Method for producing temperature sensing polymer gel microsphere

A temperature-sensitive polymer and gel microsphere technology, which is applied in the field of preparation of temperature-sensitive polymer gel microspheres, achieves the effects of uniform gel distribution, wide application prospects, and high input-output ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

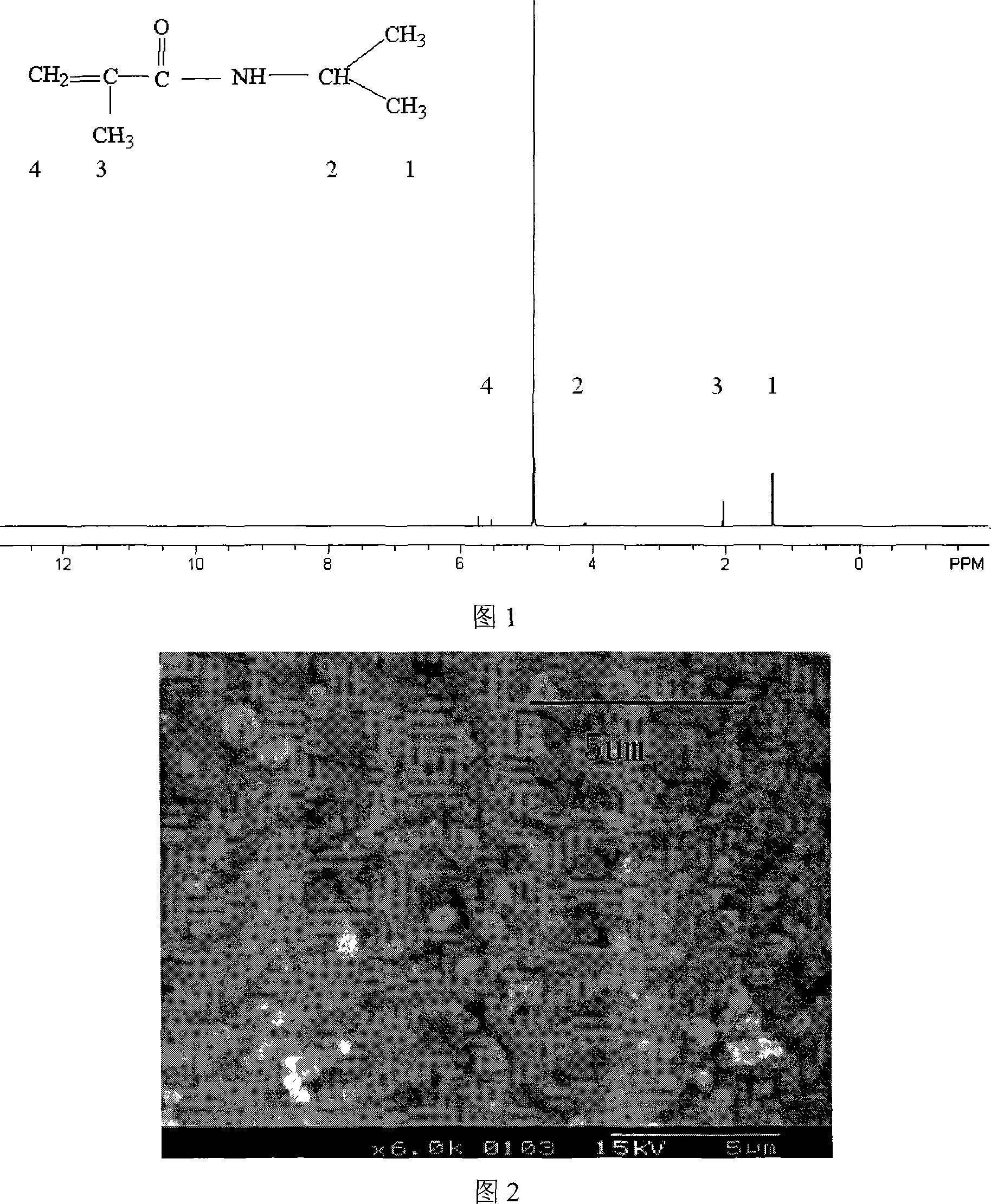

Embodiment 1

[0022] Put 83ml (92.3g, 0.996mol) of methacryloyl chloride and 100ml ethyl acetate in a 250ml constant pressure funnel, and mix well. Measure 105ml (72.9g, 1.24mol) of isopropylamine, 167ml (121g, 1.19mol) of triethylamine and 300ml of ethyl acetate into a 1000ml three-necked bottle, stir evenly, and dissolve the methyl alcohol through a funnel under an ice-water bath. The mixed solution of acryloyl chloride and ethyl acetate was slowly dropped into the three-necked bottle (keep the temperature in the bottle below 5°C), and after the dropwise addition was completed, the stirring reaction was continued for 6 hours (the temperature rose to 5-10°C). After the filtrate was obtained by filtration, it was concentrated to dryness under reduced pressure to obtain a reddish-brown viscous liquid, namely crude N-isopropylmethacrylamide. Then add the obtained N-isopropylmethacrylamide crude product into a large amount of ethyl acetate to dissolve, filter to obtain the filtrate, and then c...

Embodiment 2

[0025] Same as Example 1, but methacryloyl chloride becomes acryloyl chloride, and the number of moles remains unchanged.

Embodiment 3

[0027] The same as Example 1, but when refining N-isopropylmethacrylamide, the filtrate was concentrated to 10% by rotary evaporation using a rotary evaporator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com