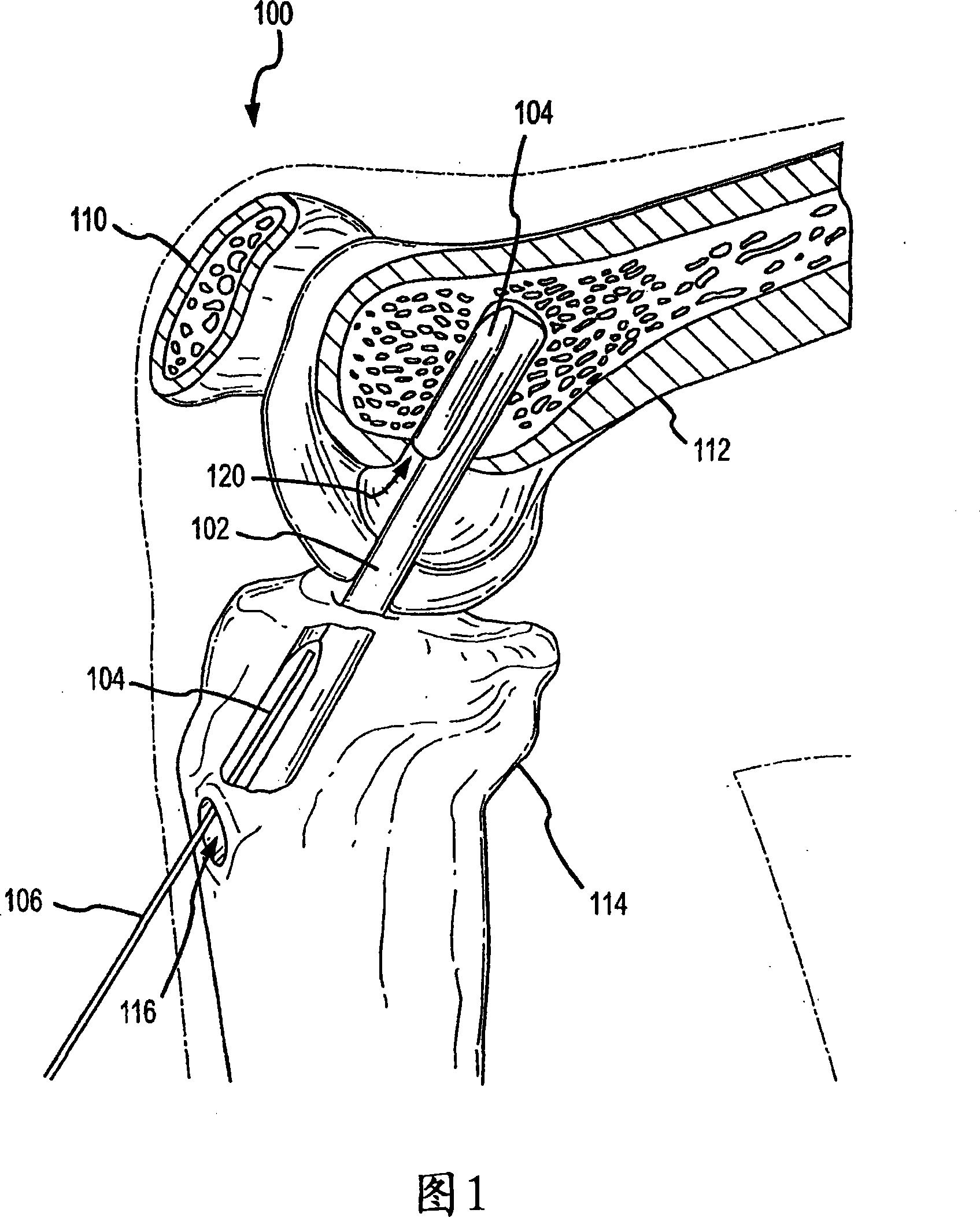

A graft fixation device and method

A bone implant and pre-implantation technology, applied in spinal implants, pharmaceutical formulations, drug delivery, etc., can solve problems such as the complexity of popliteal tendon fixation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

