Method for extracting and separating shikimic acid from star anise

A technology of star anise and shikimic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of long production cycle, high cost, and low yield, and achieve short production cycle, low cost, and high product yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

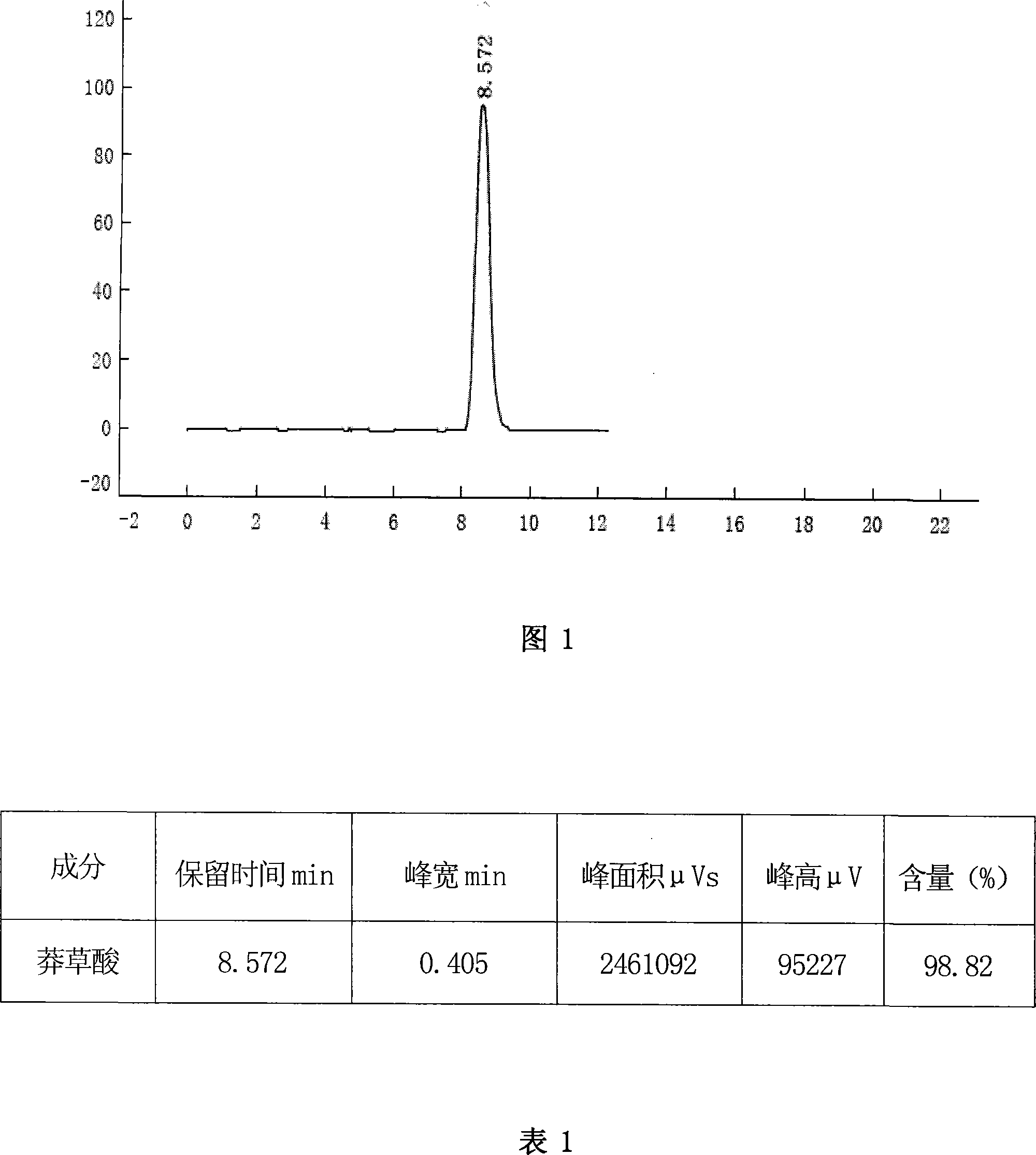

[0042] Embodiment 1: Take 1000 kilograms of pulverized star anise raw materials, and degrease them with petroleum ether with a flat-rotating extractor. The degreased material was extracted 3 times with 80% ethanol with 6 times the volume of heat under reflux, the first two times were 1.5 hours each, and the third time was 1 hour. The extracts were combined, filtered and concentrated to a relative density of 1.15. Add 2 times the amount of water, decolorize with 3% activated carbon at 60°C until the liquid turns pale yellow, concentrate under reduced pressure to a relative density of 1.21, place at room temperature for 48 hours, centrifuge, and filter to obtain crude crystals. The crude crystals were dissolved in 70% ethanol, decolorized with 5% activated carbon until colorless, concentrated to a relative density of 1.20, left to crystallize for 30 hours, centrifuged with a centrifuge, filtered, and dried to obtain 54.0 kg of shikimic acid product. The content of shikimic acid ...

