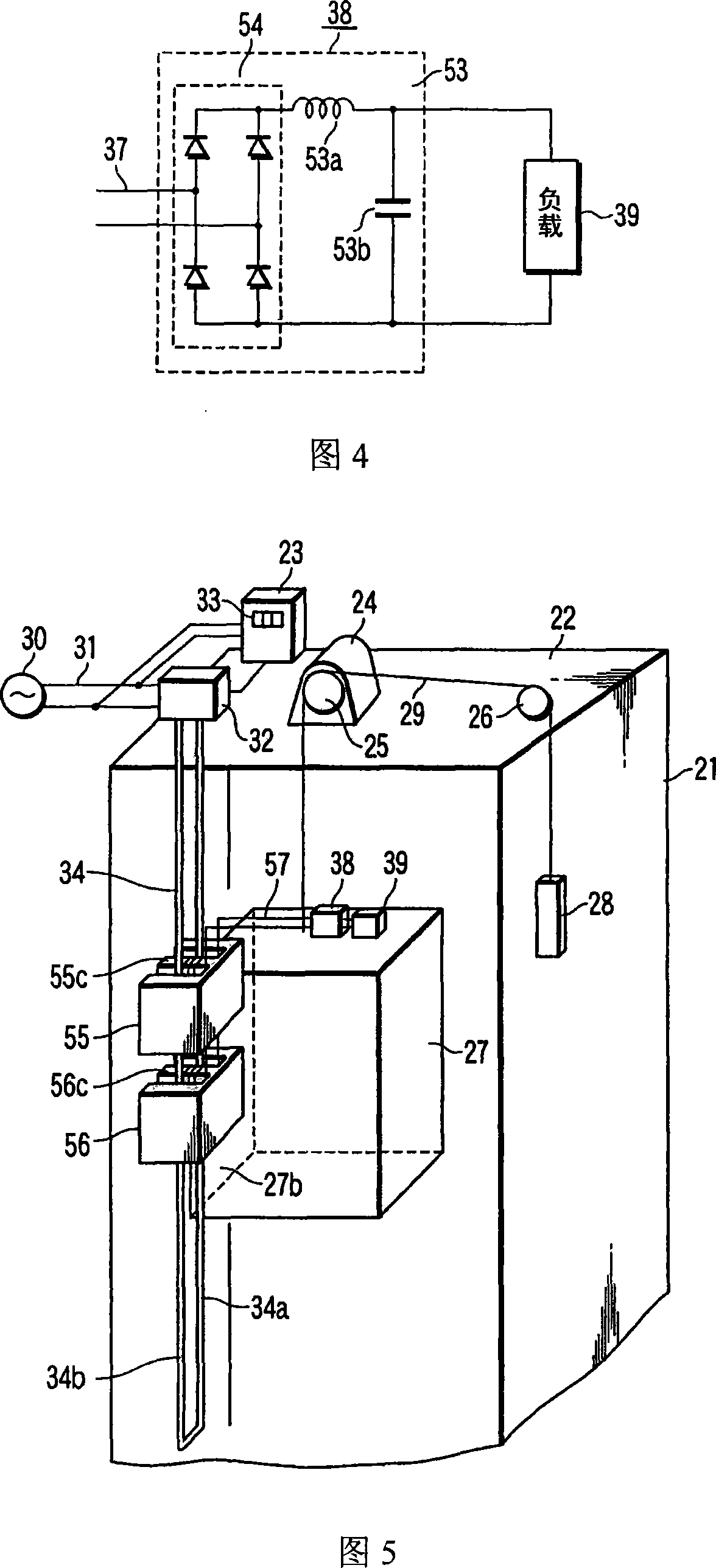

[0057] Fig. 1 is a schematic diagram showing a main part of an elevator system incorporating a non-contact power feeding device for an elevator car according to a first embodiment of the present invention.

[0058] A control panel 23 and a hoist 24 are installed in a machine room 22 provided above an elevator passageway 21 formed in a building such as a building. On the main pulley 25 and deflector pulley 26 of hoisting machine 24, car 27 is installed at one end, and the main cable 29 of balance weight 28 is installed on the other end.

