Fluorin-containing acrylic resin having ultra-low surface energy and preparation method and application in paint thereof

A technology of acrylic resin and acrylic acid, applied in the field of fluorine-containing acrylic resin and its preparation, to achieve the effects of improving storage stability, prolonging aging and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In order to solve the second technical problem above, the present invention provides a method for preparing a fluorine-containing acrylic resin with ultra-low surface energy, the steps of which are as follows: adding the monomer and initiator in the above formula into a solvent to undergo free radical polymerization, A fluorinated acrylic resin solution is generated; then a modifier is added to the resin solution for graft polymerization.

[0038] A further improved technical solution, a method for preparing a fluorine-containing acrylic resin with ultra-low surface energy, the steps are as follows: add the solvent into the reactor, start stirring and heat to 75-85°C or 95-105°C , filled with nitrogen protection at the same time; acrylate or methacrylate hard monomer, acrylate or methacrylate soft monomer, hydroxy acrylate or methacrylate hydroxy ester, fluorine-containing acrylate monomer, acrylic or methyl Acrylic acid is mixed with the initiator accounting for 75-85%...

Embodiment 1

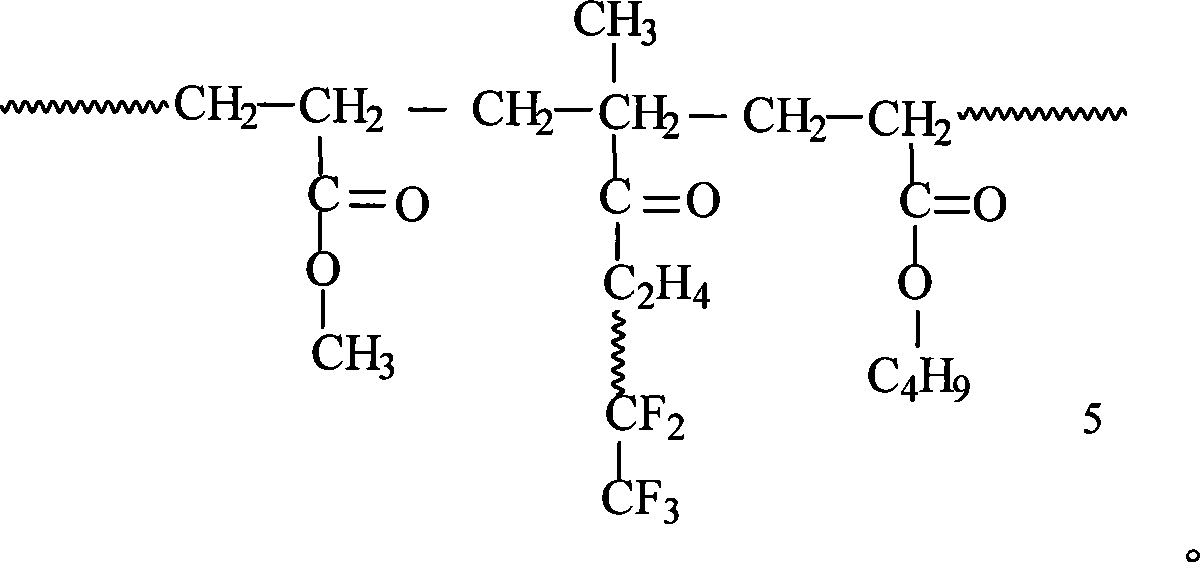

[0040] A kind of fluorine-containing acrylic resin with ultra-low surface energy of the present invention, its structural formula is shown as follows:

[0041]

[0042] The fluorine-containing acrylic resin with ultra-low surface energy of the above structural formula is made of the following raw materials in weight percentage:

[0043] Methyl acrylate 20%;

[0044] Butyl Acrylate 15%;

[0045] β-Hydroxypropyl Acrylate 5%;

[0046] 3-fluoroethyl methacrylate 8.5%;

[0047] Acrylic acid 0.5%;

[0048] Modifier 0.5%;

[0049] Xylene 25%;

[0050] Butyl acetate 25%;

[0051] Azobisisobutyronitrile 0.5%.

[0052] The modifier is a perfluoroalkyl compound containing active end groups, and this perfluoroalkyl compound has the following structure:

[0053]

[0054] The modifier is n=6 in the formula.

[0055] A preparation method of a fluorine-containing acrylic resin with ultra-low surface energy of the present invention, the steps are as follows: add xylene and butyl a...

Embodiment 2

[0059] A kind of fluorine-containing acrylic resin with ultra-low surface energy of the present invention is made of the raw materials of following weight percent:

[0060] Methyl methacrylate 22%;

[0061] Ethyl Acrylate 14%;

[0062] β-Hydroxyethyl Acrylate 10%;

[0063] 4-Fluorodecyl Methacrylate 10.5%;

[0064] Methacrylic acid 1%;

[0065] Modifier 1%;

[0066] MEK 40%:

[0067] Benzoyl Peroxide 1.5%.