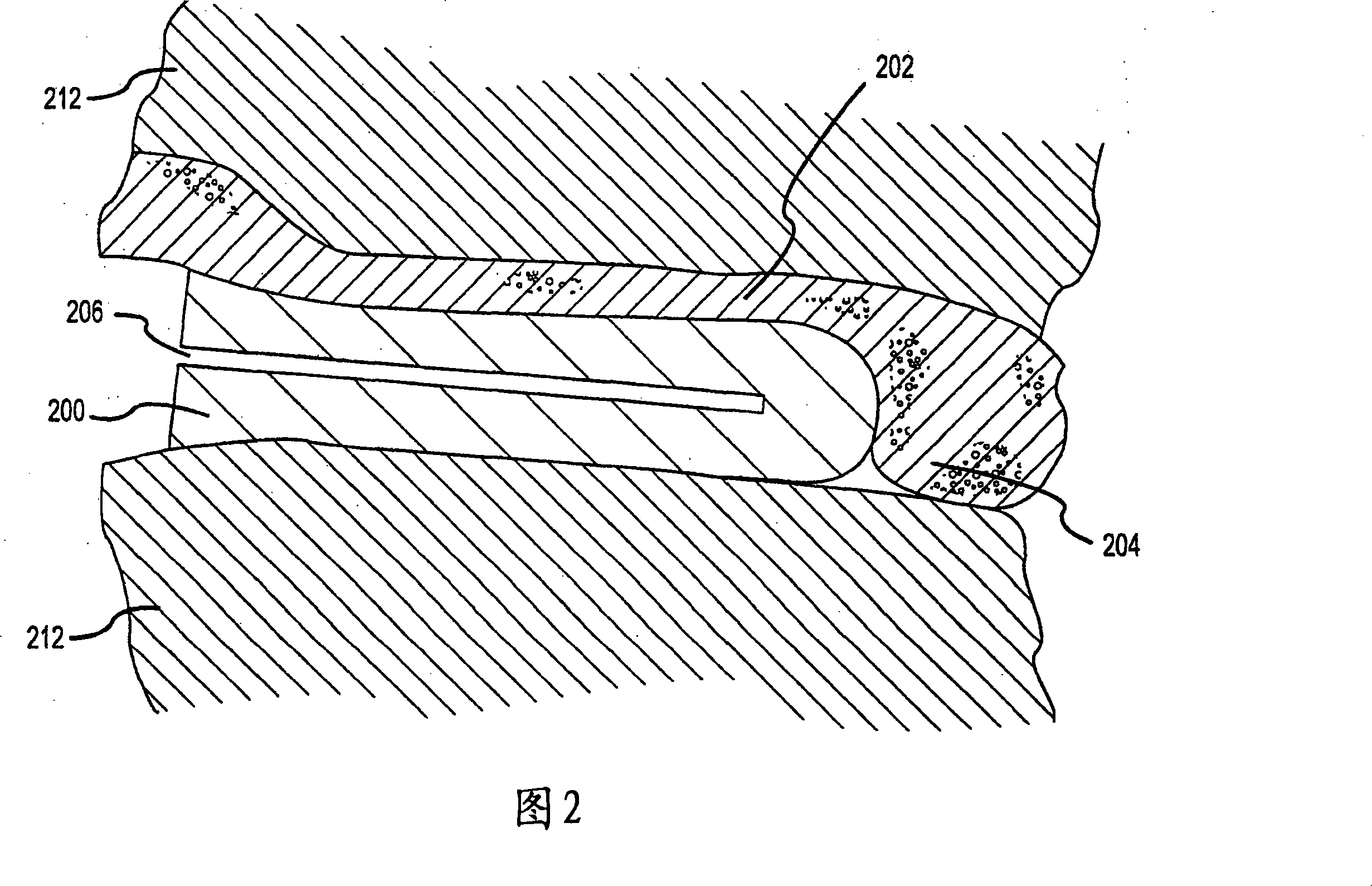

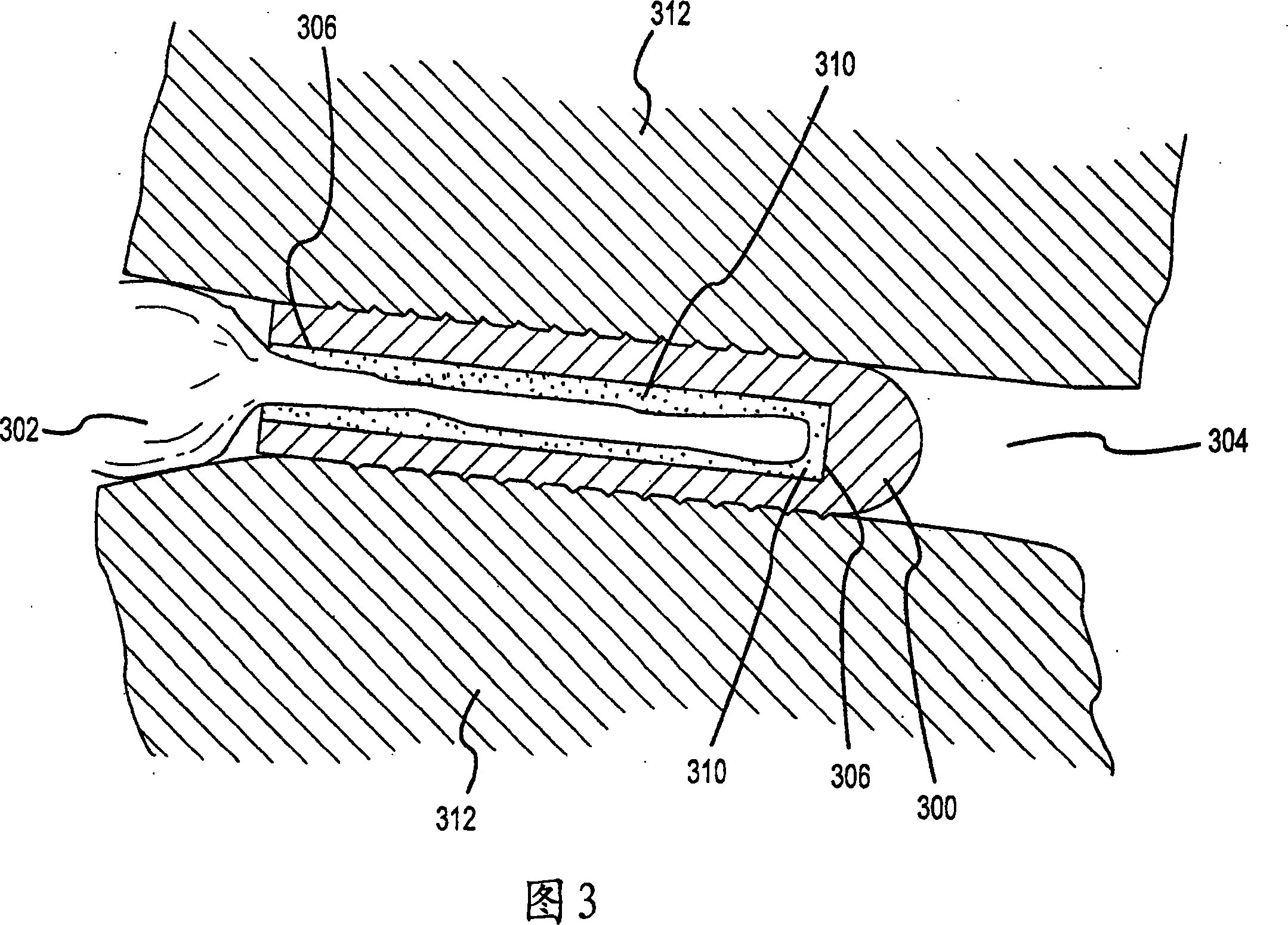

Method used

Image

Examples

example 1

[0158] Example 1. SMP production

[0159] tert-butyl acrylate (tBA) monomer (Aldrich), poly(ethylene glycol) dimethacrylate (PEGDMA) crosslinker (Aldrich), and photoinitiator 2,2-dimethoxy-2-benzene Acetophenone (Aldrich) was used as obtained without further purification. A polymer solution was prepared by combining 10 wt% PEGDMA, .1 wt% initiator, and the balance tBA. Other crosslinker / monomer ratios are contemplated, and the crosslinker can be used in the range of 1 wt% to 99 wt%. Other photoinitiators include acetophenone, anisoin, anthraquinone, benzene chromium tricarbonyl, benzil, benzoin, benzoin ethyl ether, benzoin isobutyl ether, benzoin iso Methyl ether, benzophenone, 4-benzoyldiphenyl, 2-benzyl-2-(dimethylamino)-4′-morpholinobutyrophenone, 4,4′-bis(diethyl Amino)-4'-benzophenone, 4,4'-bis(dimethylamino)-4'benzophenone, camphorquinone, 2-chlorothioxanth-9-one, dibenzocycloheptatriene Ketone, 2,2-diethoxyacetophenone, 4,4'dihydroxybenzophenone, 4-(dimethylamino...

example 2

[0163] Example 2. SMP thermomechanical characteristics

[0164] The polymer samples were examined using a Perkin Elmer Dynamic Mechanical Analyzer (DMA-7). A three-point bending configuration was used for glass transition (Tg), strain recovery, and stress recovery tests (FIG. 24 inset). Three-point flexural loading allows reasonable stress / strain levels for samples across the temperature range from the glass to the rubber state. Specifically, this