Plastic shielding cover board

A shielding cover and plastic technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of the large number of metal spacer assembled cover plates, the difficult processing of metal die-casting cover plates, and the difficulty of installation and operation. Electromagnetic shielding effectiveness, simple structure, and weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

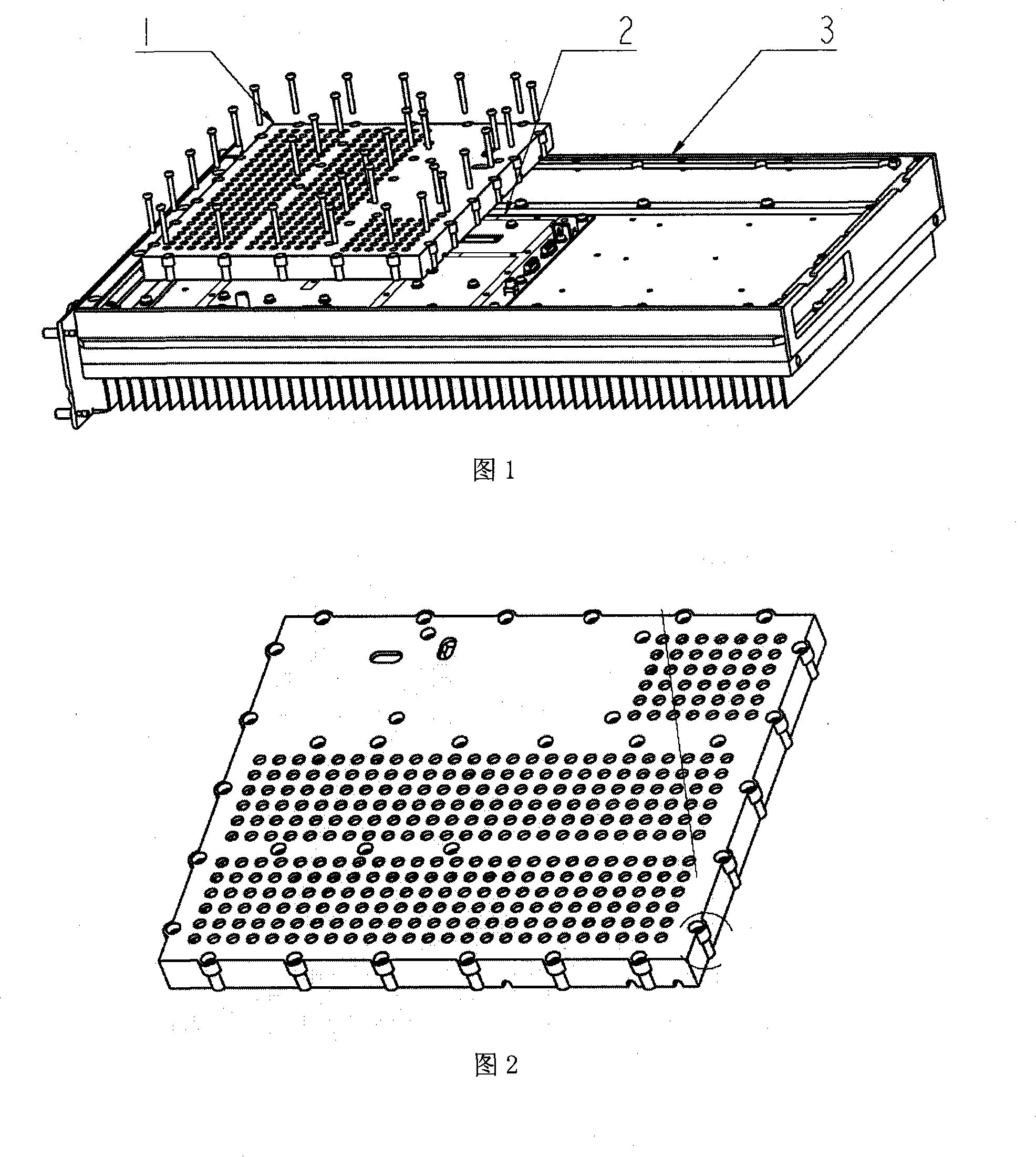

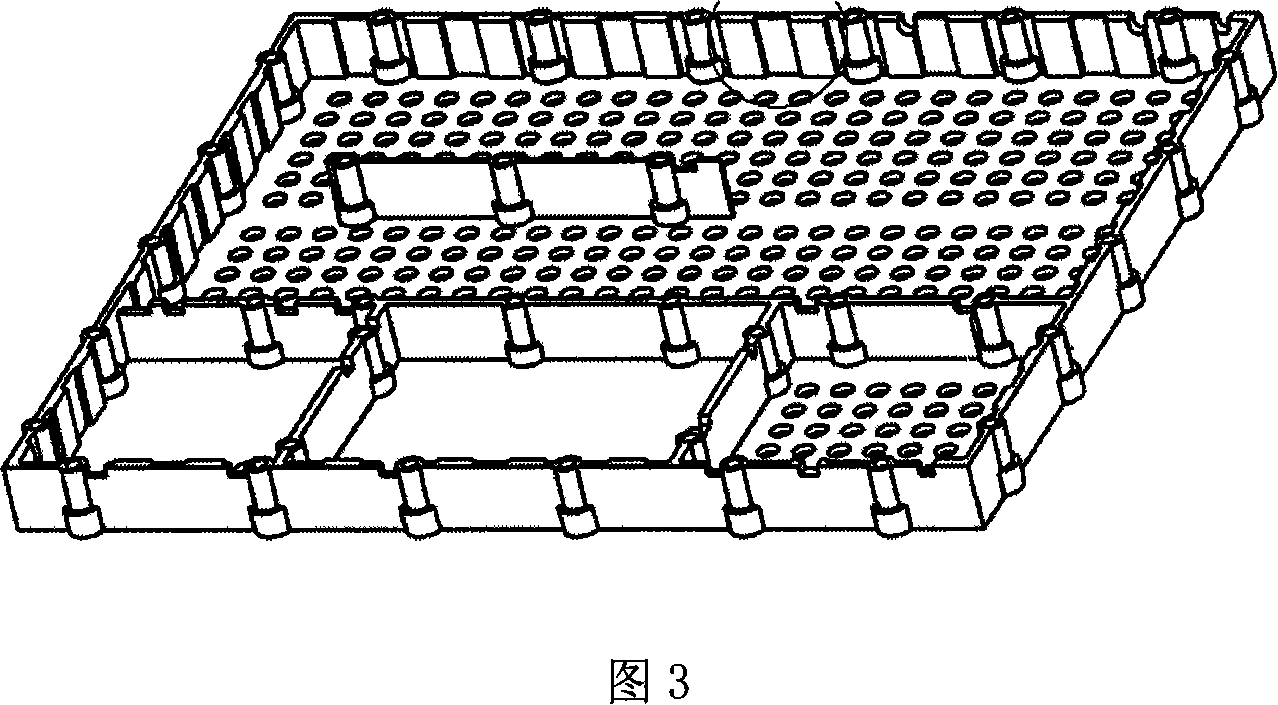

[0021] The conductive plastic shielding cover plate proposed by the present invention is shown in accompanying drawings 2 and 3, and the installation of the conductive plastic cover plate is shown in accompanying drawing 1. Its main features and functions are as follows:

[0022] The conductive plastic cover plate is used in the radio frequency, difference frequency and amplifying circuit of the radio frequency power amplifier, which plays a dual role of protection and electromagnetic shielding. The conductive plastic shielding cover plate has the following characteristics: the material of the cover plate is made of conductive plastic, and conductive fibers and particles are added to the plastic base material. The plastic base material is polycarbonate PC, engineering plastic ABS, polypropylene PP, etc. Molecular materials, conductive fibers and particles are stainless steel fibers, aluminum alloy fibers, nickel-plated carbon fibers, nickel powder, carbon powder, graphite, etc....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com