[0068] The modifier is a perfluoroalkyl compound containing active end groups, and this perfluoroalkyl compound has the following structure:

[0069]

[0070] The modifier is n=8 in the formula.

[0071] A kind of preparation method of the fluorine-containing acrylic resin with ultra-low surface energy of the present invention, its steps are as follows:

[0072] Add methyl ethyl ketone into the reactor, start stirring and heat to 105°C, and fill with nitrogen protection at the same time; methyl methacrylate, ethyl acrylate, β-hydroxyethyl acrylate, 4-fluorodecyl...

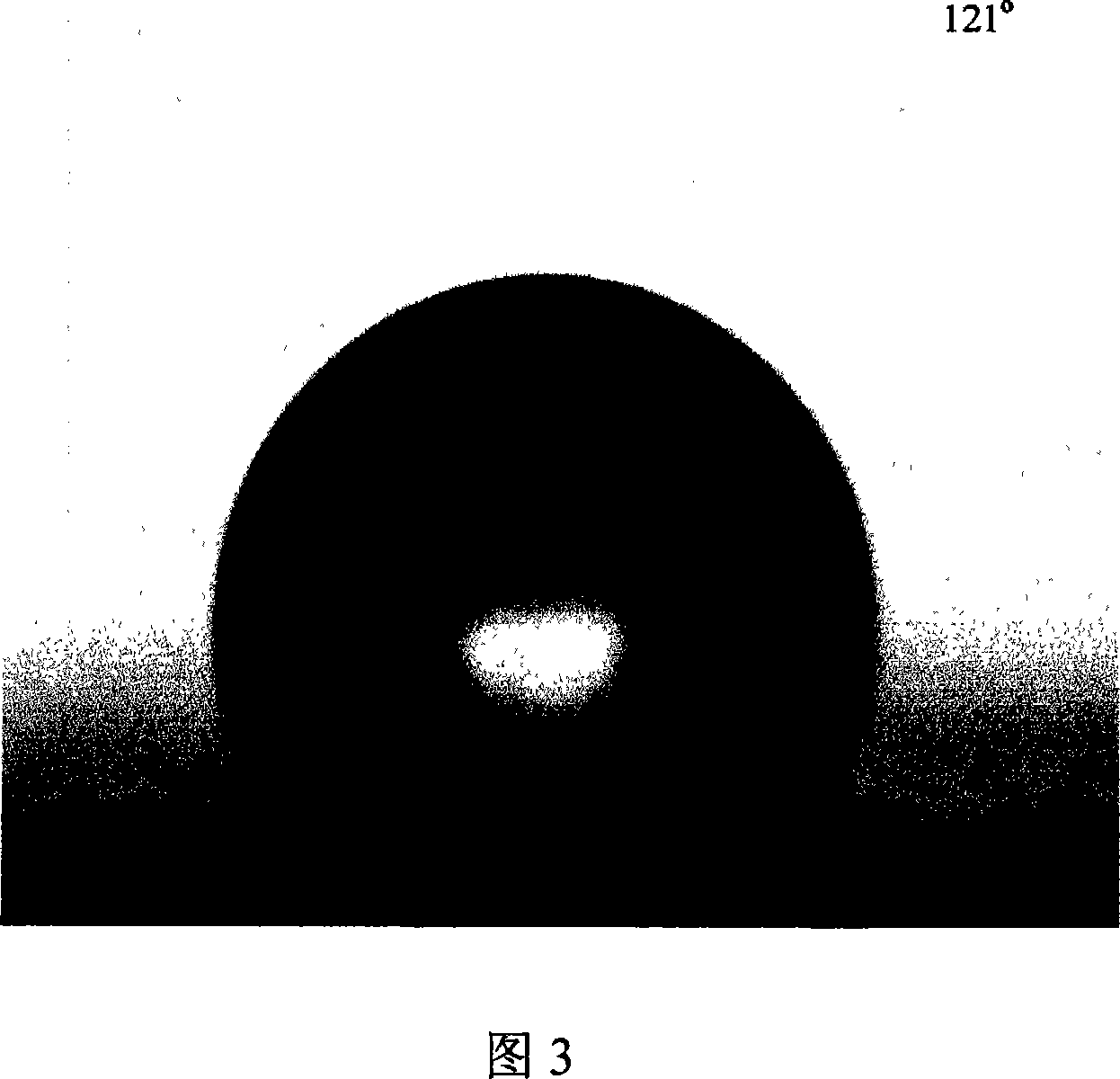

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com