Method for preparing complex nanometer fibrous tissue renovation bracket containing collagen

A technology of composite nanofibers and collagen, which is applied in the field of preparation of composite nanofiber tissue repair scaffolds, can solve the problems that have not been reported, cannot meet the requirements of mechanical properties of tissue repair materials, and the mechanical properties of materials are low, and achieve good biological Compatibility, excellent mechanical properties, effects of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

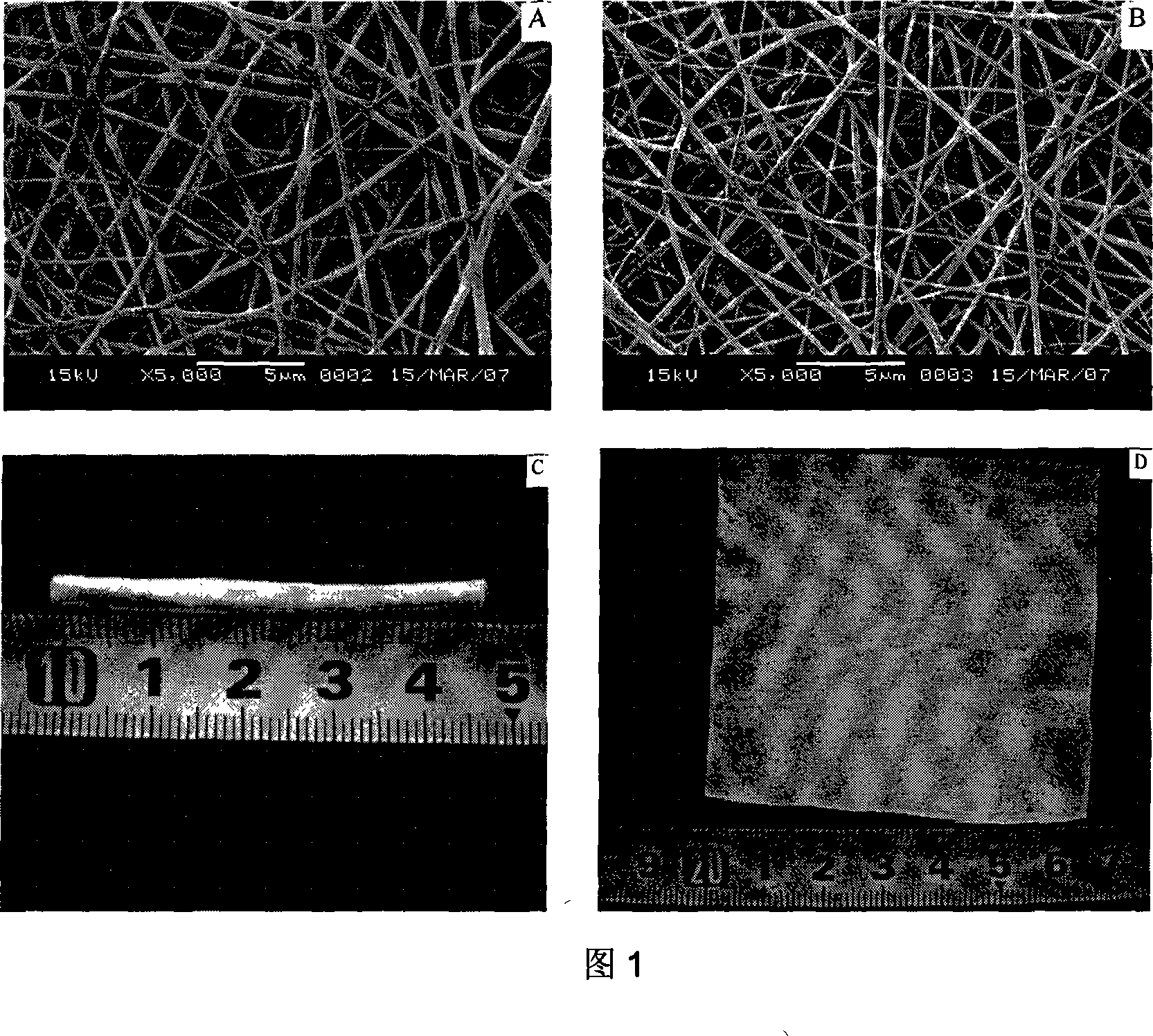

Embodiment 1

[0021] Take by weighing 0.3g collagen protein and dissolve in 5ml hexafluoroisopropanol with an electronic analytical balance, stir until completely dissolving by microthermal magnetic force, obtain the collagen protein spinning solution that concentration is 6% (g / ml); weigh with electronic analytical balance Get 0.3g of thermoplastic polyurethane and dissolve in 5ml of hexafluoroisopropanol, slightly heat and magnetically stir until completely dissolved to obtain a thermoplastic polyurethane spinning solution with a concentration of 6% (g / ml); The ratio of 2:8 is mixed evenly, and the total concentration of the mixed solution is 6%. The electrospinning spinning process is as follows: the spinning voltage is 12kv, the advancing speed of the syringe pump is 1.5ml / h, the receiving distance is 12cm, the needle of No. 9 is selected, and the aluminum foil accepts Or degreasing gauze accepts the fiber to obtain a disordered nanofiber film with an average fiber diameter of about 345 ...

Embodiment 2

[0023] Take by weighing 0.3g collagen protein and dissolve in 5ml hexafluoroisopropanol with an electronic analytical balance, stir until completely dissolving by microthermal magnetic force, obtain the collagen protein spinning solution that concentration is 6% (g / ml); weigh with electronic analytical balance Get 0.3g of thermoplastic polyurethane and dissolve in 5ml of hexafluoroisopropanol, slightly heat and magnetically stir until completely dissolved to obtain a thermoplastic polyurethane spinning solution with a concentration of 6% (g / ml); The ratio of 6:4 is mixed evenly, and the total concentration of the mixed solution is 6%. The electrospinning spinning process is as follows: the spinning voltage is 16kv, the advancing speed of the syringe pump is 1.2ml / h, the receiving distance is 12cm, the No. 9 needle is selected, and the aluminum foil accepts Or degreased gauze accepts the fibers to obtain a disordered nanofiber film with an average fiber diameter of about 208 nan...

Embodiment 3

[0025] Take by weighing 0.4g collagen protein and be dissolved in 5ml hexafluoroisopropanol with electronic analytical balance, microheating magnetic force stirs until dissolving completely, obtain the collagen protein spinning solution that concentration is 8% (g / ml); Weigh with electronic analytical balance Get 0.5g thermoplastic polyurethane and be dissolved in 10ml hexafluoroisopropanol, slightly heat magnetically stir until completely dissolving, obtain the thermoplastic polyurethane spinning solution that concentration is 5% (g / ml); The ratio is 5:8 and mixed evenly, the total concentration of the mixed solution is 6.2%; the electrospinning spinning process is as follows: the spinning voltage is 16kv, the advancing speed of the syringe pump is 1.2ml / h, the receiving distance is 12cm, and the No. 9 needle is selected. Aluminum foil accepts or degreased gauze accepts fibers to obtain a disordered nanofiber film with a thickness of 0.08 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com