Stable inorganic-base organic composite solid adjustable dye laser medium

A laser medium and organic technology, applied in the field of stable inorganic-based organic composite solid-state tunable dye laser media, can solve the problem of poor composition and microstructure uniformity of inorganic-based organic composite solid-state tunable dye laser media, difficulty in long-term, stable operation, and process Poor adaptability and other problems, to achieve the effect of improving the anti-photochemical degradation performance, increasing the laser output life, and uniform composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition (moles) of the precursor solution is: methyltriethoxysilane (CH 3 Si(OC 2 h 5 ) 3 ) 10±4mol, ethanol 38±5mol, deionized water 40±4mol, pyrrole methylidene 567 (P-567) laser dye 100±50mmol. Dissolve methyltriethoxysilane in ethanol, add the ethanol solution of P-567 laser dye at 20°C to 70°C, stir for 30 to 100 minutes, add deionized water dropwise, and adjust the pH value of the mixture with hydrochloric acid 1 to 4, continue stirring for 2 to 6 hours to hydrolyze vinyltriethoxysilane. Then add alkali polycondensation catalyst 3-aminopropyltriethoxysilane (NH 2 (CH 2 ) 3 Si(OC 2 h 5 ) 3 ), adjust the pH value of the mixture to 4-7, and continue stirring for 1-4 hours. The mixed liquid is left standing in the environment of 30 DEG C to 70 DEG C, and after 10 to 40 days, the P-567 laser dye-doped inorganic-based organic composite solid-state tunable dye laser medium is prepared.

