Device for calcining aluminum oxide clinker by directly utilizing coal powder and method thereof

A technology of calcining alumina and clinker, which is applied in the direction of alumina/hydroxide preparation, etc., can solve the problems of land and water pollution, pollution, environmental pollution, etc., achieve low energy consumption and high-efficiency collection, increase reaction speed, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

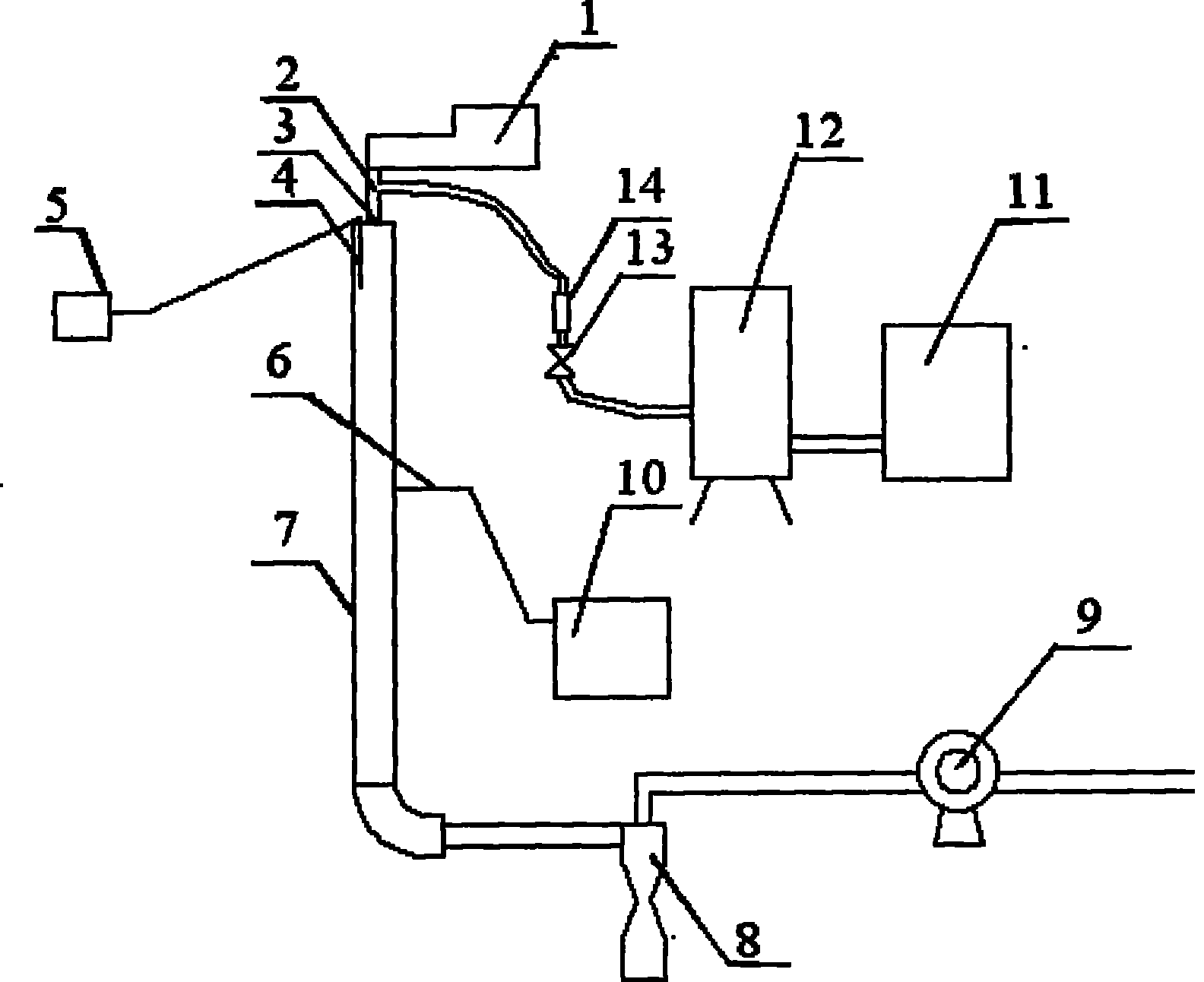

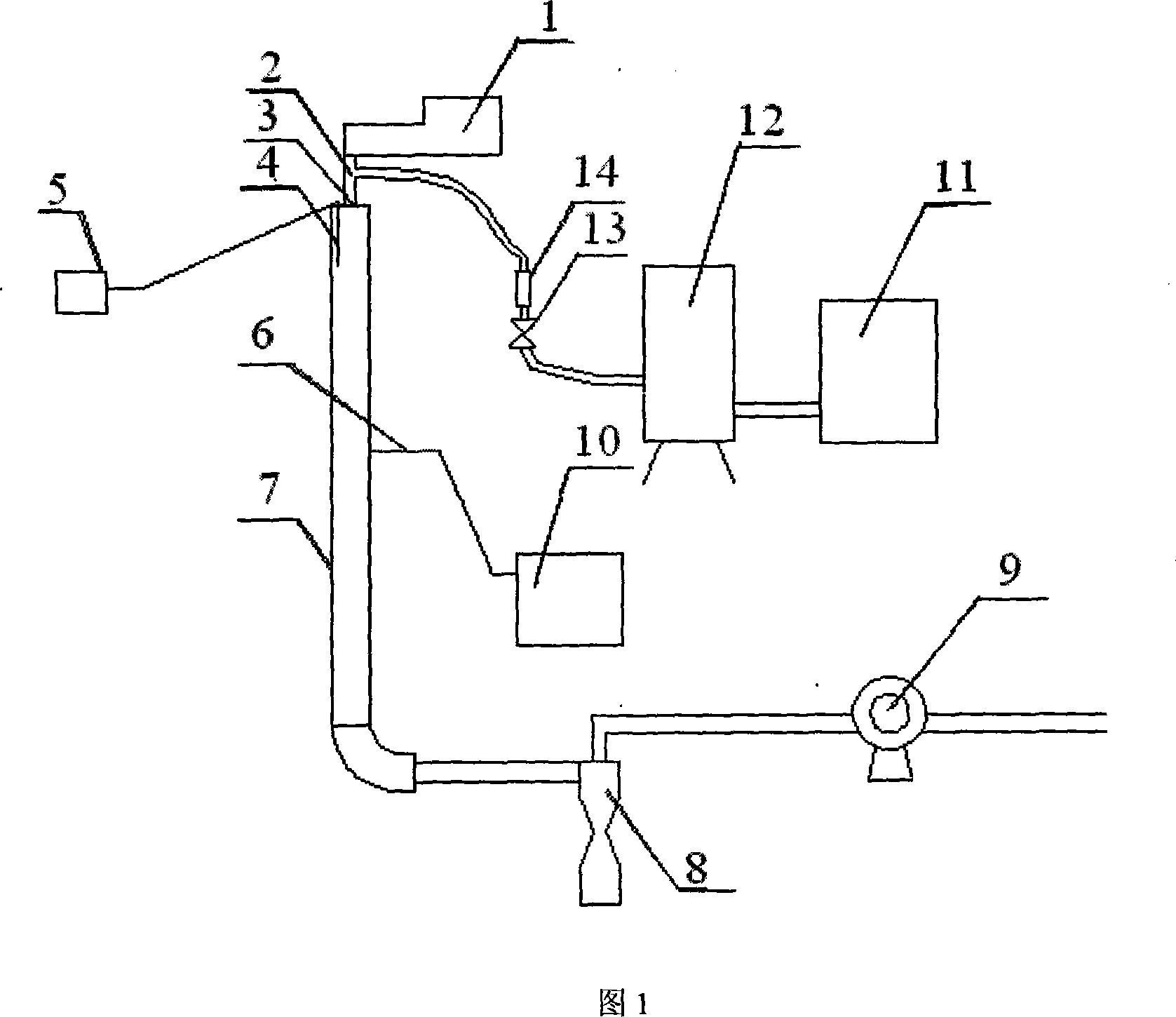

Method used

Image

Examples

Embodiment 1

[0047] 1. Select the high-alumina raw coal from the Zhungeer area of Inner Mongolia. The alumina content in the fly ash after normal combustion is 50%, and the ash content is 10%. The local limestone in Xi'an is selected, and the purity of calcium oxide is >90%. Ratio of high alumina coal to limestone: 8:2.

[0048] 2. Use ordinary ball milling method to crush, the ball milling speed is 150 rpm, and the ball milling is continued for 1 hour to prepare powder with an average particle size of less than 100 microns.

[0049] 3. The uniform powder feeding rate of the screw feeder is 300g / min, and the compressed air volume is 0.3m 3 / minute.

[0050] 4. The design height of the furnace is 3 meters, so that the residence time of the coal ash powder in the furnace is 1 second, and the temperature of the furnace is controlled at 1250 ° C to 1300 ° C.

[0051] 5. The fly ash collection device is a cyclone separation and cloth bag separation and an integrated collection device. This...

Embodiment 2

[0053] The difference between this example and Example 1 is that the ratio of high-alumina coal to limestone is 7:3, the mass ratio of the obtained alumina clinker to calcium aluminate reaches 20% to 24%, and the actual conversion rate of alumina clinker reaches 90%. %above.

Embodiment 3

[0055] The difference between this example and Example 1 is that the ratio of high-alumina coal to limestone is 5:5, the mass ratio of calcium aluminate in the obtained alumina clinker reaches 16% to 20%, and the actual conversion rate of alumina clinker reaches 90%. %above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com