Borate red and green fluorophor and preparation method thereof

A green fluorescence and borate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems that the performance cannot meet the development of science and technology, and achieve the effect of cheap raw materials, good process repeatability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

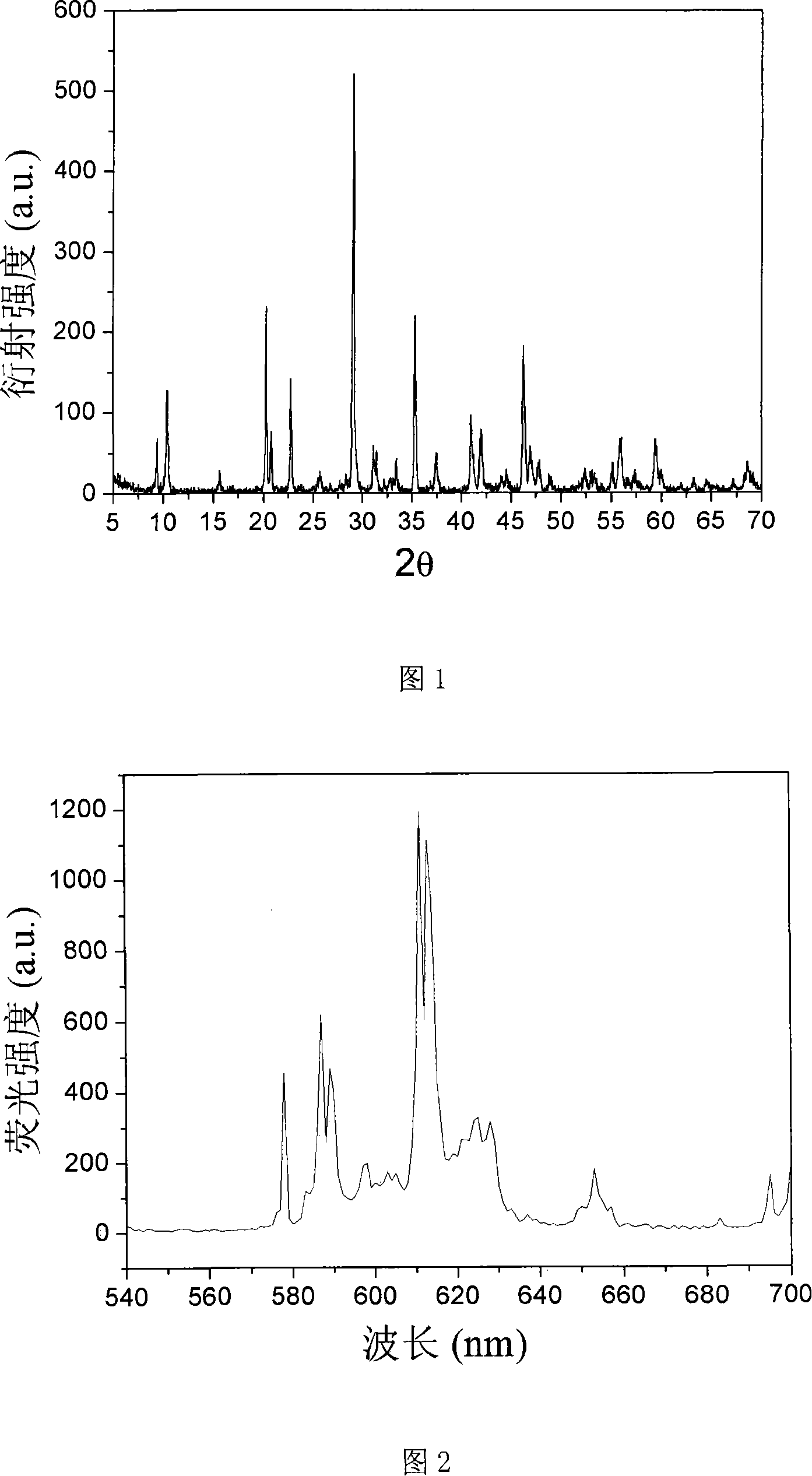

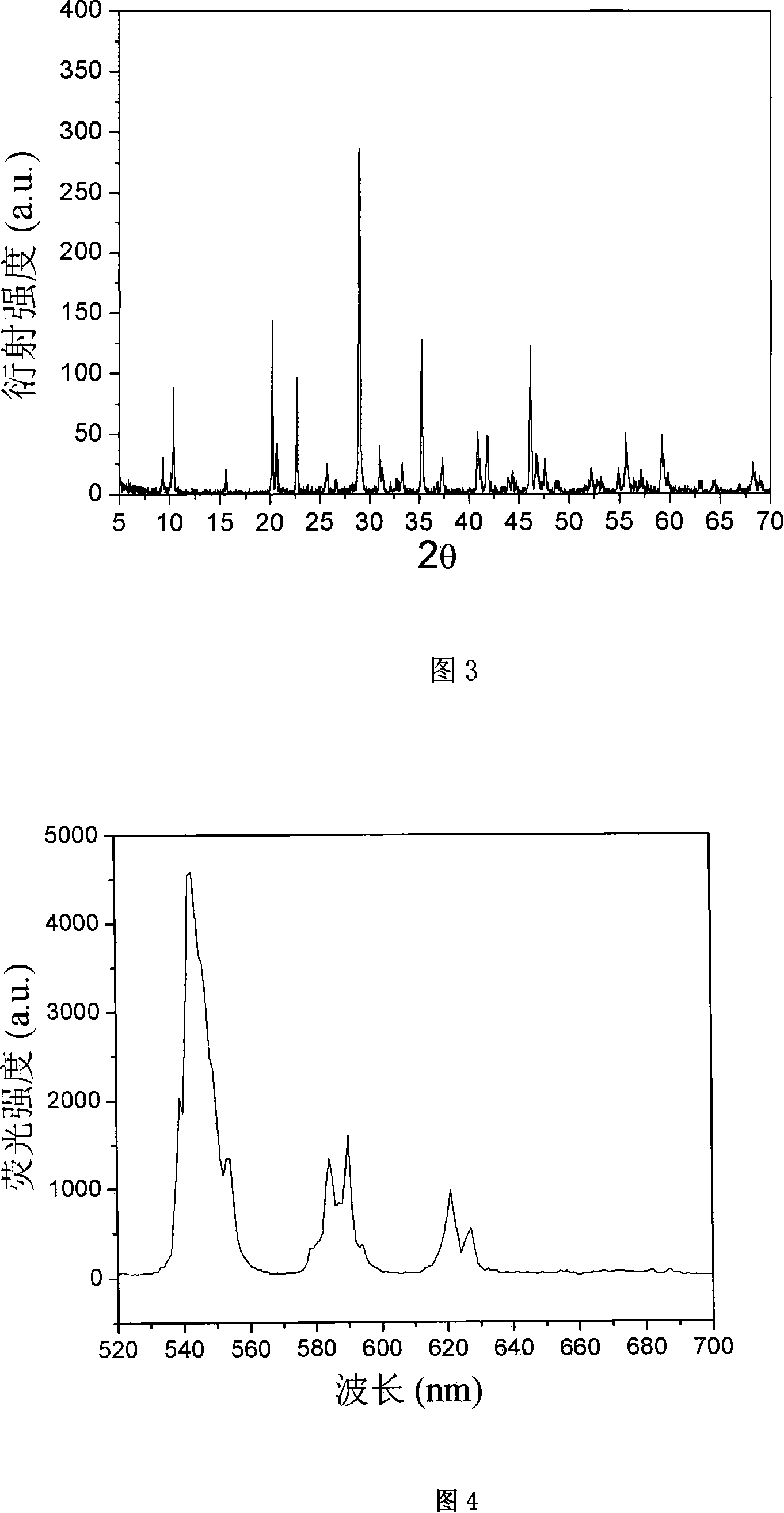

[0029] According to the molar ratio of B:Na:La:Ln=8:3:8.91:0.09, respectively weigh two groups of compound samples containing B, Na, La, Ln: Na 2 CO 3 、H 3 BO 3 , La 2 o 3 , Tb 4 o 7 and Na 2 CO 3 、H 3 BO 3 , La 2 o 3 、Eu 2 o 3 , weigh Li according to 2% of the total mass of the respective compounds 2 CO 3 , and then grind and mix the two groups of materials separately, put them in two corundum crucibles, pre-fire at 200°C for 5 hours, take out the furnace charge after cooling, and then sinter at 950°C for 1 hour, cool the product to room temperature, grind, Respectively, the composition is Na 3 La 8.55 Tb 0.45 B 8 o 27 and Na 3 La 8.55 Eu0.45 B 8 o 27 of phosphors. Na 3 La 8.55 Tb 0.45 B 8 o 27 Phosphor emits bright green light under the excitation of 264nm and 365nm ultraviolet light, Na 3 La 8.55 Eu 0.45 B 8 o 27 The phosphor emits bright red light under the excitation of 264nm and 365nm ultraviolet light. Figure 1 is Na 3 La 8.55 Eu 0...

Embodiment 2

[0031] According to the molar ratio of B:Na:La:Ln=8:3:5.49:3.51, respectively weigh two groups of compound samples containing B, Na, La, Ln: Na 2 CO 3 、H 3 BO 3 、La 2 o 3 , Tb 4 o 7 and Na 2 CO 3 、H 3 BO 3 、La 2 o 3 、Eu 2 o 3 , weigh Li according to 30% of the total mass of