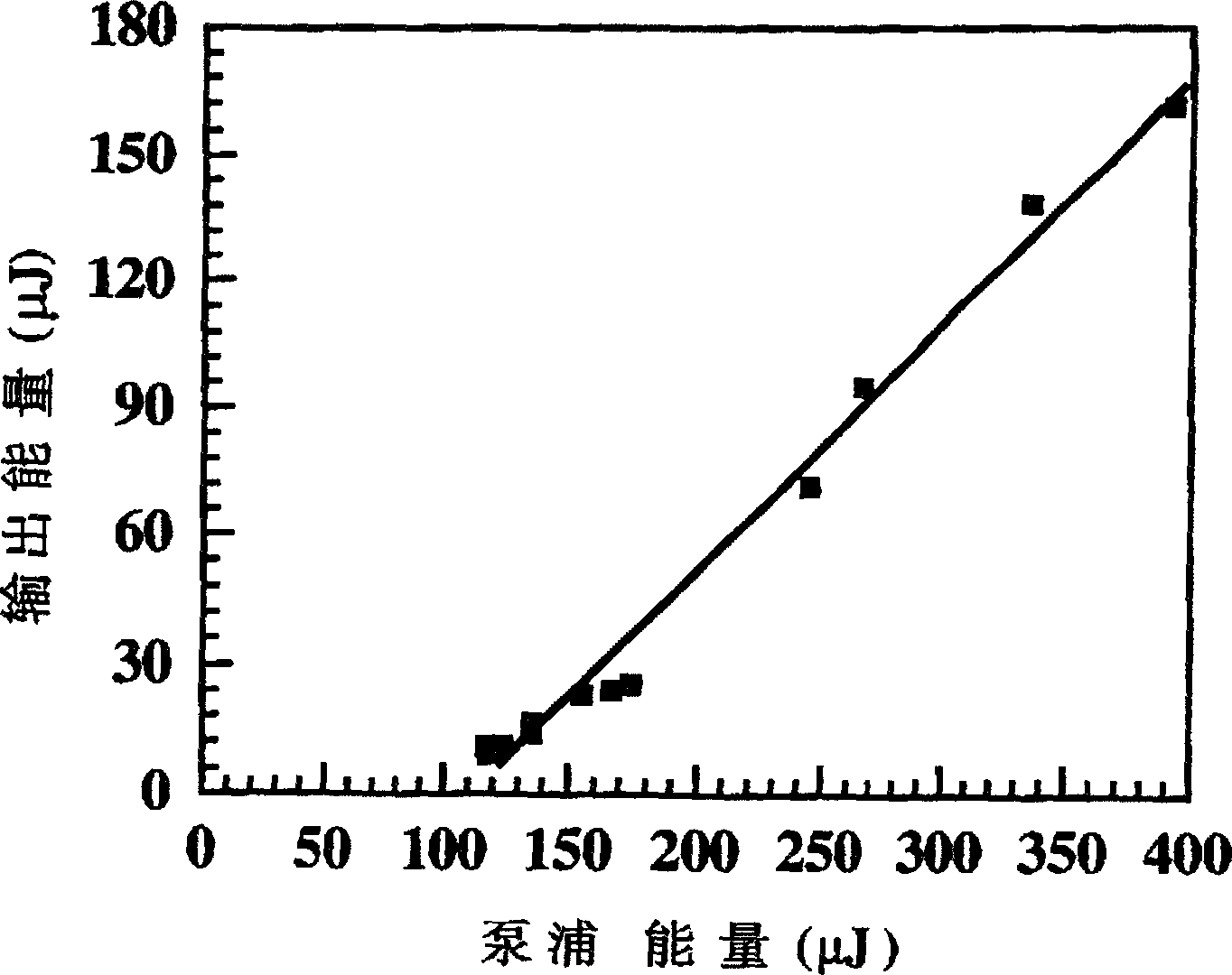

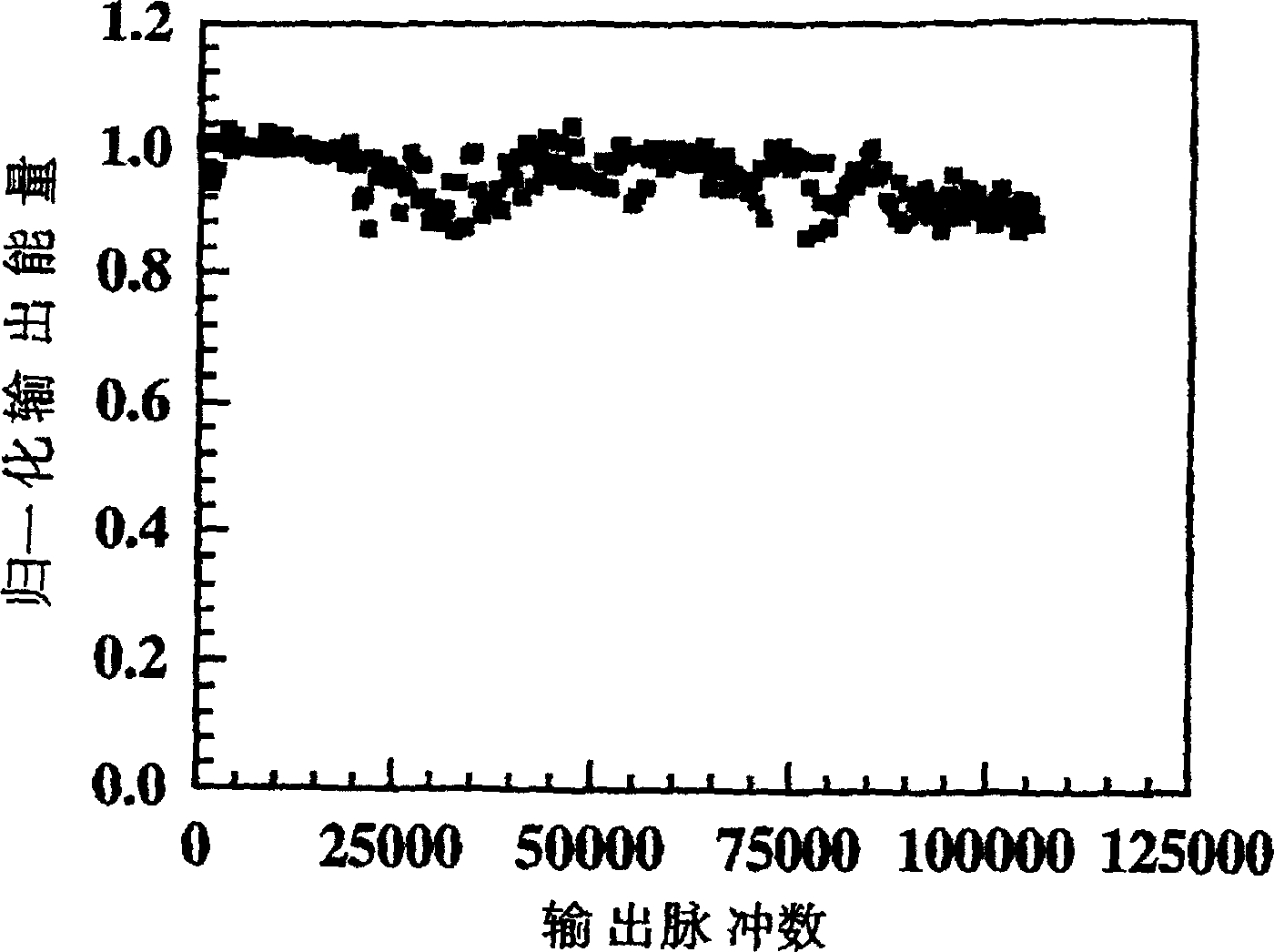

[0026] The composite solid-state laser medium prepared by this st...

