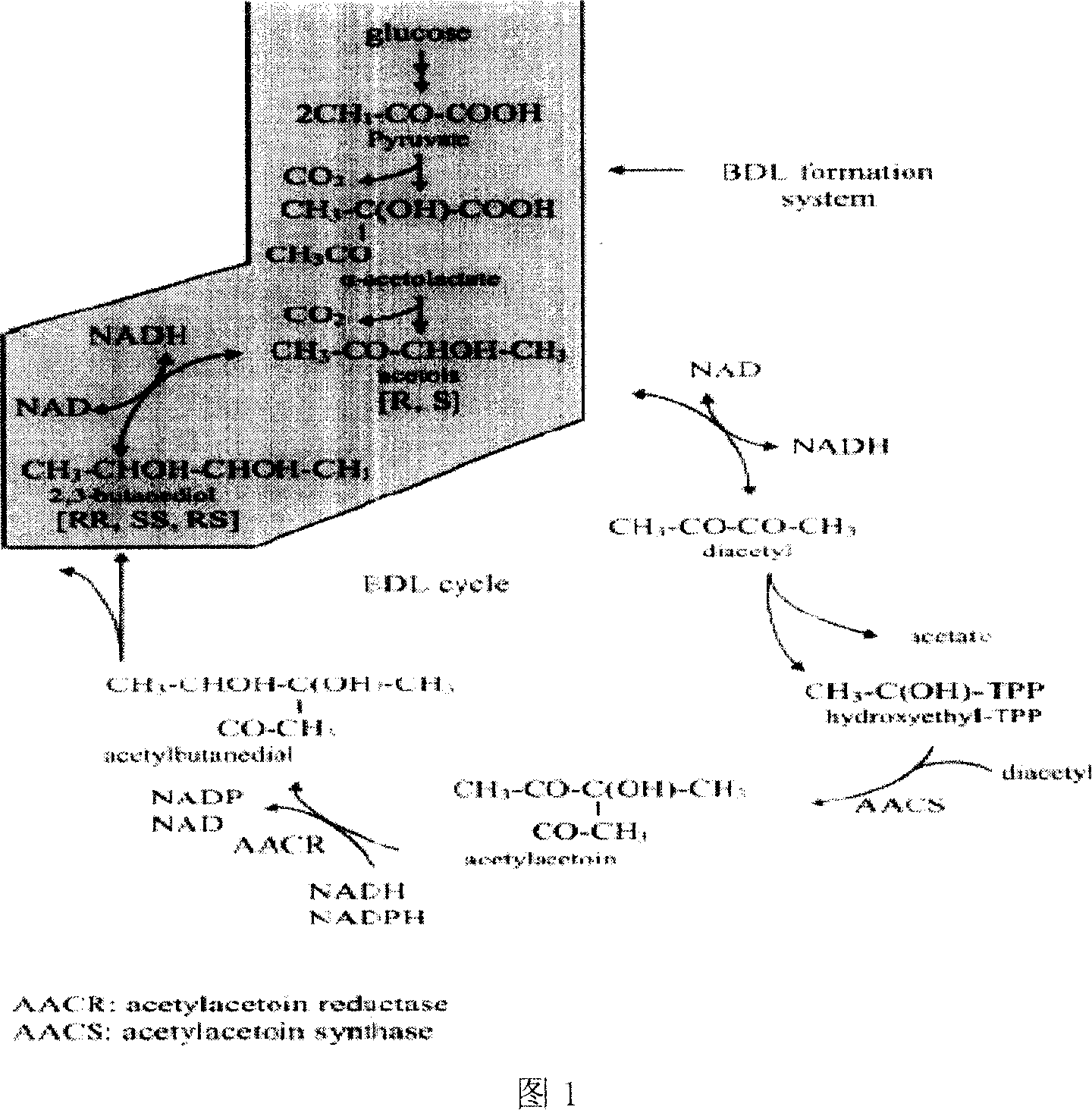

Method for ferment production of 2.3-butanediol by directly enzymolysis of plants stalk

A technology of plant straw and butanediol, which is applied in the field of microbial fermentation, can solve the problems of low concentration of 2.3-butanediol, difficult industrialization of butanediol, difficult distillation and extraction, etc., and achieves high-value utilization, abundant raw materials, and improved The effect of product content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] From the preservation slant of the bacillus strains that can secrete cellulase and produce 2.3-butanediol ability obtained by screening, pick a ring and inoculate it on the 25ml seed medium (the volume of the triangular flask is 100ml), 30-37 ℃, 160 After cultivating for 12-24h under the shaking condition of -220rpm, transfer 7-12% of the inoculum amount into the 50ml liquid fermentation medium (the volume of the Erlenmeyer flask is 250ml) of shaking fermentation culture in which the stalk after the alkali treatment is the only carbon source. For: 30-37°C, 160-220rpm culture for 96-144h; sampling every 24h to measure cellulase filter paper enzyme activity and 2.3-butanediol content; the maximum filter paper enzyme activity of cellulase can reach 0.18-0.26IU / ml ; 2.3-Butanediol output is 0.14-0.24g / L;

[0049] After the fermentation and cultivation are completed, firstly carry out 100-120 mesh filtration to remove the residue in the fermentation broth, and after the filt...

Embodiment 2

[0053] Pick a ring from the slant of the strain test tube and inoculate it in a 25ml seed medium upper triangular flask (the volume of the triangular flask is 100ml), shake (160-220rpm, 30-37°C) for 12-24h, and inoculate according to the inoculum size of 10-13 %Transfer to alkali-treated straw as the only carbon source in the solid-state fermentation medium for shaking culture in the triangular flask (the volume of the triangular flask is 250ml), the amount of sample loaded on the solid-state fermentation medium: 10g of alkali-treated wheat straw+40ml of inorganic salt solution, culture conditions : 30-37°C, 180-220rpm shake flask (volume 250ml) cultured for 120-144h, sampling every 24h to measure cellulase filter paper enzyme activity and 2.3-butanediol content; cellulase filter paper enzyme activity can reach 2.1- 4.7IU / g dry material, the output of 2.3-butanediol can be 0.026-0.067g / g dry material; after the solid-state fermentation is completed, use n-butanol, n-butanol ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com