Method for producing micro-structure controllable porous ceramic with agglutinating mould plate method

A technology of porous ceramics and template method, which is applied in the preparation of porous ceramics and the field of controllable porous ceramics, which can solve the problems of poor mechanical properties, serious stress concentration, and many pore wall defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

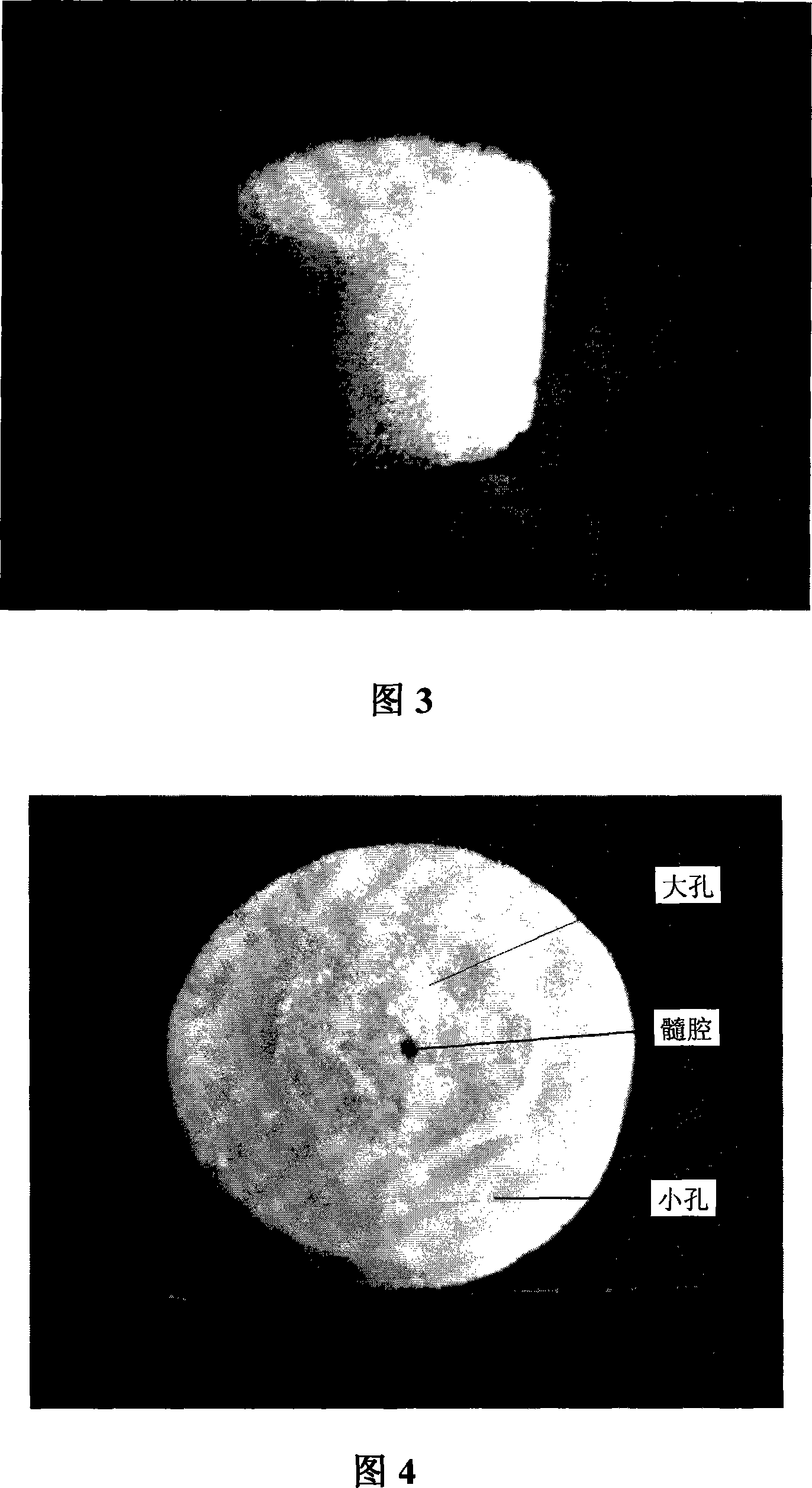

[0031] To make porous ceramic products as shown in Figure 3, the raw material is pure alumina, which requires a diameter of 30 mm, a thickness of 7 mm, a porosity of more than 70%, a large pore diameter of about 500 μm, and a connection diameter of 120 μm. Specific steps are as follows:

[0032] (1) Make a plastic mold with an inner diameter of 35mm and a height of 20mm, and touch bolts up and down.

[0033] (2) Use standard sieves to screen out polystyrene particles with a diameter of 500-600 μm.

