Stepped synthesis process of preparing stable inorganics-based composite solid tunable dye laser medium

A laser medium, step-by-step synthesis technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problem of poor composition and microstructure uniformity of inorganic-based organic composite solid-state tunable dye laser medium, difficulty in long-term, stable operation, process adaptation In order to improve the anti-photochemical degradation performance, improve the laser output life, and achieve the effect of uniform composition and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a wet chemical preparation technology of step-by-step synthesis, and its main technical characteristics are: using a precursor with a small organic group, in an organic solvent, adopting a step-by-step process of acid-catalyzed hydrolysis and then alkali-catalyzed polycondensation Synthesis technology, the molecular level of organic laser dyes is dispersed in the inorganic matrix modified by small organic groups, and a new method for the preparation of stable inorganic-based organic composite solid-state tunable dye laser media is developed. Using this method, the composition and microstructure uniformity, compactness and photochemical decay resistance of the composite laser medium can be effectively modulated and improved, the optical processing performance of the composite material can be improved, and the laser output stability of the composite solid-state dye laser medium can be significantly improved. Performance, efficiency, life and other co...

Embodiment 1

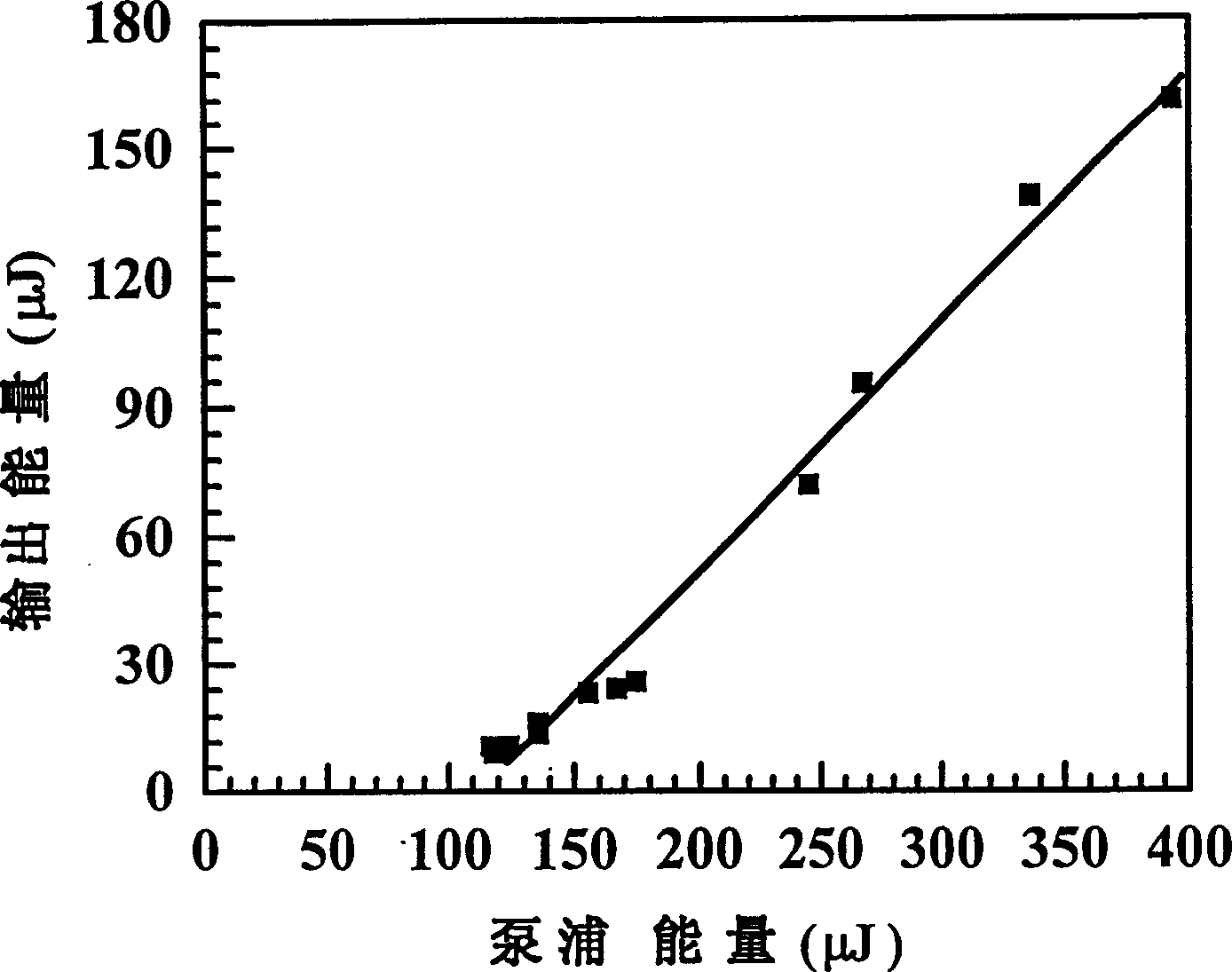

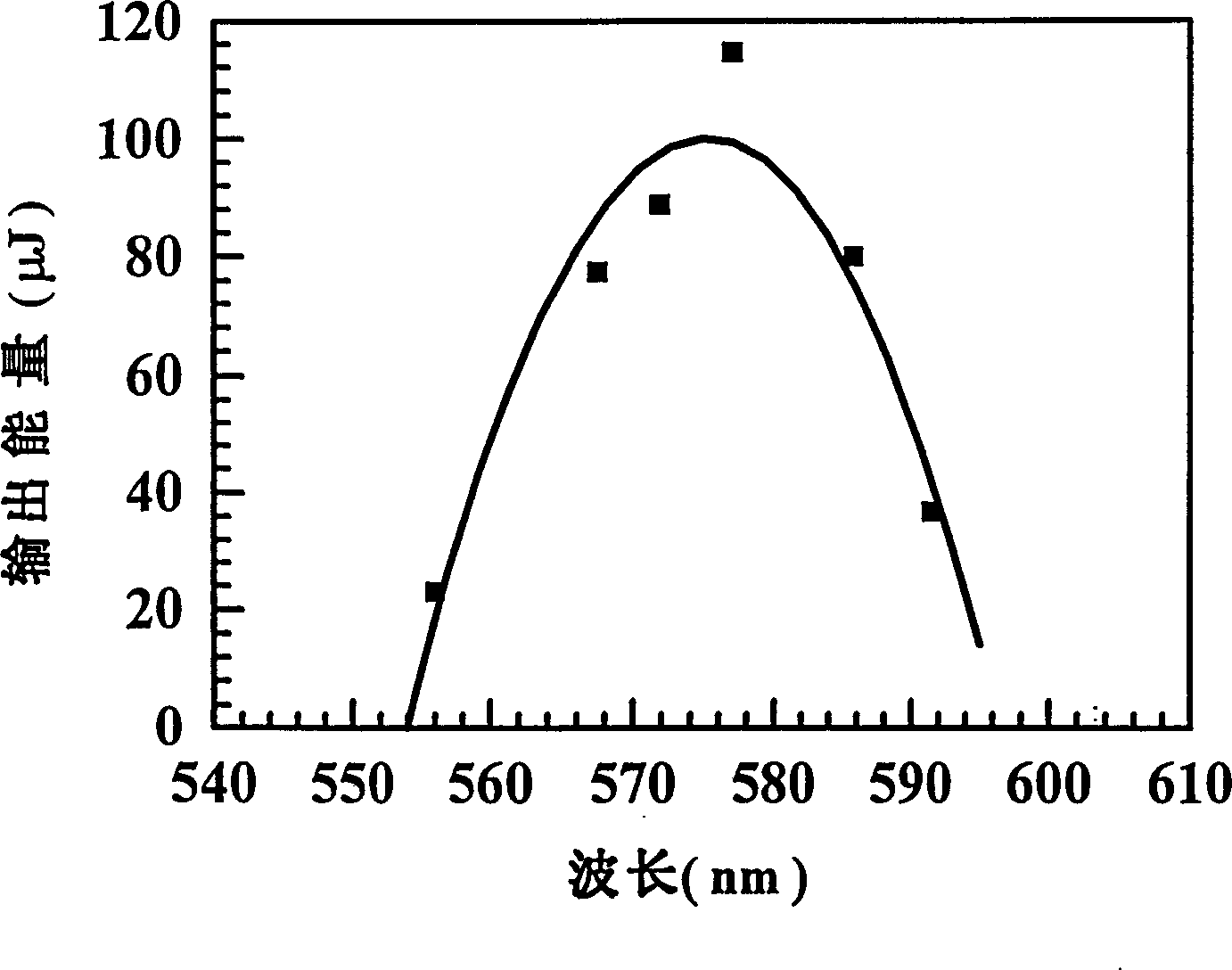

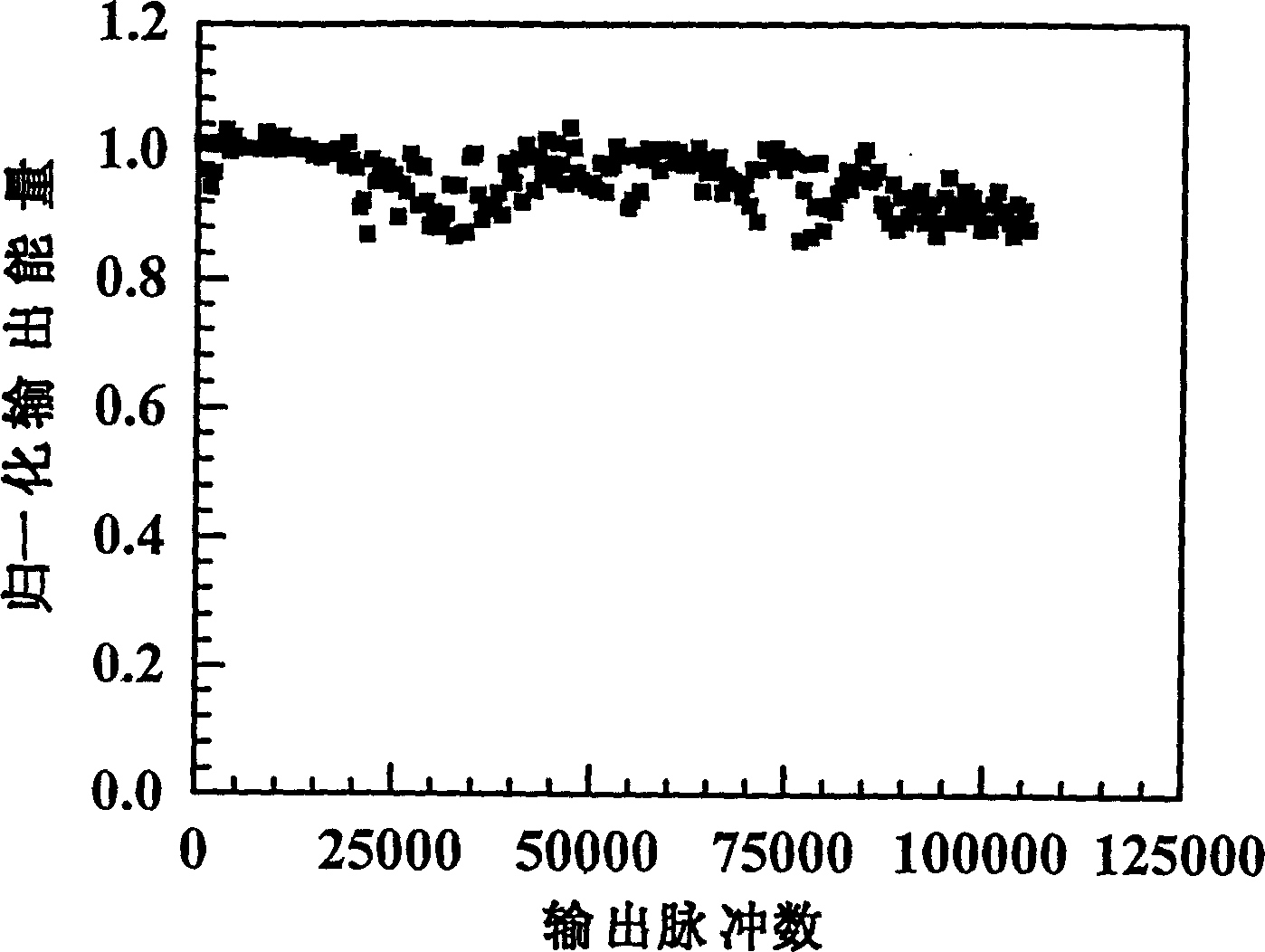

[0019] The composition (moles) of the precursor solution is: methyltriethoxysilane (CH 3 Si(OC 2 h 5 ) 3 ) 10±4mol, ethanol 38±5mol, deionized water 40±4mol, pyrrole methylidene 567 (P-567) laser dye 100±50mmol. Dissolve methyltriethoxysilane in ethanol, add the ethanol solution of P-567 laser dye at 20°C to 70°C, stir for 30 to 100 minutes, add deionized water dropwise, and adjust the pH value of the mixture with hydrochloric acid 1 to 4, continue stirring for 2 to 6 hours to hydrolyze vinyltriethoxysilane. Then add alkali polycondensation catalyst 3-aminopropyltriethoxysilane (NH 2 (CH 2 ) 3 Si(OC 2 h 5 ) 3 ), adjust the pH value of the mixture to 4-7, and continue stirring for 1-4 hours. The mixed liquid is left standing in the environment of 30 DEG C to 70 DEG C, and after 10 