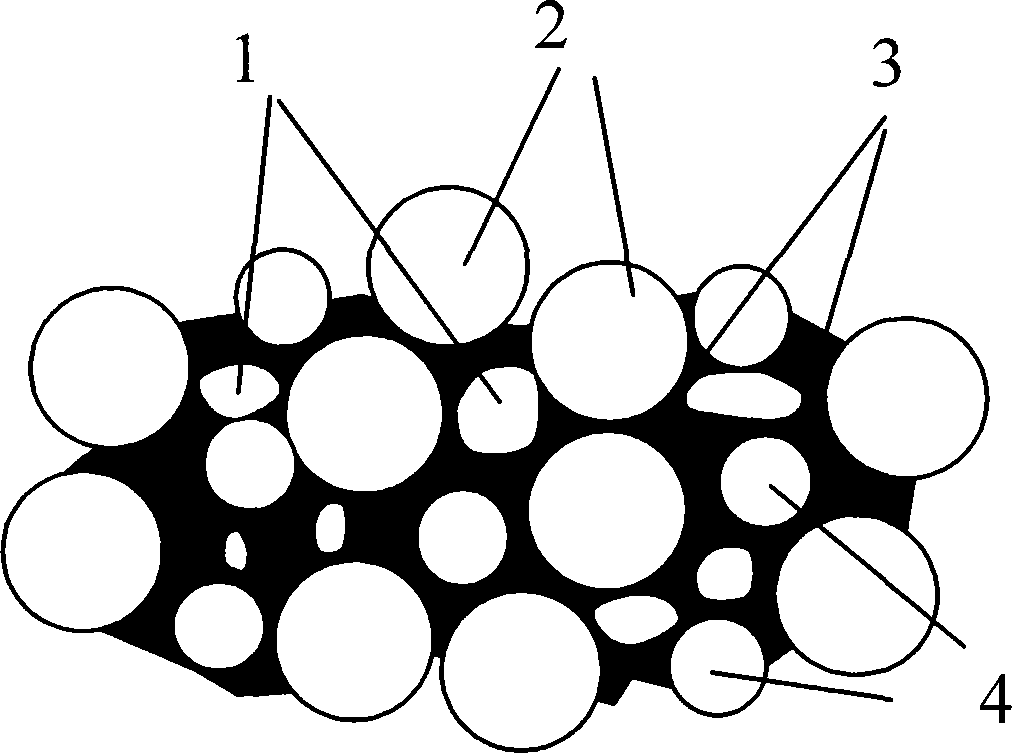

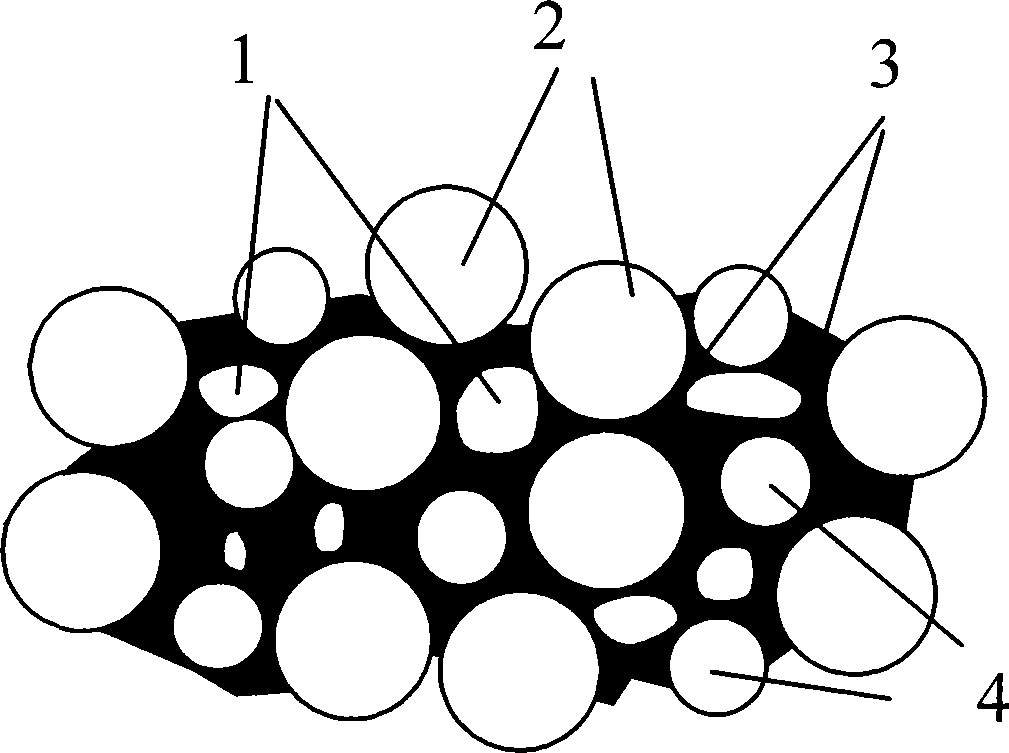

Multi-level grain size abrasive grain mixed semi-fixation abrasive grain grinding tool

An abrasive particle and particle size technology, applied in the field of semi-fixed abrasive abrasive tools, can solve the problem of inability to take into account the processing accuracy and processing efficiency, and achieve the effect of improving material removal efficiency, improving processing efficiency and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The abrasive grains of the present embodiment are 1000# and 3000# silicon carbide abrasive grains; the adhesive is a plant gum adhesive, such as sodium alginate, galactose, gum arabic; the additive is a silicone oil waterproofing agent and an aluminum powder filler; each component The mass percentage is: the total weight of the abrasive tool is 2.5 kg, 1000# and 3000# silicon carbide abrasive grains account for 70% of the total mass, the ratio is 1000#:3000#=7:3, vegetable adhesive 15%, silicone oil waterproofing agent 7%, aluminum powder filler 8%.

Embodiment 2

[0036] The abrasive grains of the present embodiment are 1000# and 2000# alumina abrasive grains; the adhesive is a starch adhesive, such as potato starch and cornstarch; the additive is a silicon latex water repellant and a tributyl phosphate defoamer; each component The mass percentage is: the total weight of the abrasive tool is 2 kg, the 1000# and 2000# alumina abrasive grains account for 82% of the total mass, the ratio is 1000#:2000#=9:1, the starch adhesive is 6.6%, and the silicon latex waterproofing agent 5%, tributyl phosphate defoamer 0.4%.

Embodiment 3

[0038] The abrasive grains of this embodiment are 600# and 2000# boron carbide abrasive grains; the adhesive is a natural polymer adhesive, such as gelatin and casein; the additive is a silicon latex waterproofing agent; the mass percentage of each component is: It weighs 1.8 kg, 600# and 2000# boron carbide abrasive grains account for 94% of the total mass, the ratio is 600#:2000#=3:7, natural polymer adhesive is 1%, and silicon latex waterproofing agent is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com