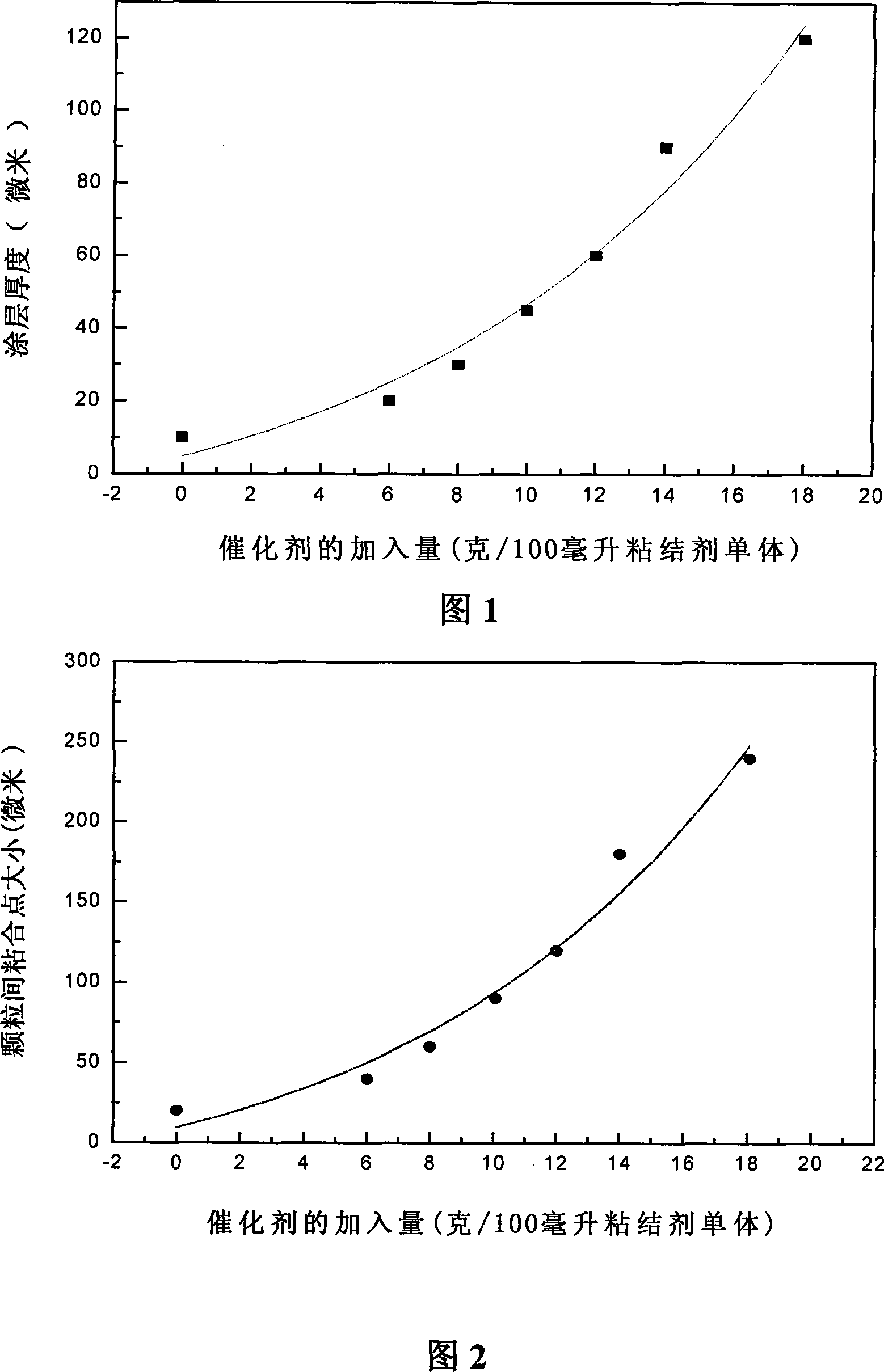

[0034] (3) According to Fig. 2, add 12 grams of benzoyl peroxide catalyst in 100 ml methyl methacrylate (MMA) binder, mix evenly and react completely.

[0035] (4) Add the prepared binder to the selected polystyrene granules, the amount of binder added is 10ml / 100g plastic granules, and the plastic granules and the binder are evenly mixed for 3 minutes.

[0036] (5) Put the polystyrene particles coated with adhesive on the surface into the mould, pressurize the upper mold plug at 0...

Embodiment 2

[0041] Make a porous gradient bioceramic product with small outer holes and large core holes as shown in Figure 4. The outer layer is small holes and has a certain mechanical strength, and the other parts are large holes that will guide the attachment of cells and the direction of new blood vessels. There is a medullary cavity in the center, which is conducive to obtaining sufficient blood supply and nutrition. The raw material is pure β-tricalcium phosphate, which requires a diameter of 30mm, a thickness of 7mm, a porosity of more than 70%, a large pore diameter of about 600μm, and a connecting neck of 180μm. Specific steps are as follows:

[0042] (1) Make a plastic mold with an inner diameter of 35mm and a height of 20mm, and touch bolts up and down.

[0043] (2) Use a standard type of sieve to screen out polystyrene particles with a diameter of 600-700 μm and a diameter of 100-150 μm, respectively.

