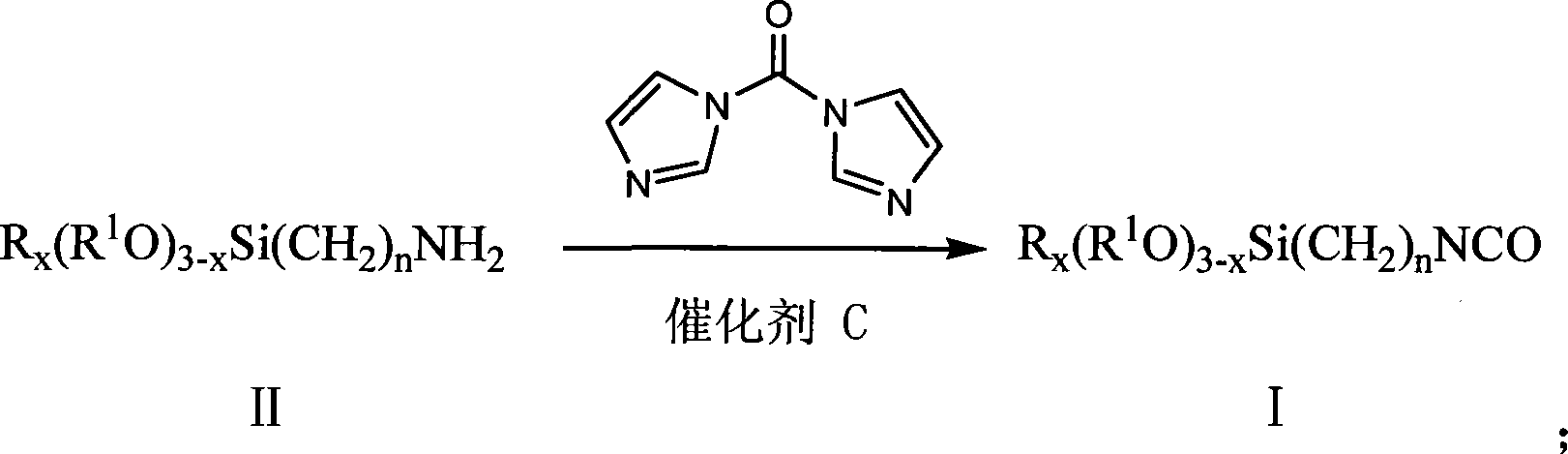

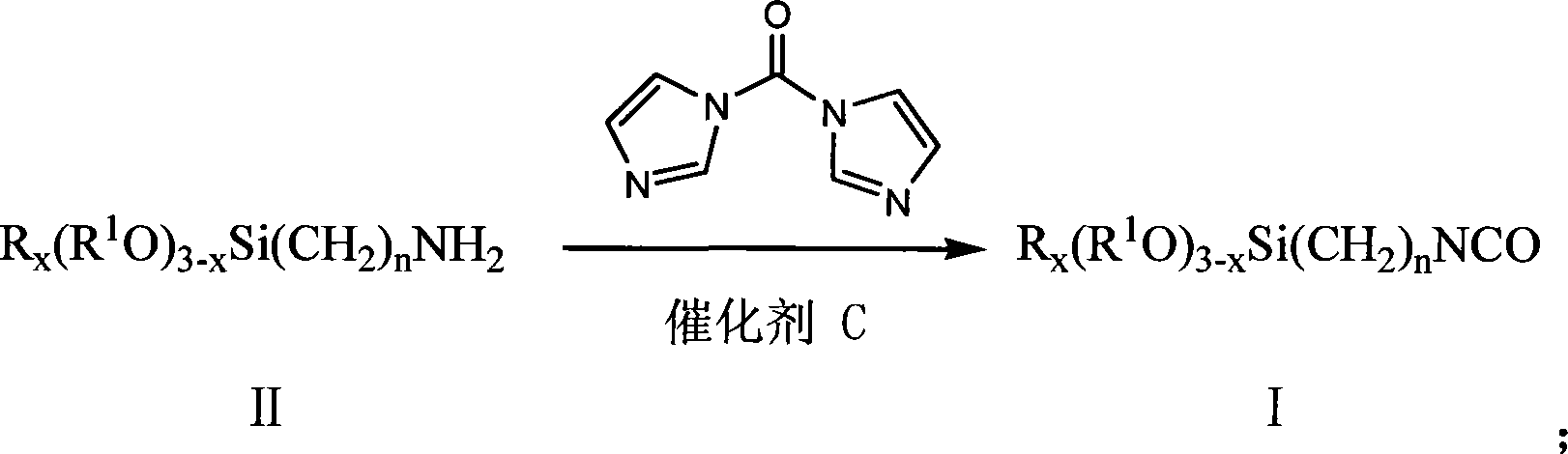

Method for synthesizing isocynate silane coupling agent

A technology of ester silane coupling agent and synthesis method, which is applied in the field of synthesis of isocyanate silane coupling agent, can solve environmental threats and other problems, and achieve the effects of no three wastes, low production cost and reasonable process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In a 1000ml four-necked flask equipped with mechanical stirring, a dry constant pressure dropping funnel, a reflux condenser and a thermometer, add 0.1mol of triethoxyaminopropylsilane and 1% of dicyclohexylcarboimide under nitrogen protection (Dcc) and 350ml tetrahydrofuran, start stirring, and slowly add 0.12mol solution of carbonyldiimidazole dissolved in 100ml tetrahydrofuran dropwise at 0-10°C, react at 0-10°C for 2 hours, heat up to 40°C for 15 hours, The tetrahydrofuran was evaporated, and the obtained crude product triethoxyaminopropyl silane was distilled under reduced pressure, and bp145-152°C / 25mmHg was collected to obtain the crude product isocyanate propyl triethoxy silane, with a yield of 76% and a content of 97.8 %(GC).

Embodiment 2

[0025] In a 1000ml four-necked flask equipped with mechanical stirring, a dry constant pressure dropping funnel, a reflux condenser and a thermometer, add 0.1mol of triethoxyaminopropylsilane and 1% of dicyclohexylcarboimide under nitrogen protection (Dcc) and 350ml tetrahydrofuran, start stirring, slowly add 0.15 mol solution of carbonyldiimidazole dissolved in 100ml tetrahydrofuran dropwise at 0-10°C, react at 0-10°C for 1 hour, then raise the temperature to 30°C for 6 hours, The tetrahydrofuran was distilled off, and the obtained crude product isocyanate propyltriethoxysilane was distilled under reduced pressure, and the bp145-152°C / 25mmHg was collected, with a yield of 78% and a content of 97.1% (GC).

Embodiment 3

[0027] In a 1000ml four-necked flask equipped with mechanical stirring, a dry constant pressure dropping funnel, a reflux condenser and a thermometer, add 0.1mol of triethoxyaminopropylsilane and 1% of dicyclohexylcarboimide under nitrogen protection (Dcc) and 350ml tetrahydrofuran, start stirring, slowly add 0.20mol solution of carbonyldiimidazole dissolved in 100ml tetrahydrofuran dropwise at 0-5°C, react at 0-10°C for 2 hours, heat up to 20°C for 15 hours, Tetrahydrofuran was distilled off, and the obtained crude product, isocyanate propyltriethoxysilane, was distilled under reduced pressure to collect bp145-152°C / 25mmHg, with a yield of 85% and a content of 97.9% (GC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com