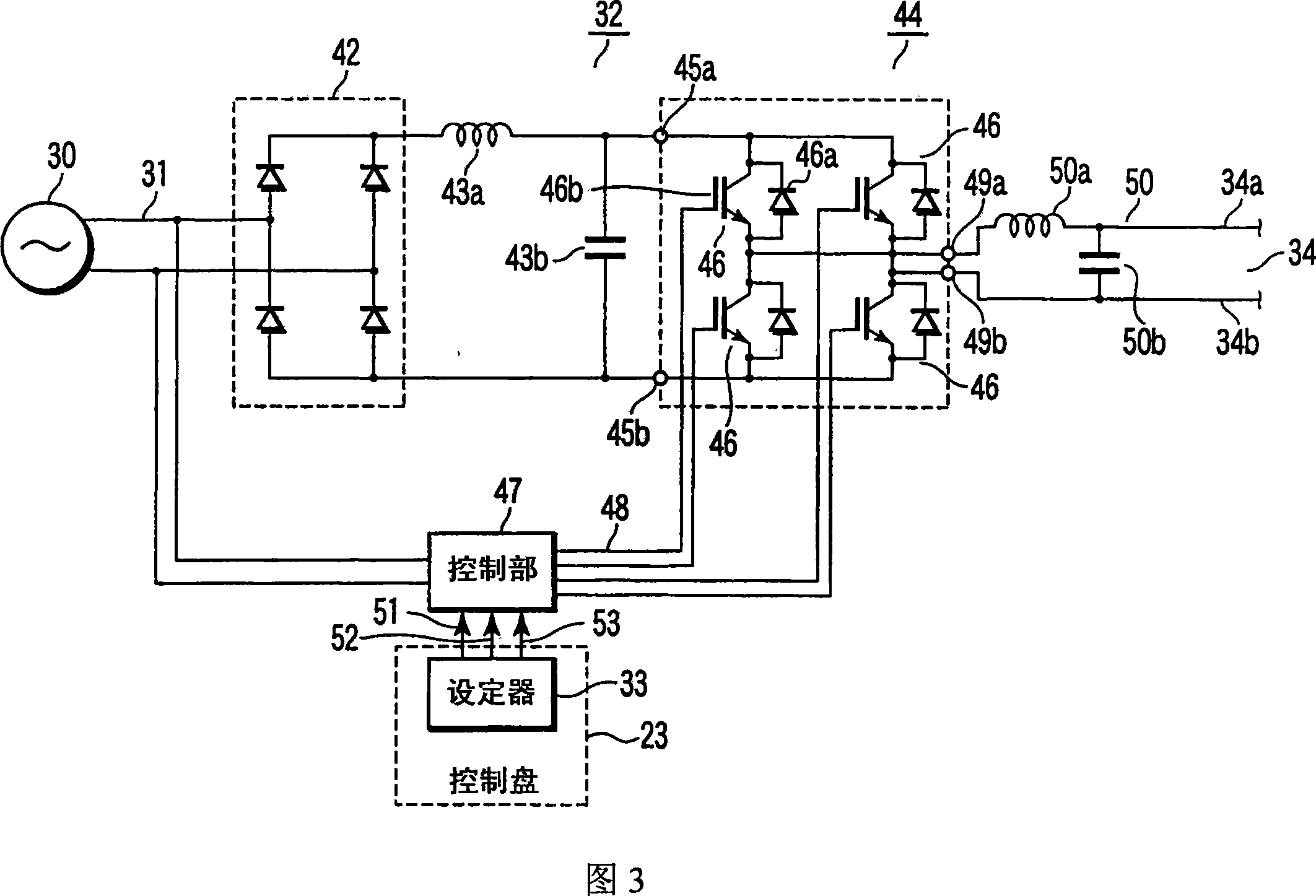

[0059] A motor drive circuit for driving the motor in the hoist 24 is installed in the control panel 23 that supplies single-phase AC power from an external single-phase commercial power supply 30 through a power cable 31 . And in the control panel 23, an operation control unit is installed, and the operation control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com