Preparation technique of 2-amido-3,6,8-naphthalenetrisulphonic acid

A technology for the preparation of naphthalene trisulfonic acid, which is applied in the fields of sulfonic acid preparation and organic chemistry, and can solve problems such as environmental hazards, high cost, and difficult wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

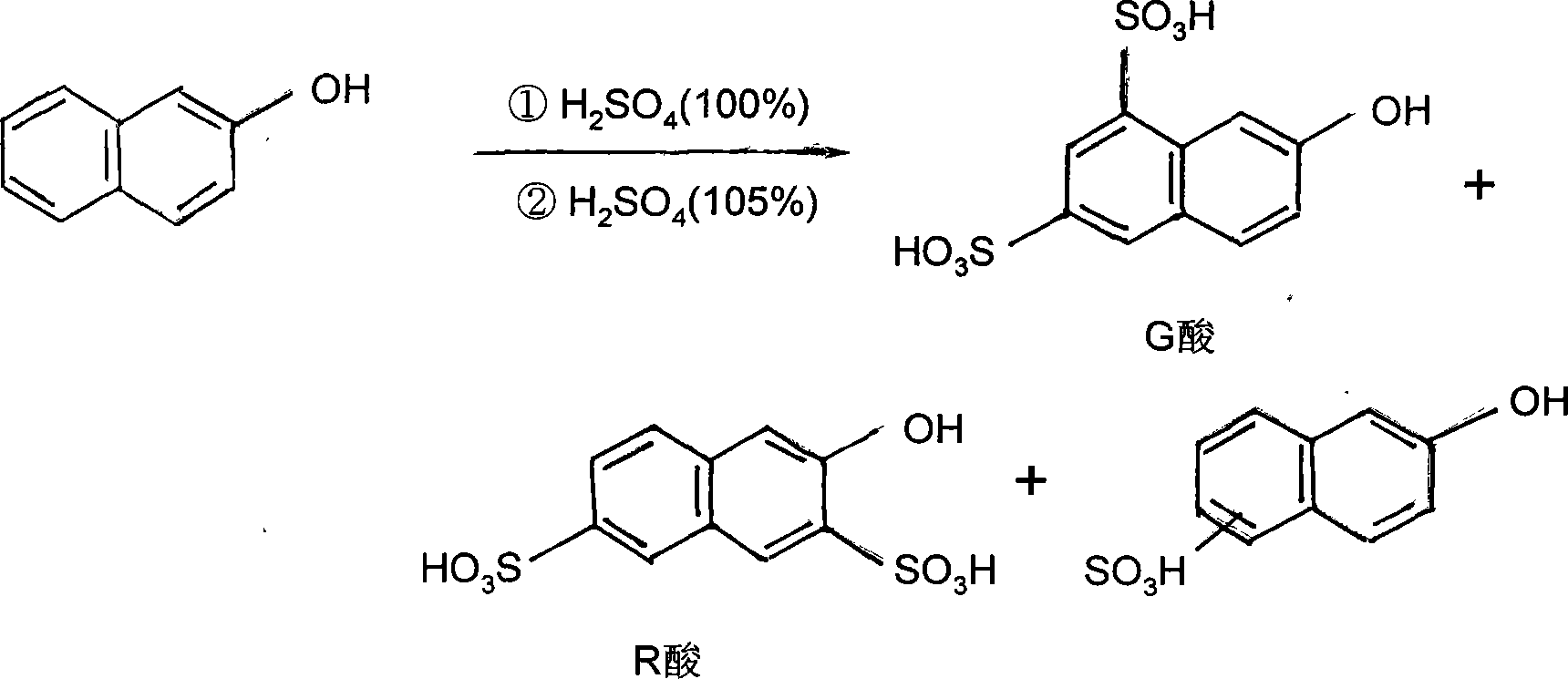

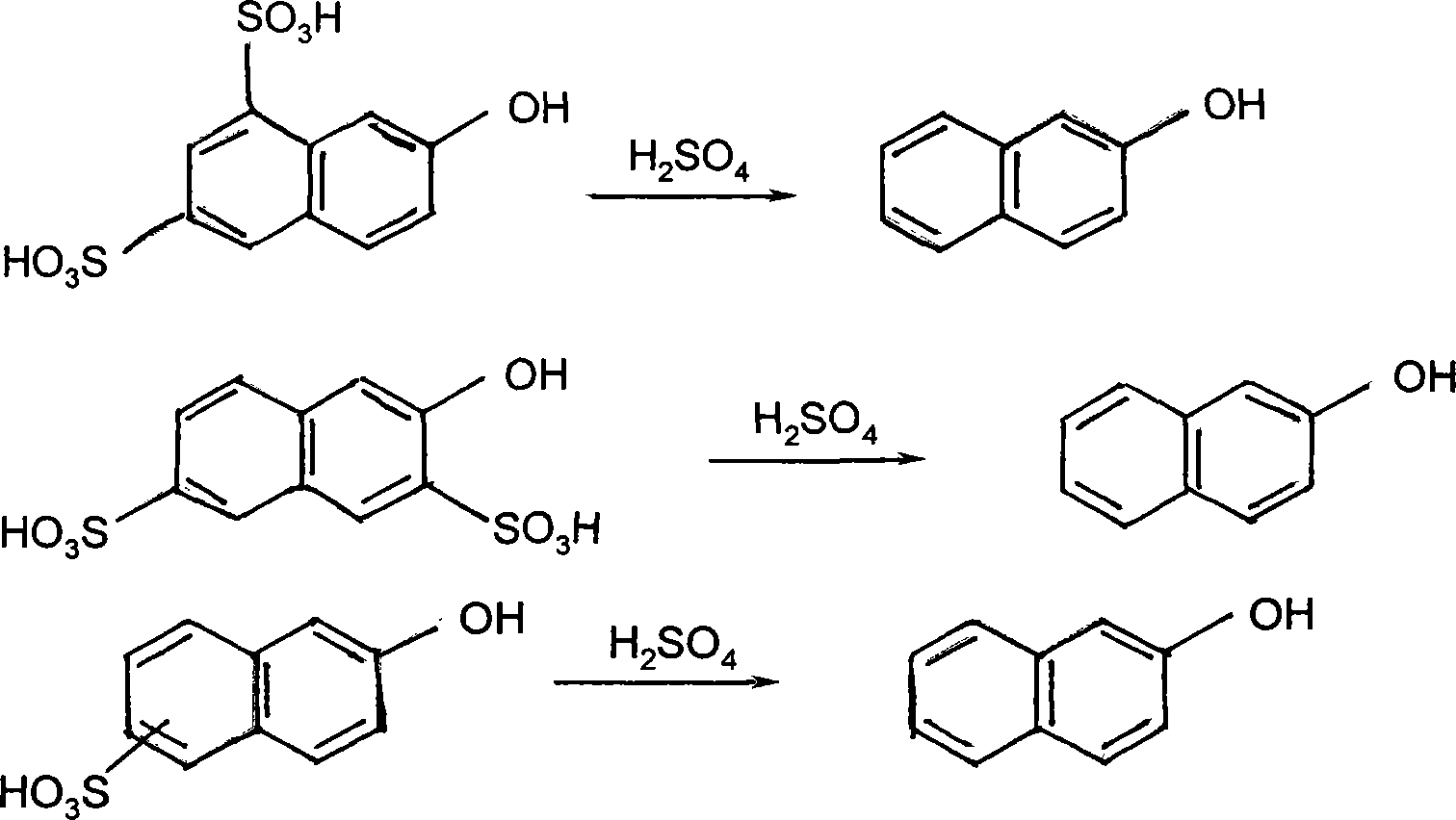

Method used

Image

Examples

Embodiment 1

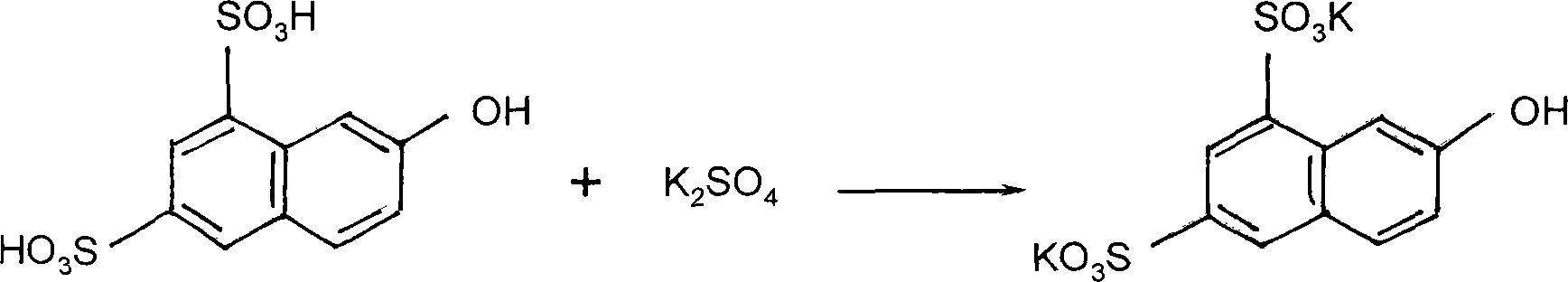

[0018] In the four-necked flask equipped with stirring, add 88g of 98% sulfuric acid, add 100g of 2-naphthol under stirring and cooling, stir for 30 minutes, then add 190g of 105% sulfuric acid, and react for 6 hours after the addition. After the reaction, the The sulfonate was added to a solution of 170 g of potassium sulfate dissolved in 600 ml of water, stirred for 2 hours after the addition, and filtered to obtain 240 g of the product, wherein the content of potassium 6,8-naphthalene disulfonate was 71%.

[0019] The above-mentioned potassium 6,8-naphthalene disulfonate was dissolved in a mixed solution of 260ml of ammonia water and 62ml of ammonium bisulfite, added to an autoclave, heated to 140°C, kept for 12 hours, cooled, the mother liquor was decolorized by activated carbon, acidified, and filtered , oven dry, obtain product 155g, wherein 7-amino-1,3-naphthalenedisulfonic acid (amino G acid) content is 82.6%.

[0020] Sulfonate 155g of the above-mentioned dried produc...

Embodiment 2

[0023] In a 3000L glass-lined reactor, add 88kg of 98% sulfuric acid. Add 1000kg of 2-naphthol under stirring and cooling. After the addition, stir for 30 minutes, then add 1900kg of 105% sulfuric acid, and react at 80-85°C for 6 hours after the addition. After the reaction, the sulfonate was added to a solution of 1700kg of potassium sulfate dissolved in 600kg of water at a temperature not exceeding 90°C, stirred for 2 hours after the addition, and filtered to obtain 6,8-naphthalene disulfonic acid with a content of 72.3%. Potassium 2458kg.

[0024] The above-mentioned potassium 6,8-naphthalene disulfonate was dissolved in a mixed solution of 2650L of ammonia water and 650L of ammonium bisulfite, added into an autoclave, heated to 140°C, and kept for reaction for 12 hours. The temperature was lowered, the mother liquor was decolorized by active carbon, acidified, filtered, and dried to obtain 1612 kg of 7-amino-1,3 naphthalene disulfonic acid with a content of 81.3%.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com