the respective compounds 2 CO 3 , and then grind and mix the two groups of materials separately, place them in two corundum crucibles, pre-fire at 600°C for 2 hours, take out the furnace material after cooling, and then sinter at 800°C for 48 hours. The product is cooled to room temperature and ground. Respectively, the composition is Na 3 La 8.55 Tb 0.45 B 8 o 27 and Na 3 La 8.55 Eu 0.45 B 8 o 27 of phosphors. Na 3 La 8.55 Tb 0.45 B 8 o 27 Phosphor emits bright green light under the excitation of 264nm and 365nm ultraviolet light, Na 3 La 8.55 Eu 0.45 B 8 o 27 The phosphor emits bright red light under the excitation of 264nm and 365nm ultraviolet light.

Embodiment 3

[0033] According to the molar ratio of B:Na:La:Ln=8:3:7.2:1.8, respectively weigh two groups of compound samples containing B, Na, La, Ln: Na 2 CO 3 、H 3 BO 3 、La 2 o 3 , Tb 4 o 7 and Na 2 CO 3 、H 3 BO 3 、La 2 o 3 、Eu 2 o 3 , Weigh Li according to 14% of the total mass of the respective compounds 2 CO 3 , and then grind and mix the two groups of materials separately, put them in two corundum crucibles, pre-fire at 400 °C for 3.5 hours, take out the furnace material after cooling, wash with deionized water, filter, dry, and then heat at 900 °C After sintering for 24 hours, the product was cooled to room temperature and ground to obtain the composition Na 3 La 8.55 Tb 0.45 B 8 o 27 and Na 3 La 8.55 Eu 0.45 B 8 o 27 of phosphors. Na 3 La 8.55 Tb 0.45 B 8 o 27 Phosphor emits bright green light under the excitation of 264nm and 365nm ultraviolet light, Na 3 La 8.55 Eu 0.45 B 8 o 27 The phosphor emits bright red light under the excitation of 264nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com