Method and device for extracting high-purity rhenium from tungsten-rhenium alloy

A tungsten-rhenium alloy, high-purity technology, applied in the field of recovery and extraction of sparse and scattered metal rhenium, can solve the problems of lack of treasure and utilization, and achieve the effects of complete exhaust gas collection, full alloy oxidation, and high separation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

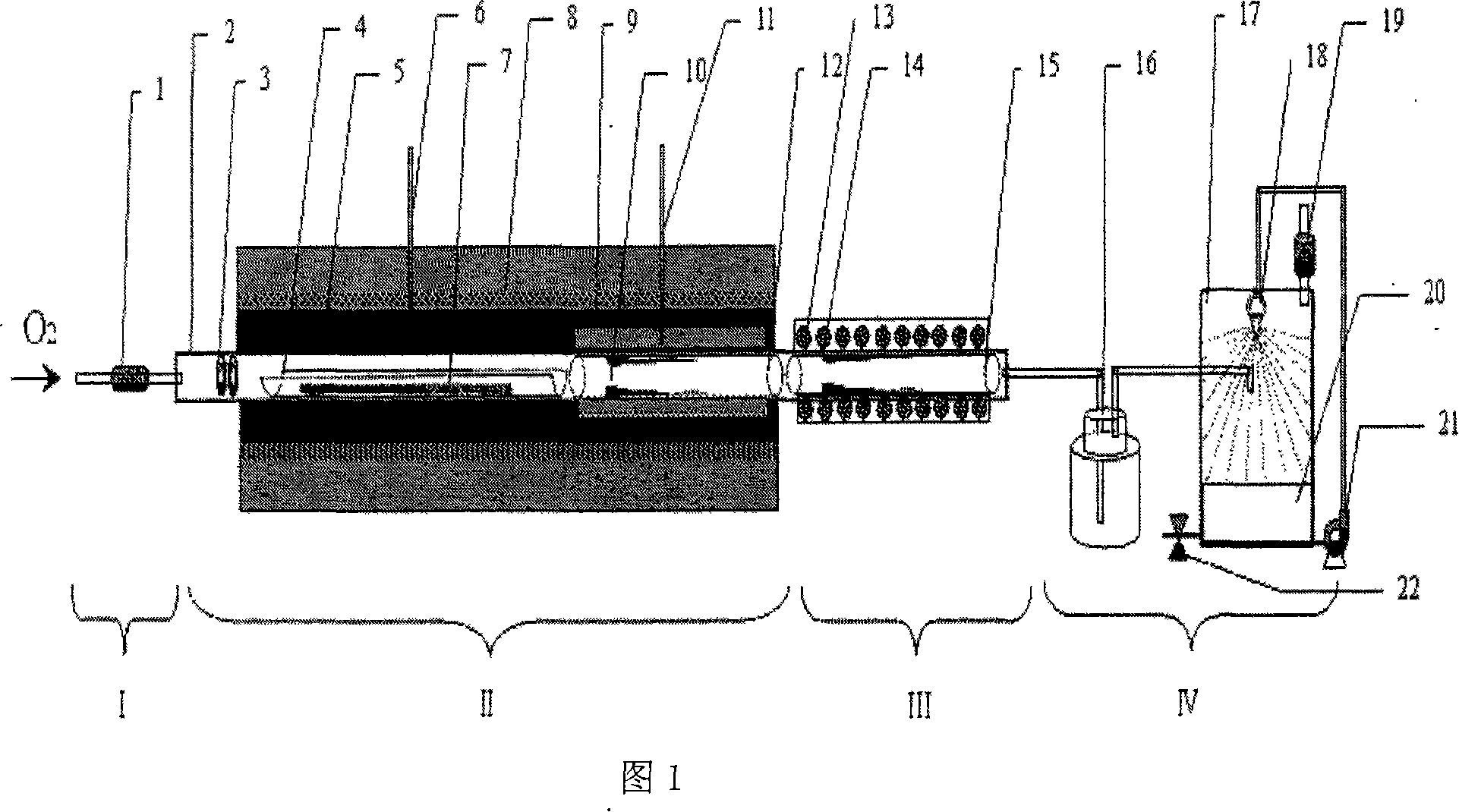

[0020] 1) Cut a total of 100 grams of tungsten-rhenium waste materials containing about 15% rhenium into small pieces and place them on the quartz boat 4, put the quartz boat 4 containing the materials into the high-temperature zone in the quartz furnace tube 2, place the heat shielding bracket 3 into the mouth of the pipe; the material collection pipe 12 in the low temperature zone is put into the low temperature zone of the quartz furnace tube 2, and the material collection pipe 15 in the cooling zone is put into the cooling collection zone III;

[0021] 2) The mouth of the quartz furnace tube 2 high temperature area is connected to oxygen and connected to the digital gas flow meter A1 in series, and the mouth of the quartz furnace tube 2 cooling area is connected to the tail gas buffer and collection device IV; when the system is running, the inlet oxygen and tail gas buffer and collection are first turned on Device IV; then turn on the circulating cooling water of the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com