to 40 days, the P-567 laser dye-doped inorganic-based organic composite solid-state tunable dye laser medium is prepared. The composite solid-state laser medium prepared by this step-by-ste...

Embodiment 2

[0021] The composition (number of moles) of the precursor solution is: vinyltriethoxysilane (H 2 C=CHSi(OC 2 h 5 ) 3 ) 10±4mol, ethanol 38±5mol, deionized water 40±4mol, perylene orange (P-orange) laser dye 100±50mmol. Dissolve vinyltriethoxysilane in ethanol, add the ethanol solution of P-orange laser dye at 20°C to 70°C, stir for 30 to 100 minutes, add deionized water dropwise, and adjust the pH value of the mixture with hydrochloric acid 1 to 4, continue stirring for 2 to 6 hours to hydrolyze vinyltriethoxysilane. Then add alkali polycondensation catalyst N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (H 2 N(CH 2 ) 2 NH(CH 2 ) 3 Si(OCH 3 ) 3 ), adjust the pH value of the mixture to 4-7, and continue stirring for 1-4 hours. The mixed solution is left standing in the environment of 30 DEG C to 70 DEG C, and after 10 to 40 days, the P-orange laser dye-doped inorganic-based organic composite solid-state tunable dye laser medium is prepared.

[0022]The composite sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com