configuration allowed for a maximum bending strain of 30% over a span of 5 mm during stress and strain recovery testing. Figure 24 shows a comparison between PEGDMA copolymer and PLA, a biodegradable polymer used in tibial devices. The decrease in storage modulus with increasing temperature indicates that the material can transition from a glassy or rigid state to a rubbery state. Alternatively, Tg can be determined relative to the peak of the tan delta curve.

[0165] The glass storage modulus is an indicator of the hardness o...

example 3

[0167] Example 3. Plunger Production

[0168]Test plunger materials were machined with ratios of 45 wt% PEGDMA to 55% PMMA (polymethyl methacrylate) with 0.1% photoinitiator and mixed in 14 mm diameter glass test tubes. The open end of the test tube was closed with a rubber stopper, and the test tube and solution were placed in a water bath at 0° C. under a UV lamp for 10 minutes. The glass test tube was then removed, leaving a 14 mm cylinder of PEGPMMA with a glass transition temperature (Tg) of 40°C. The plungers were machined with a cylindrical batch machine using coconut oil as lubricant and a shaft speed of 450 RPM to a diameter of approximately 11.5 mm and a length of 25.4 mm. The edges of the device were trimmed to a radius of 0.5 mm to ensure that the device did not shear the soft tissue (tendon) it contacted.

[0169] In addition, various unconstrained (undeformed) shapes were formed in order to demonstrate the variety of possible unconstrained shapes, see FIG. 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com