Method for preparing ZnO nanowire array

A chemical method and aqueous solution technology, which is applied in the field of controllable preparation of acicular and hexagonal columnar ZnO nanowire arrays, can solve the problems of limitation, long reaction time, and low deposition rate, and achieve low cost, easy operation, and high deposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Cut the glass into a substrate with a size of 12×24×0.5mm, and plate Ag on the glass substrate according to the following method: ultrasonically clean the glass substrate in distilled water, alcohol, and acetone solutions to remove impurities and oil stains on the surface;

[0027] Immerse the cleaned substrate into 5-10g / l SnCl at room temperature 2 In the sensitizing solution mixed with 0.08M hydrochloric acid, soak for 0.5 to 8 minutes;

[0028] After taking it out, immerse it in distilled water for about 2 to 40 seconds;

[0029] Then take it out, and then immerse the glass substrate into 1-10g / l normal temperature AgNO 3 In the activated water solution, soak for 1 to 10 minutes;

[0030] Repeat steps b-d several times until the glass substrate material changes from bright and transparent to brown, indicating that the activation is successful.

[0031] The core of the above steps is to generate a Sn 2+ Reduced Ag + It is the oxidation-reduction reaction of simp...

Embodiment 2

[0035] The preparation of the Ag-coated glass substrate was the same as in Example 1.

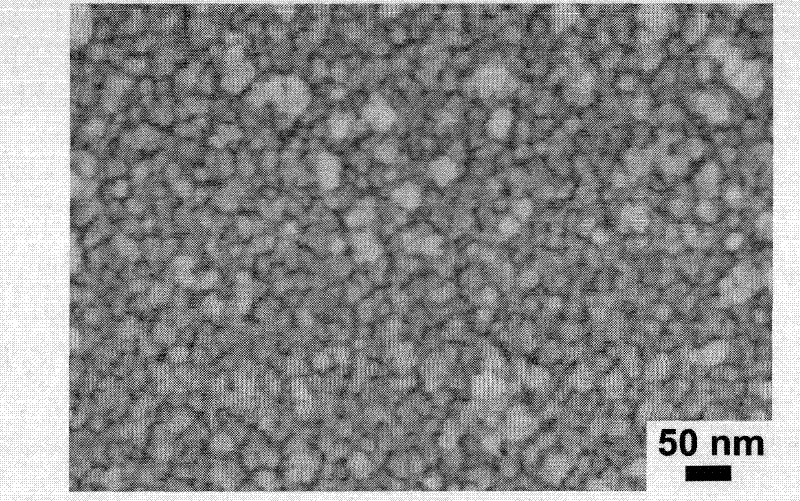

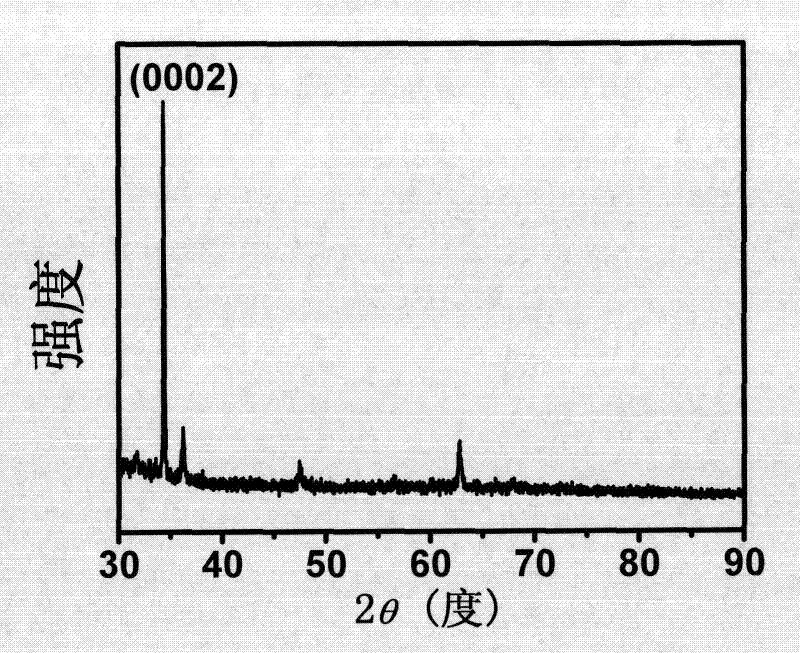

[0036] Prepare 50mM Zn(NO 3 ) 2 Mix 50ml of solution with 10mM DMAB, place in a 90°C water bath, immerse the substrate in it, and react for 30 minutes to form a hexagonal columnar ZnO nanowire array. SEM photos are attached Figure 4 , it can be seen that the diameter of the nanowire is 80nm and the length is about 300nm.

[0037] The condition for generating hexagonal columnar ZnO nanowire arrays is to control the Zn(NO 3 ) 2 The concentration is between 20-70mM. We found experimentally that more than 80mM Zn(NO 3 ) 2 Concentration is not conducive to obtaining nanowire arrays, but will prepare sheet or polycrystalline ZnO thin films.

Embodiment 3

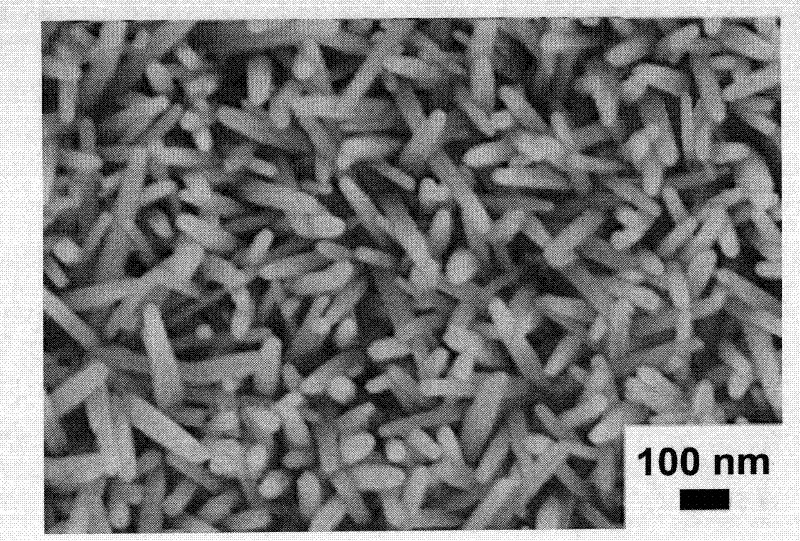

[0039] A Cu sheet (15×15×0.7 mm) polished with 1500 mesh sandpaper was immersed in the solution described in Example 1, and kept in a water bath at 90° C. for 30 minutes. SEM photos are attached Figure 5 , the plush surface is the needle-shaped ZnO nanowire array, with an average diameter of 40nm and a length of about 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com