Embodiment 2

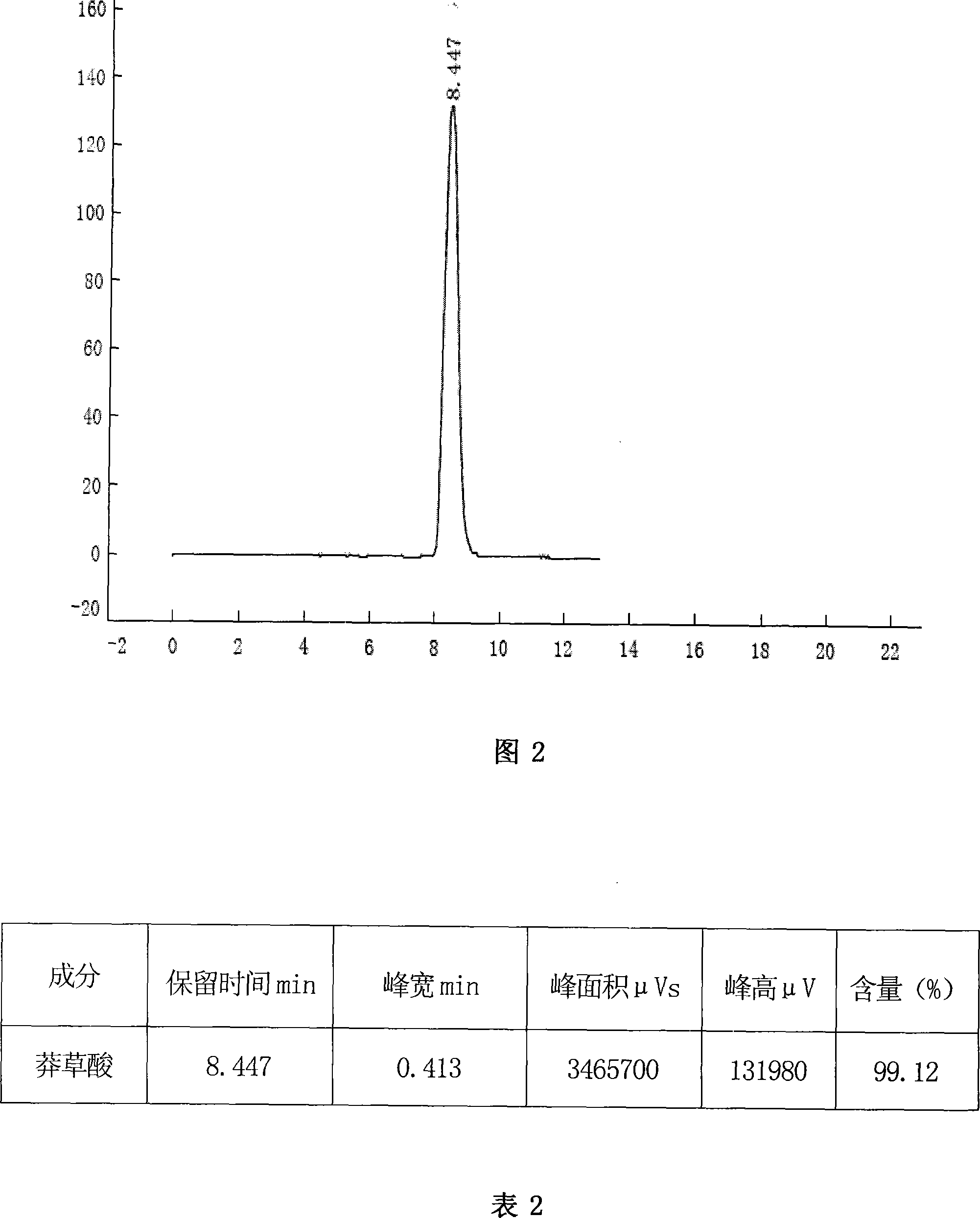

[0043] Example 2: Take 1000 kg of pulverized star anise raw material, degrease with petroleum ether with a horizontal rotary extractor, extract the degreased material with 5 times the volume of 90% ethanol under heat reflux for 3 times, each time for two hours, and combine the extractions liquid, filtered and concentrated to a relative density of 1.20. Add 3 times the amount of water, decolorize with 5% activated carbon at 80°C until the liquid turns pale yellow, concentrate under reduced pressure to a relative density of 1.20, place at room temperature for 48 hours, centrifuge, and filter to obtain crude crystals. The crude crystals were dissolved in 85% ethanol, decolorized with 5% activated carbon until colorless, concentrated to a relative density of 1.22, left to crystallize for 36 hours, centrifuged, filtered, and dried to obtain 56.4 kg of shikimic acid product. The shikimic acid content is 99.12%. The content of shikimic acid is shown in Figure 2 and Table 2.

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com