Distributed leaf type pivoting flexible hinge

A flexible hinge and blade-shaped technology, applied in the direction of shafts and bearings, mechanical equipment, pivots, etc., can solve the problems that are difficult to adapt to large rotation angles, difficult to improve rotation accuracy, and drift of the rotation center, so as to improve the rotation range and fatigue Longevity, good stiffness, effect of improving axial stiffness and radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

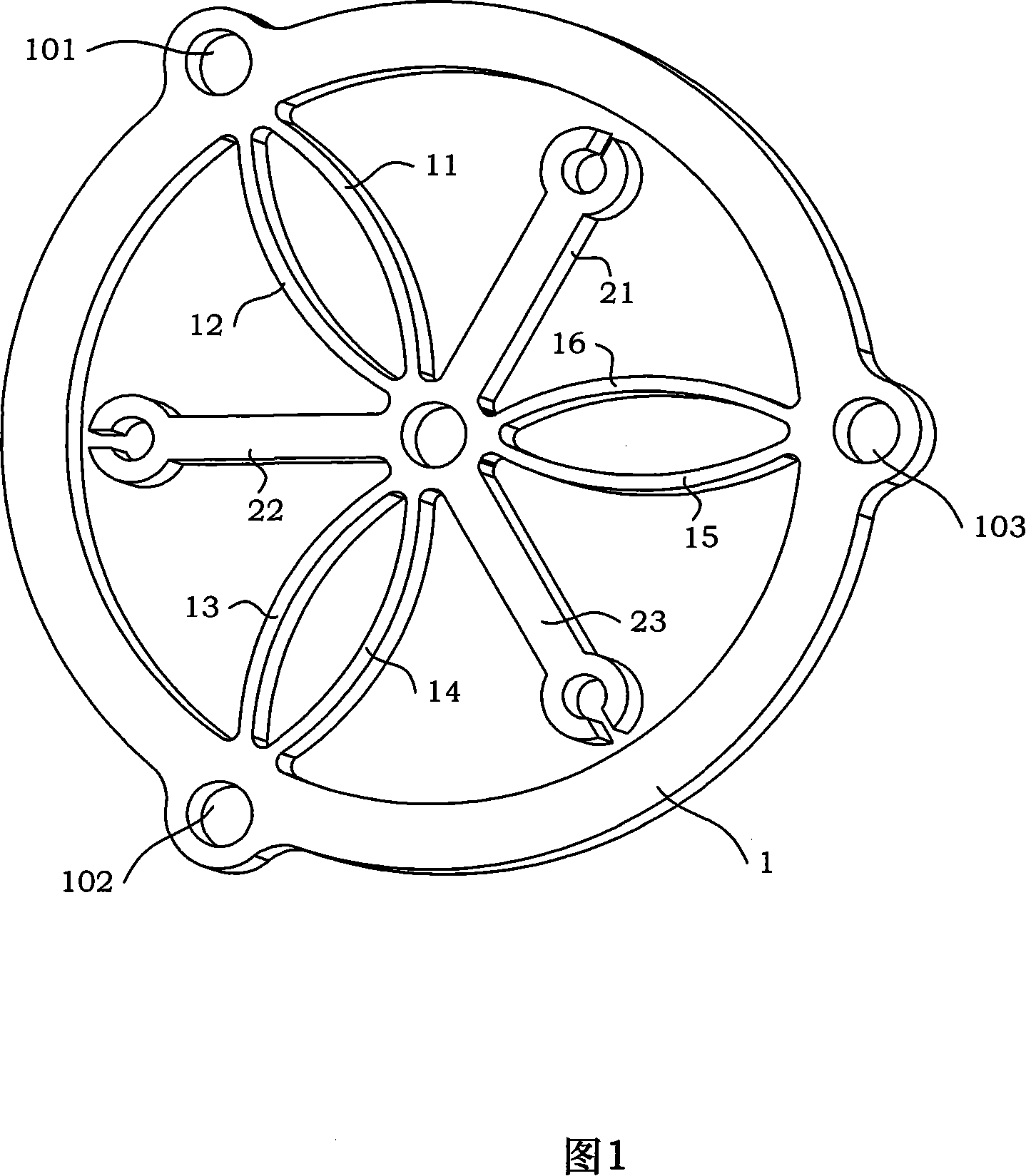

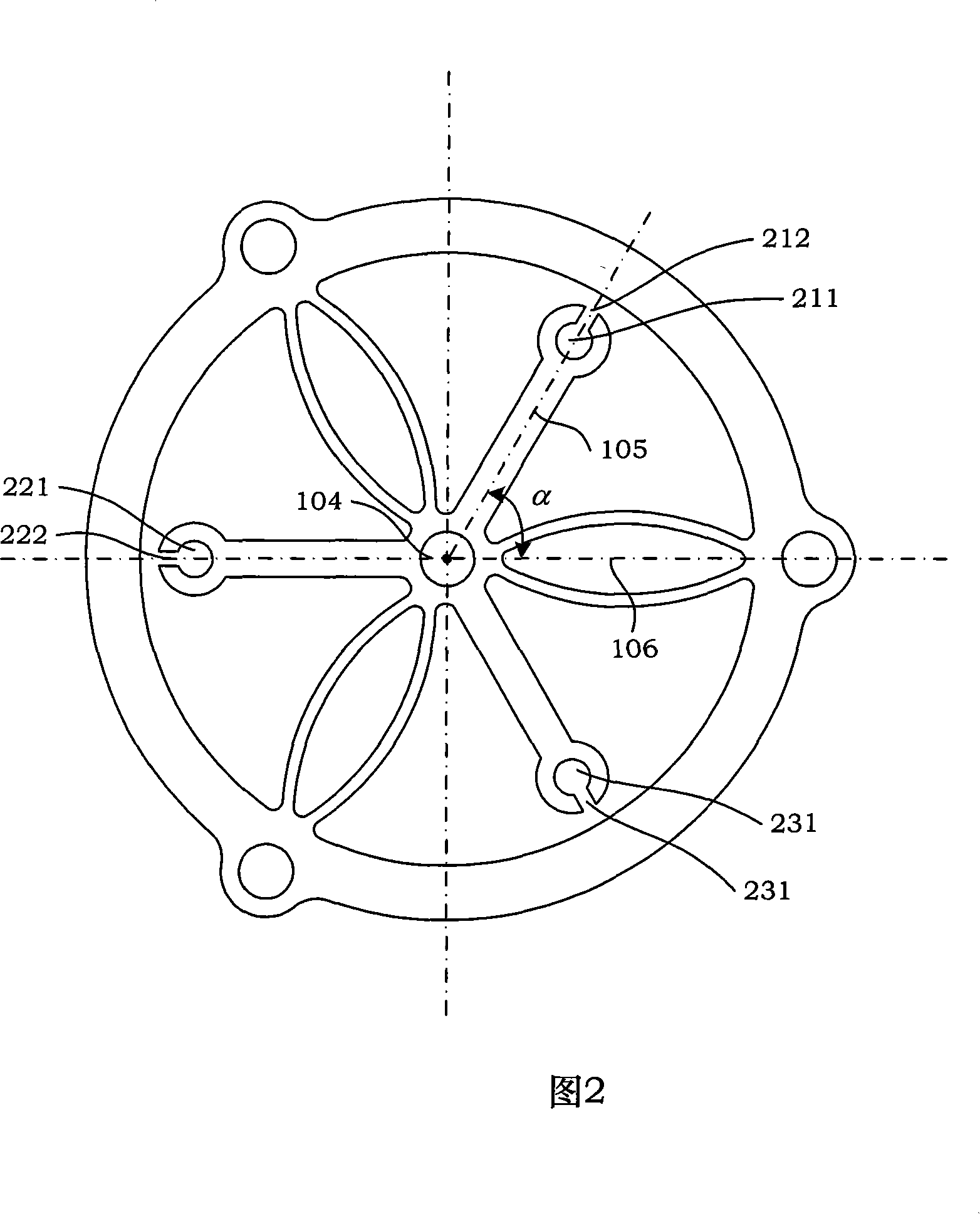

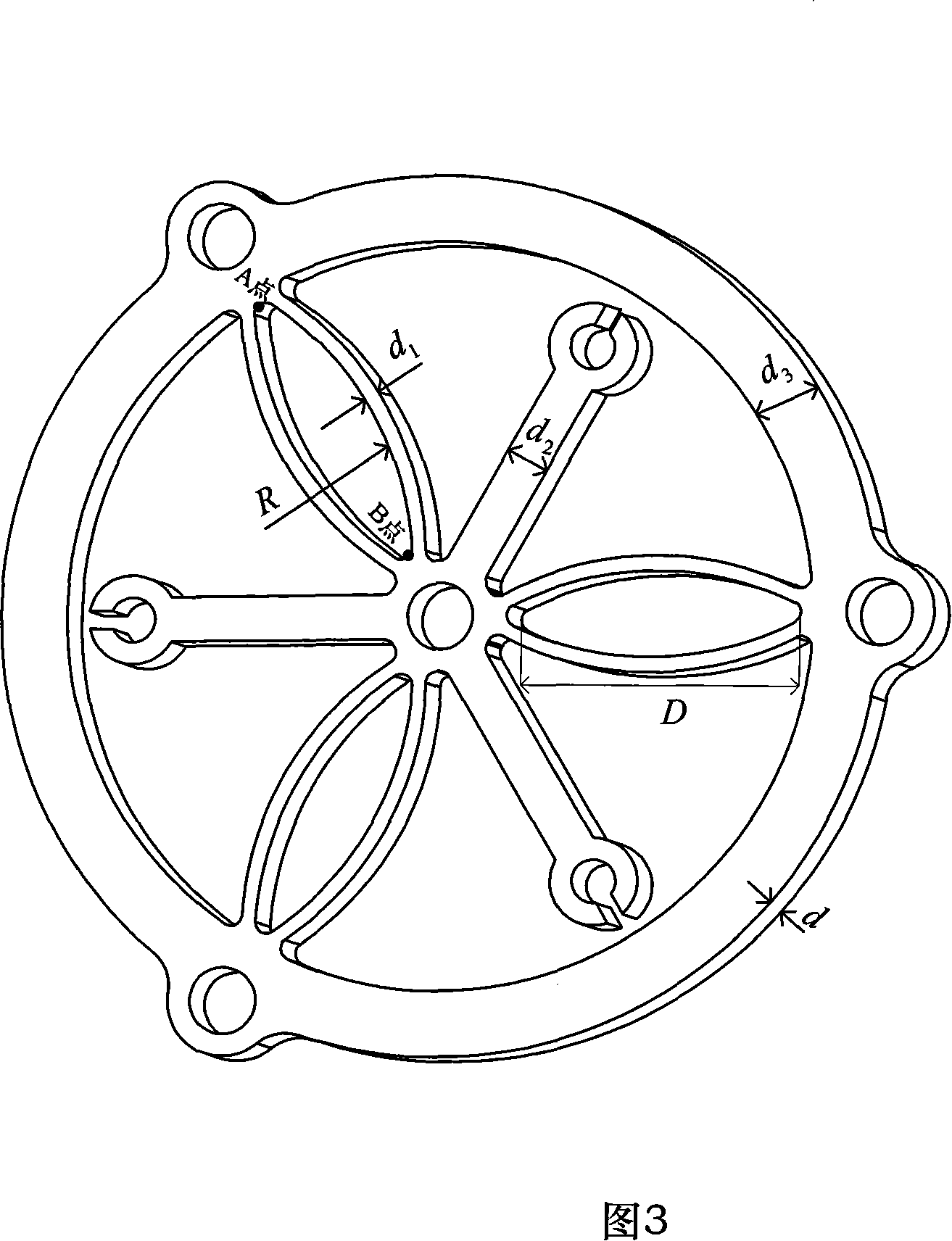

[0020] The present invention is a distributed blade-shaped rotating flexible hinge, which is centered on the axis of the cylinder on the cylinder, and is integrated with a through hole 104, a first reed 11 and a second reed by using a precision wire cutting machine tool. 12. The third reed 13, the fourth reed 14, the fifth reed 15, the sixth reed 16, the first inner arm 21, the second inner arm 22, the third inner arm 23, and the outer ring 1 There are A mounting hole 101, B mounting hole 102, and C mounting hole 103; the first reed 11 and the second reed 12 constitute the first pair of leaf reeds; the third reed 13 and the fourth reed 14 constitute the second Pair of leaf-shaped reeds; the fifth reed 15 and the sixth reed 16 form a third pair of leaf-shaped reeds. Between the first inner arm 21 and the second inner arm 22 is a first pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com