Embodiment 2

[0028] The composition (number of moles) of the precursor solution is: vinyltriethoxysilane (H 2 C=CHSi(OC 2 h 5 ) 3 ) 10±4mol, ethanol 38±5mol, deionized water 40±4mol, perylene orange (P-orange) laser dye 100±50mmol. Dissolve vinyltriethoxysilane in ethanol, add the ethanol solution of P-orange laser dye at 20°C to 70°C, stir for 30 to 100 minutes, add deionized water dropwise, and adjust the pH value of the mixture with hydrochloric acid 1 to 4, continue stirring for 2 to 6 hours to hydrolyze vinyltriethoxysilane. Then add alkali polycondensation catalyst N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (H 2 N(CH 2 ) 2 NH(CH 2 ) 3 Si(OCH 3 ) 3), adjust the pH value of the mixture to 4-7, and continue stirring for 1-4 hours. The mixed solution is left standing in the environment of 30 DEG C to 70 DEG C, and after 10 to 40 days, the P-orange laser dye-doped inorganic-based organic composite solid-state tunable dye laser medium is prepared.

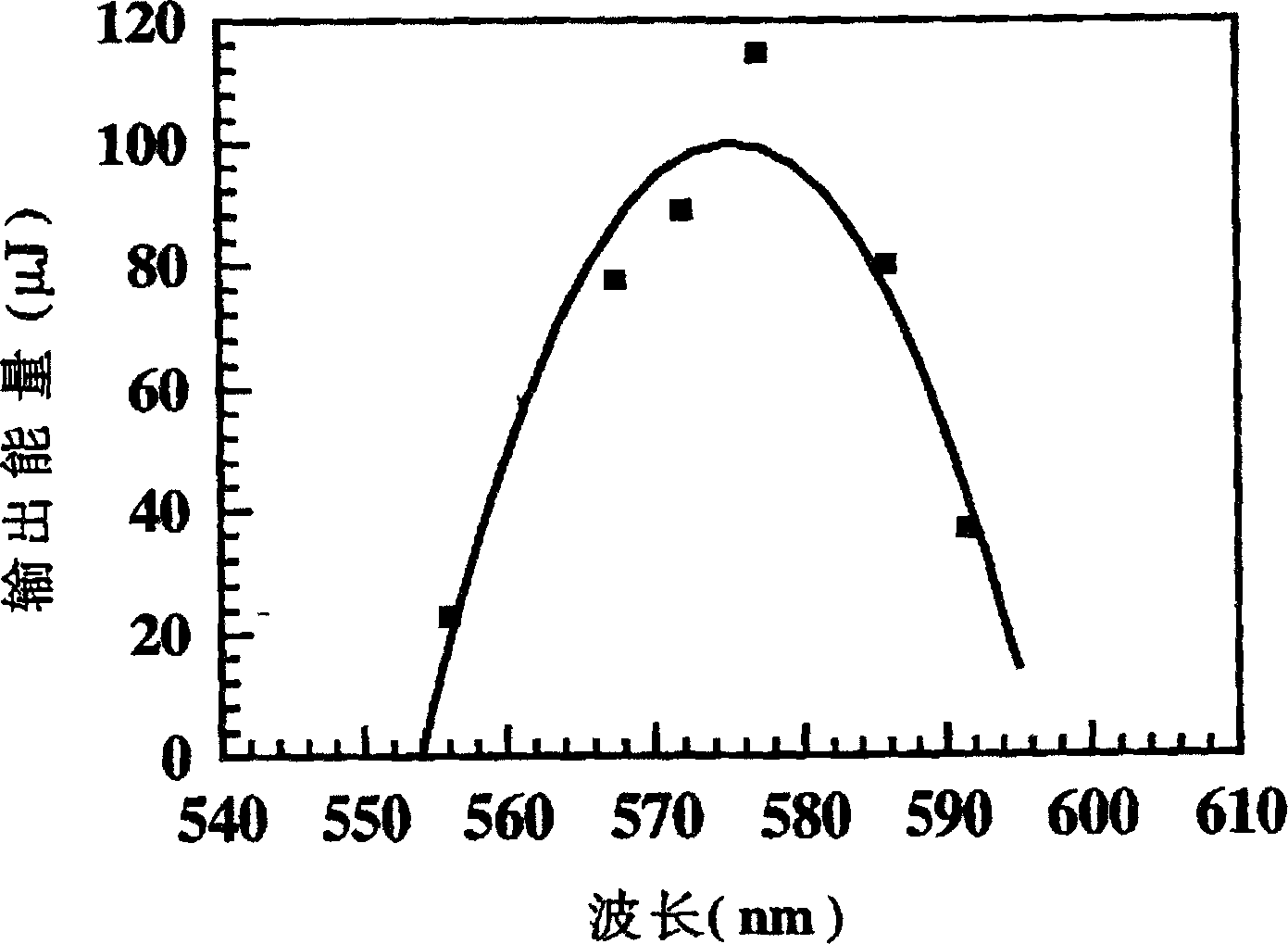

[0029] The composite sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com