Metalliferous carbon coating composition similar with diamond

A diamond and carbon coating technology, applied in the direction of metal material coating process, coating, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

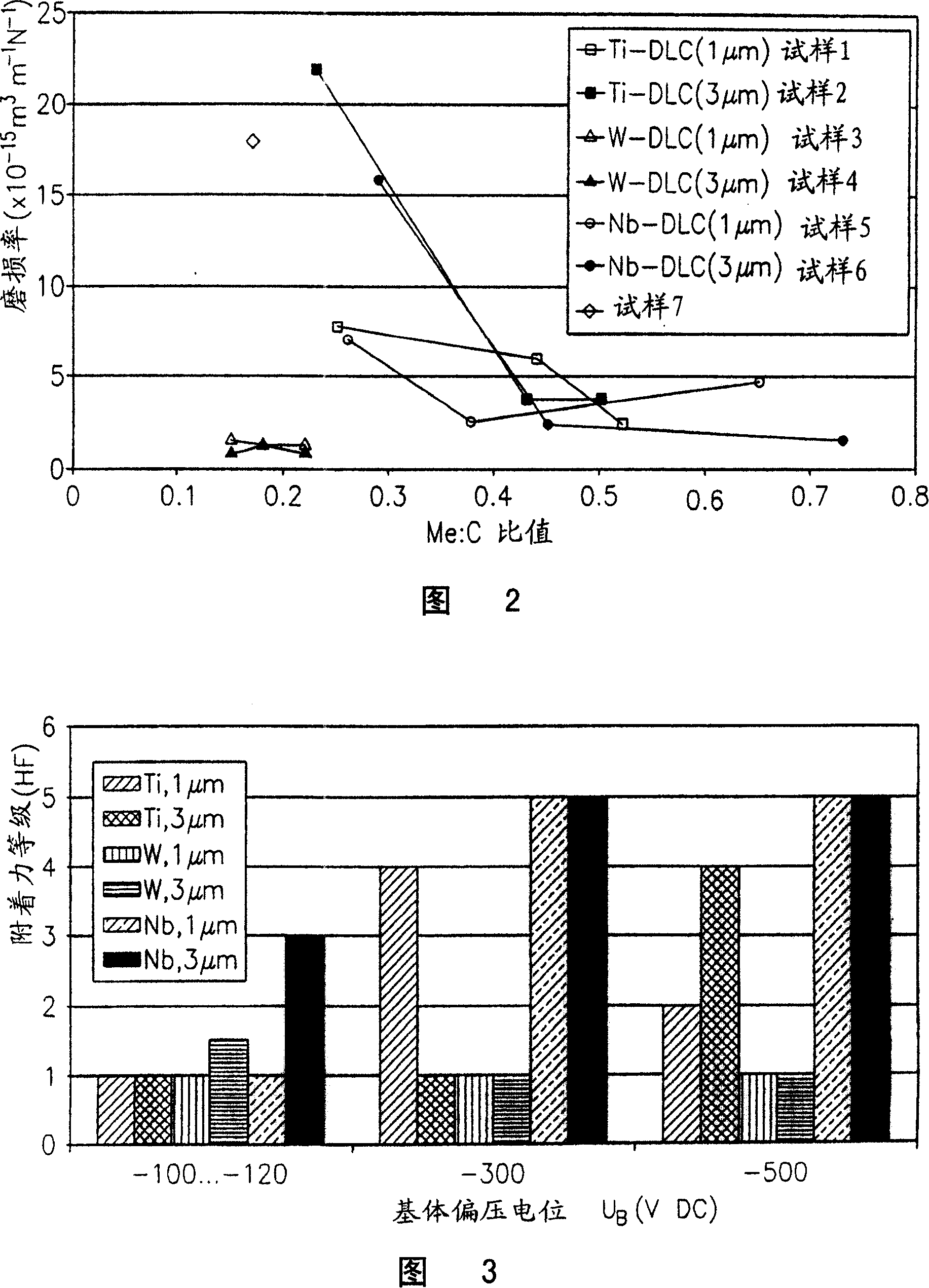

[0022] Metal-diamond-like carbon coatings were deposited by magnetron sputtering, in which four targets including metals of interest were installed inside the deposition chamber, activated and treated with argon (Ar) and acetylene (C 2 h 2 ) gas for sputtering. A deposition substrate comprising a rolling contact fatigue rod, or a substrate 10 comprising a hardened iron-based alloy such as AISI M50, is placed within the deposition chamber and negatively biased with a direct current (DC) potential in the range of about -50 to -750 DC volts . The sputter target composition includes the elements titanium (Ti), niobium (Nb) and tungsten (W).

[0023] Metal hydrocarbons (Me- DLC) coating. Before starting the deposition process, the residual pressure in the vacuum chamber was set to be less than about 10 -3 Pascal (Pa). During the deposition process, the total gas pressure in the vacuum chamber is between about 0.3Pa and 0.6Pa. The substrates referred to herein are supported w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com