[0044] (3) according to Fig. 2, add the benzoyl peroxide catalyst of 14...

Embodiment 3

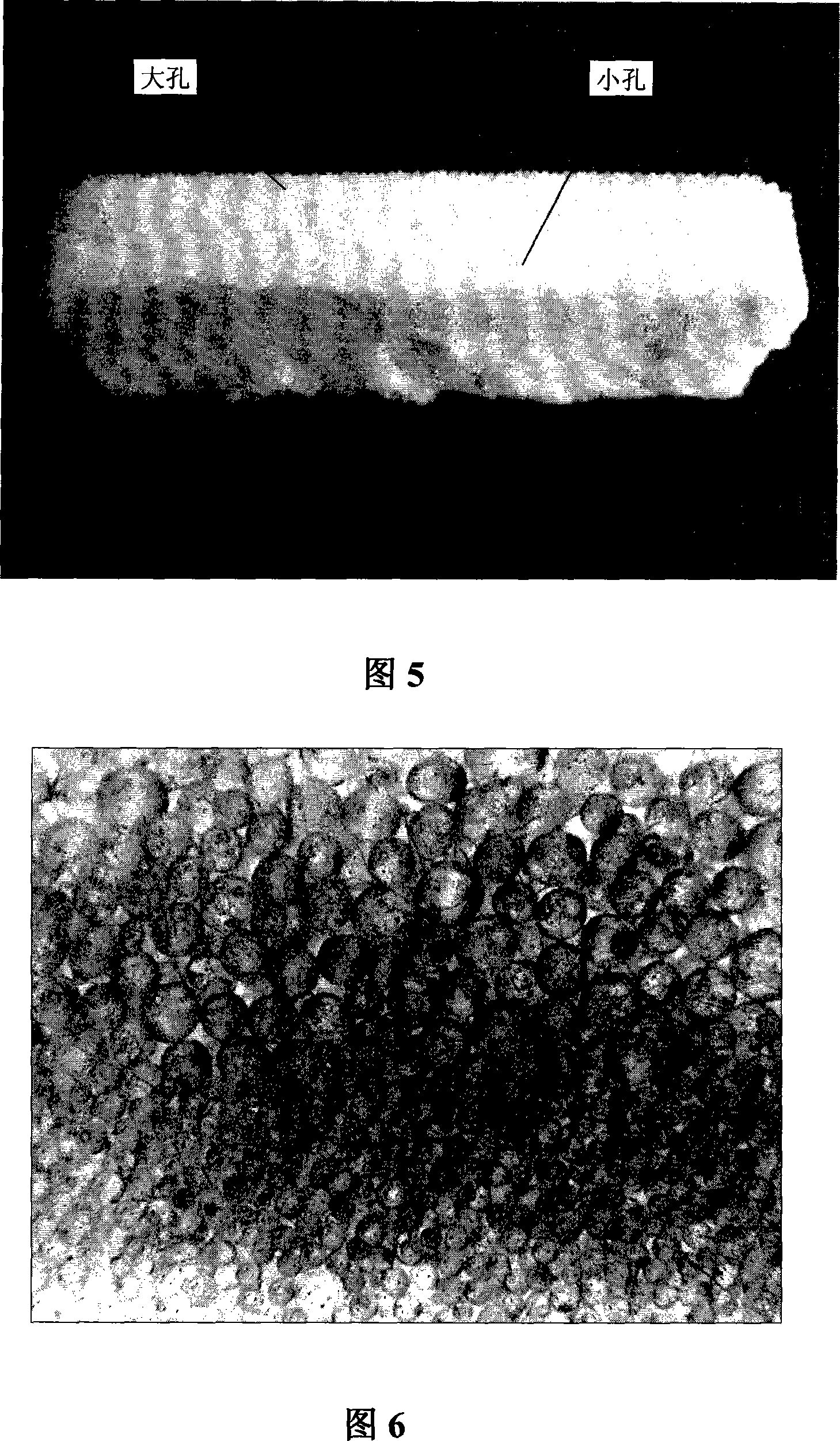

[0051] To produce the porous gradient ceramic block-shaped product as shown in Figure 5, the raw material is CaO-stabilized zirconia, and the length, width and height are required to be 50mm, 10mm and 20mm respectively. The porosity is more than 70%, the diameter of the macropore is about 500 μm, and the connection neck in the hole is 60 μm. Specific steps are as follows:

[0052] (1) Make plastic molds with length, width and height of 60mm, 30mm and 15mm respectively.

[0053] (2) Using a standard type of sieve, sieve out polyethylene particles with a diameter of 500-600 μm and a diameter of 50-100 μm, respectively.

[0054] (3) According to Figure 2, add 8 grams of benzoyl peroxide catalyst to 100 ml of methyl methacrylate (MMA) binder, mix evenly and react completely.

[0055] (4) Add the prepared methyl methacrylate binder to the selected polystyrene granules of two sizes. The amount of the binder is 10ml / 100g of the plastic granule quality. Mix the agent thoroughly and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com