Aligning mark, alignment method and aligning system

A technology for aligning systems and aligning marks, which is applied in the fields of optics, instruments, and photoplate-making processes on patterned surfaces, and can solve problems such as low power, complexity, and inability to use high-order signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

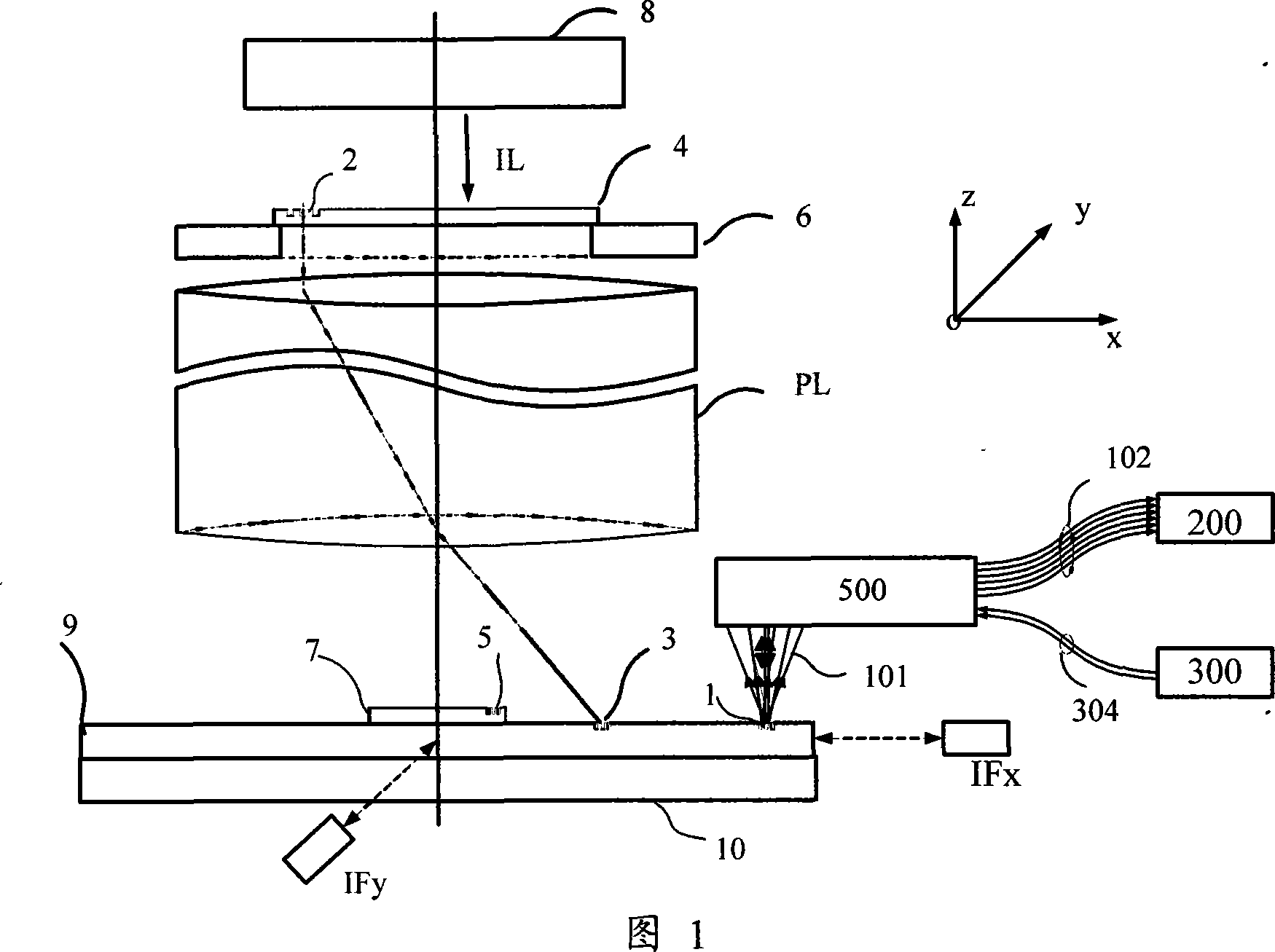

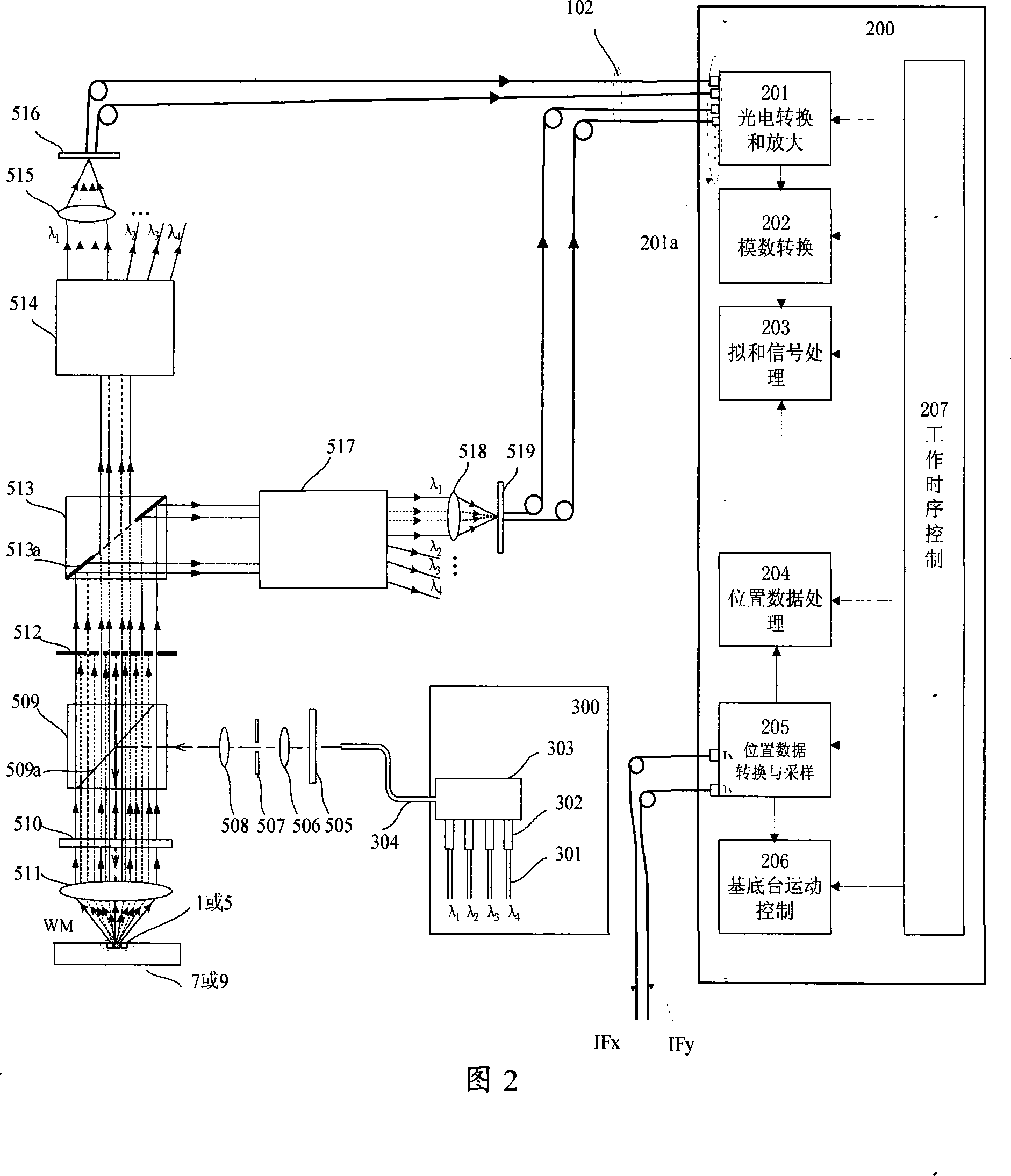

[0053] Figure 1 shows a schematic diagram of a prior art alignment system used by a photolithography machine. The composition of the lithography apparatus includes: an illumination system 8 for providing an exposure beam; a mask table 6 for supporting a reticle 4, on which there is a mask pattern and an alignment mark 2 with a periodic structure; A projection optical system PL that projects the mask pattern on the reticle 4 onto the wafer 7; a substrate table 9 for supporting the wafer 7, and an alignment mark 3 is engraved on the substrate table 9; it is used for the substrate table and the wafer 7 An off-axis alignment optical system 500 for circular alignment and an alignment radiation source 300 for providing alignment illumination; a signal processing unit 200 for alignment signal acquisition, processing, and fitting; a drive system for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com